| ID |

Date |

Author |

Project |

Subject |

Run Number |

Events |

StartTime |

EndTime |

|

62

|

Sat Aug 22 09:44:50 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 31,8 MHz hit mode (cooling?) | run016 | 75k | 22.08.2009 09:42:38 | 22.08.2009 10:24:05 |

HV=80V, 31.8 MHz, beam on, 120 GeV

6 samples, hit mode, hitcut=5

chiller set to 13 deg.

f=31.8 MHz

config file: cern09_belle_31.8mhz_hit_cut5_multi6.cfg

there was probably no water flow throught the pipe of the origami module during this run!

|

|

63

|

Sat Aug 22 10:28:50 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 40 MHz hit mode (cooling?) | run017 | 75k | 22.08.2009 10:26:28 | 22.08.2009 11:16:12 |

HV=80V, 40 MHz, beam on, 120 GeV

6 samples, hit mode, hitcut=4

chiller set to 13 deg.

f=40 MHz

config file: cern09_belle_hit_multi6.cfg

there was probably no water flow throught the pipe of the origami module during this run!

|

|

64

|

Sat Aug 22 11:26:00 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 40 MHz hit mode (cooling?) | run018 | 75k | 22.08.2009 11:16:57 | 22.08.2009 11:58:56 |

HV=80V, 40 MHz, beam on, 120 GeV

6 samples, hit mode, hitcut=5

chiller set to 13 deg.

f=40 MHz

config file: cern09_belle_hit_cut5_multi6.cfg

trigger rate about 3500 ev / spill

there was probably no water flow throught the pipe of the origami module during this run!

|

|

66

|

Sat Aug 22 12:12:34 2009 |

Christian Irmler | BELLE | internal calibration 40 MHz transparent mode (cooling?) | cal007 | | 22.08.2009 12:10:32 | 22.08.2009 12:49:09 |

Belle DUT, intcal

HV=80V, 40 MHz, beam off

1 sample, transparent mode

chiller set to 13 deg.

external 40 MHz clock

there was probably no water flow throught the pipe of the origami module during this run --> must be repeated |

|

68

|

Sat Aug 22 13:30:28 2009 |

Christian Irmler | BELLE | internal calibration 31.8 MHz transparent mode (cooling?) | cal008 | | 22.08.2009 12:50:48 | 22.08.2009 13:29:25 |

Belle DUT, intcal

HV=80V, 31.8 MHz, beam off

1 sample, transparent mode

chiller set to 13 deg.

external 31.8 MHz clock

there was probably no water flow throught the pipe of the origami module during this run --> must be repeated |

|

69

|

Sat Aug 22 13:34:14 2009 |

Christian Irmler | BELLE | pedestal correction 31.8 MHz transparent mode (cooling?) | pedcorr005 | | 22.08.2009 13:31:27 | 22.08.2009 13:41:42 |

Belle DUT, intcal

HV=80V, 31.8 MHz, beam off

1 sample, transparent mode

chiller set to 13 deg.

external 31.8 MHz clock

there was probably no water flow throught the pipe of the origami module during this run --> must be repeated! |

|

70

|

Sat Aug 22 14:46:12 2009 |

Christian Irmler | BELLE | internal calibration 31.8 MHz transparent mode + cooling | cal009 | | 22.08.2009 14:43:55 | 22.08.2009 15:22:37 |

Belle DUT, intcal

HV=80V, 31.8 MHz, beam off

1 sample, transparent mode

cooling

chiller set to 13 deg.

Since there was no (or to less) water flow through the small pipe of the origami module, all previous runs with cooling must be repeated.

Bypass removed to achieve better watter flow at the module!

Chiller pump is set to 2800 rpm |

|

72

|

Sat Aug 22 15:28:00 2009 |

Christian Irmler | BELLE | pedestal correction 31.8 MHz transparent mode + cooling | pedcorr006 | | 22.08.2009 15:25:35 | 22.08.2009 15:36:00 |

Belle DUT, HV=80V, 31.8 MHz, beam off

1 sample, transparent mode

pedestal correction

chiller set to 13 deg, 2900 rpm |

|

73

|

Sat Aug 22 15:52:33 2009 |

Christian Irmler | BELLE | APVDAQ + telescope 31.8 MHz transparent mode + cooling | run019 | 75k | 22.08.2009 15:50:40 | 22.08.2009 19:14:21 |

Belle DUT, HV=80V, 31.8 MHz, 120 GeV

6 samples, transparent mode

chiller set to 13 deg, 2900 rpm

water flow checked befor start of run |

|

74

|

Sat Aug 22 19:19:20 2009 |

Christian Irmler | BELLE | APVDAQ + telescope 40 MHz transparent mode + cooling | run020 | 75k | 22.08.2009 19:17:29 | 22.08.2009 22:09:53 |

Belle DUT, HV=80V, 40 MHz, 120 GeV

6 samples, transparent mode

chiller set to 13 deg, 2900 rpm

water flow checked befor start of run |

|

75

|

Sat Aug 22 22:14:50 2009 |

Christian Irmler | BELLE | internal calibration 40 MHz transparent mode + cooling | cal010 | | 22.08.2009 22:24:22 | |

Belle DUT, intcal

HV=80V, 40 MHz, beam off

1 sample, transparent mode

external clock

cooling

chiller set to 13 deg.

Bypass removed to achieve better watter flow at the module!

Chiller pump is set to 2800 rpm |

|

76

|

Sat Aug 22 23:06:22 2009 |

Christian Irmler | BELLE | pedestal correction 40 MHz transparent mode + cooling | pedcorr007 | | 22.08.2009 23:04:29 | 22.08.2009 23:13:51 |

Belle DUT, HV=80V, 40 MHz, beam off

1 sample, transparent mode

pedestal correction

chiller set to 13 deg, 2900 rpm |

|

103

|

Tue Aug 25 20:21:31 2009 |

Christian Irmler | BELLE | APVDAQ + telescope 40 MHz transparent mode | run042 | 85189 | 25.08.2009 20:18:18 | 26.08.2009 01:27:12 |

Belle DUT, HV=80V, 40 MHz, 120 GeV

6 samples, transparent mode

no cooling

after realignement of modules

new beam spot:

APV #

|

n-side

|

p-side

|

JP

|

1/2

|

1/2

|

Origami

|

2/3

|

1/2 |

Flex

|

1/2

|

1/2 |

Micron

|

0/1

|

1/2 |

|

|

104

|

Wed Aug 26 01:32:25 2009 |

Christian Irmler | BELLE | APVDAQ + telescope 40 MHz transparent mode + cooling | run043 | 100600 | 26.08.2009 01:46:38 | 26.08.2009 07:10:14 |

Belle DUT, HV=80V, 40 MHz, 120 GeV

6 samples, transparent mode

w cooling, chiller set to 13 deg, 2900 rpm

after realignement of modules

new beam spot:

APV #

|

n-side

|

p-side

|

JP

|

1/2

|

1/2

|

Origami

|

2/3

|

1/2 |

Flex

|

1/2

|

1/2 |

Micron

|

0/1

|

1/2 |

|

|

105

|

Wed Aug 26 07:19:42 2009 |

Christian Irmler | BELLE | APVDAQ + telescope 31.8 MHz transparent mode + cooling | run044 | 13504 | 26.08.2009 07:18:19 | 26.08.2009 08:46:11 (beam shut down @ 8:00) |

Belle DUT, HV=80V, 31.8 MHz, 120 GeV

6 samples, transparent mode

w cooling, chiller set to 13 deg, 2900 rpm

after realignement of modules

new beam spot:

APV #

|

n-side

|

p-side

|

JP

|

1/2

|

1/2

|

Origami

|

2/3

|

1/2 |

Flex

|

1/2

|

1/2 |

Micron

|

0/1

|

1/2 |

|

|

6

|

Mon Jul 6 14:30:45 2009 |

Marko Dragicevic | | Equipment List | | | | |

Slow Control:

Source Measurement Unit Keithley K2410, Inv.Nr.: 540-702, 2000EUR

-- Koax-Kabel + Adapter auf Banane

Scanning Voltmeter Keithley K2700 , Inv.Nr.: 540-698, 2000EUR

-- Shunt-Widerstand-Platine

-- Flachbandkabel fuer Verbindung Shunt-Platine<->K2700

TRHX

-- 3 Sensoren

-- 2 lange Flachbandkabel, 1 serielles Kabel

LV-Power-Supplies, je 150EUR

-- GW Instek GPC-1850, SN.: 4080392

-- GW Instek GPC-1850D, Inv.Nr.: 545-059

-- GW Instek GPC-1850D, Inv.Nr.: 545-062

-- Systron Donner HR 20-10A, SN.: 781-092

-- Systron Donner HR 20-10A, SN.: 781-096

Oszilloskop Tektronix TDS 3054, SN.: B011109, 4000EUR

-- 4 probes

Die Katze (Belle-HV-Supply)

-- HV-Kabel 30m

GBIP-Kabel, 1x lang, 1x kurz

Signalgenerator Agilent 81110A, Inv.Nr.: 541-054, 3000EUR

DAQ:

Chrisu-PC, Inv.Nr.: 401-925

-- Monitore

---- Belinea, Inv.Nr.: 401-696

---- Gericom, SN.: M1132GR5467345

-- Keyboard & Maus

Wiener 9U-VME-Crate, Inv.Nr.: 545-043, 3000EUR

-- Power Supply

-- VME-Controller

-- 4 VME-Module (1x Buffer, 3x FADC)

DOCK-Box

-- Power Kabel

VME-Kabel (bockig) + Verlaengerung

30m-Kabel (8xCat7, 2xCat5, 2xgrau)

Lemo-Kabel

100pin-Flachkabel Neco-Buffer

Bananenkabel

Hybridkabel (8x SiLC, Belle-Kabel)

Special TLU-Adapter (flipping pin order of RJ45)

Schrauben für Crate-Montage

Erdungskabel (liegen am CERN im Labor)

THRX + Hum. Sensoren!

Magic Box

DUT:

Schrauben für Montage am Drehteller

4mm Steckschlauch Stickstoff (Laenge?)

Anschluss 1/8" auf 4mm Steckschlauch

Druckminderer, SN.: 717.06143

-- 6mm Snap-In

-- 6mm Schlauch

Chiller Huber ministat 230, Inv.Nr.: 482-021, 4000EUR

-- Manual

-- Netzteil

-- langes serielles Kabel

-- 5-6mm Schlauch

-- Adapter

-- 5 Liter dest. Wasser (falls noch Platz ist)

-- LabView (falls ferngesteuert)

Box-Deckel

Baseplates (4?)

Gaffa

Doppelscotch

Schwarze Selbstklebefolie

Alufolie

Sockel (2 verschiedene)

Schablonen für SiLC-Angle Scan (08-Modules)

gscheites Verlängerungskabel

genug Schrauben, Gewindestangen, Flügelmuttern

2 Balken für Pt-Module Drehungen (+ genug "Bolzen")

GROSSES SCHWARZES LICHTDICHTES TUCH !!!!

THRX-Kabel & Sensoren

25 Module

-- 4 Belle-Module (1 Stack)

-- 2 pt-Module

-- 2 Alignment-Module

-- 2 Stacks mit Warschau-Sensoren (1x 6 Sensoren, 1x 3 Sensoren)

-- 8 SiLC-Module (1 Stack)

EDV:

Netzwerkkabel

Netzwerk-Switch:

-- 3com Gigabit Switch 8, SN.: AB/9XRQ9J00171B0

-- D-Link 8-Port GBit-Switch

WLAN-Router: Linksys WRT54GL-DE, SN.: CL7B1H502248, 60 EUR

1TB externe Festplatte: Western Digital MyBook, SN.: WCA551469094

-- Netzgeraet

-- USB-Kabel

-- Firewire 400/800 Kabel

Webcam

USB-Stick

Etikettiergeraet: Brother P-touch 1000

Verlaengerungskabel ohne Ende…

1 Dose Druckluft zur Reinigung

Laptops

-- Apple MacBook (MV) Inv.Nr.: 401-810

-- Apple MacBook Pro (MD) Inv Nr.: 401-831

-- Apple MacBook (GA) SN.:W87411Q3Z5Z

2x PCI Express-Karten (noch zu kaufen), je 30EUR

2x USB-Seriell Adapter

1 Trommel Ethernet-Kabel (100m, vom Walzel)

einige RJ-45 Stecker

2.5" externe HD

CD und DVD Rohlinge

Tools:

Diverse Adaptoren Lemo-BNC, Lemo-Lemo

Taschenlampe + 2x Hirnbirn

Massband

Multimeter

Werkzeug (Schraubenzieher & Co)

Pinzetten

Laserpointer

Schwarze Fetzen

Scotch tape

Kabelbinder

Adapter f. Steckdosen

Verteiler-Leisten

Tixo klein & gross

Loetstation Advanced JBC, SN.: 76841165, inkl. Zubehoer

Ethernet-Crimp-Zange

Eisensagl

Schublehre

Misc:

Fondueset

Spiegelreflex Digitalkamera Canon 450D (400EUR)

-- Stativ

-- Reflexionszelt

SLR Marko

Stativ

Scheinwerfer (fuer ordentliche Fotos)

Akkus+Ladegerät

Dickes Logbook

Kugelschreiber/Bleistifte

Pflaster

Carnet ATA |

| Attachment 1: carnet_aug09.xls

|

|

10

|

Fri Jul 17 14:03:21 2009 |

Stephan Hänsel | | What to measure | | | | |

Origami

Testbeam08 Module

- Anglescan

Pt Modules (2Stück - je 2 Sensoren):

Anglescan

- einzelne module (auch als "stub" (fixer Abstand zwischen ihnen) ?)

wichtig: brauchen wir 2 Testbeam08 module um 90° verdreht für höheninformation??? (sensoren in den Pt-modulen sind nicht 100%ig parallel - MESSEN!)

Optical Modules:(DAUER ca 18 Stunden)

- tests in box mit laserbeam (laser auf anderer Höhe al beam?!? - sonst geht der beam durch den Laser)

ITE Modules:

- 8 ter stack: (2 Testbeam08 module quer + 2 x 1stmetal128 + 2 x 2nd metal 128 + 2 x normal128)

- 2ndmetal512 module 3 stück bauen und im beam versetzt einbauen parasitär bei den spanier-modulen)

zusätliche ideen:

- CMS-Tracker slice (2Pt + 2 optische + 3 2ndmetal512 hintereinander in unterschiedlichen winkeln um einen tracker-slice zu simulieren - CMS-layout !?!)

|

|

11

|

Fri Jul 31 19:23:26 2009 |

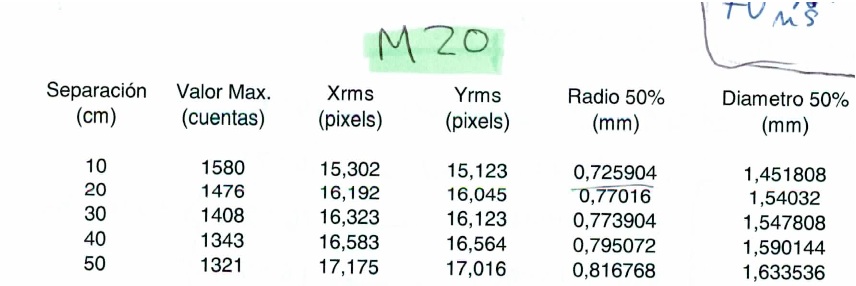

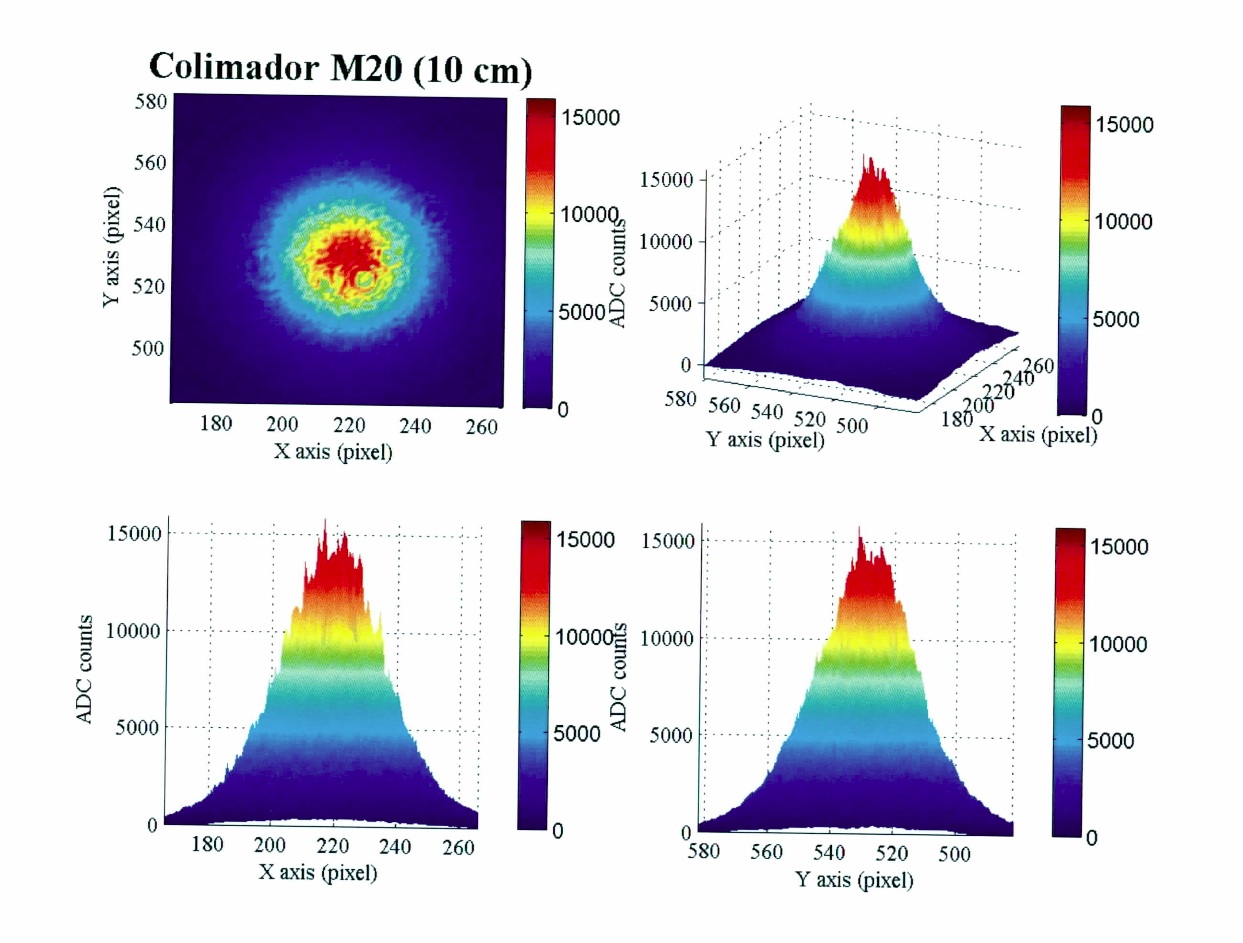

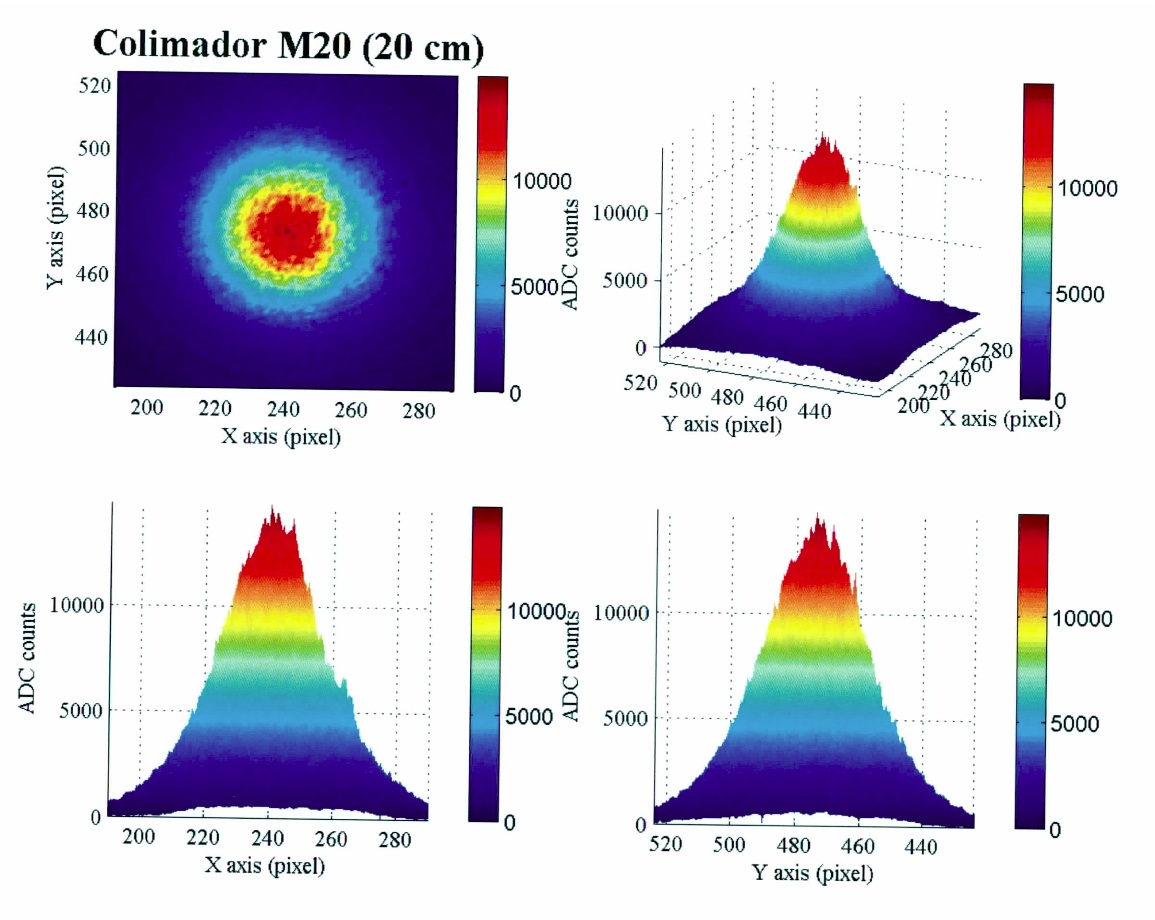

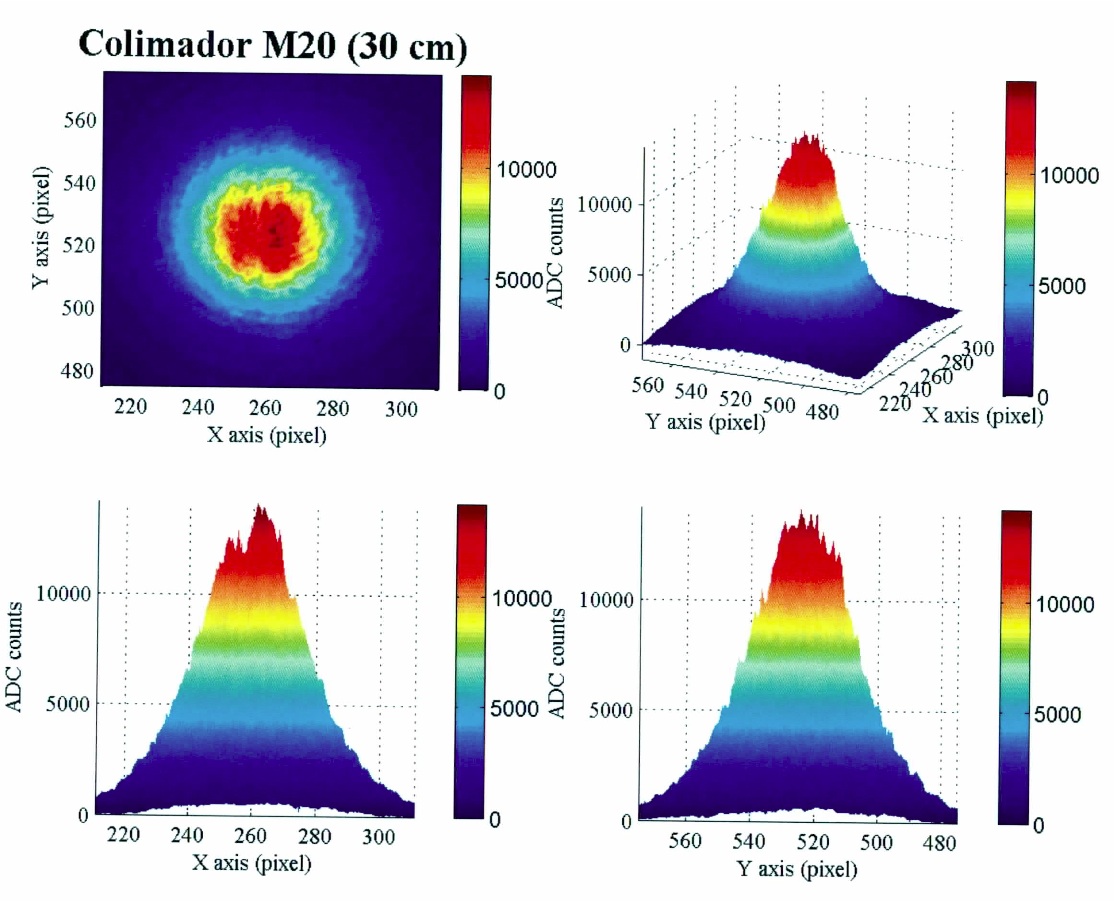

Thomas Bergauer | | Laser Spot size | | | | |

| 10cm nach Kollimator: Durchmesser 1.45mm (FWHM)

20cm nach Kollimator: Durchmesser 1,54mm (FWHM) |

| Attachment 1: laser_spot_overview.jpg

|

|

| Attachment 2: laser_spot_10cm.jpg

|

|

| Attachment 3: laser_spot_20cm.jpg

|

|

| Attachment 4: laser_spot_30cm.jpg

|

|

|

12

|

Tue Aug 11 14:03:57 2009 |

Marko Dragicevic | | Sensor Designs | | | | |

Screenshots

HEPHY Gallery

GDS File Viewer

KLayout Website

Layer Properties File Warsaw.lyp in den Attachments. |

| Attachment 1: Wafer.gds

|

| Attachment 2: SensorSTD.gds

|

| Attachment 3: SensorPAS.gds

|

| Attachment 4: SensorPAD.gds

|

| Attachment 5: Sensor512.gds

|

| Attachment 6: Warsaw.lyp

|

<?xml version="1.0"?>

<layer-properties>

<properties>

<frame-color>#01ff6b</frame-color>

<fill-color>#01ff6b</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I3</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>NPlus</name>

<source>1/0@1</source>

</properties>

<properties>

<frame-color>#ff0000</frame-color>

<fill-color>#ff0000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I9</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PPlus</name>

<source>2/0@1</source>

</properties>

<properties>

<frame-color>#ff8000</frame-color>

<fill-color>#ff8000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Via</name>

<source>3/0@1</source>

</properties>

<properties>

<frame-color>#00ffff</frame-color>

<fill-color>#00ffff</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I15</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Metal</name>

<source>4/0@1</source>

</properties>

<properties>

<frame-color>#ff00ff</frame-color>

<fill-color>#ff00ff</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I2</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Passivation</name>

<source>5/0@1</source>

</properties>

<properties>

<frame-color>#91ff00</frame-color>

<fill-color>#91ff00</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I3</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PolySilicon</name>

<source>6/0@1</source>

</properties>

<properties>

<frame-color>#008050</frame-color>

<fill-color>#008050</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I2</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PolySiHeads</name>

<source>7/0@1</source>

</properties>

<properties>

<frame-color>#ffa080</frame-color>

<fill-color>#ffa080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Via2</name>

<source>8/0@1</source>

</properties>

<properties>

<frame-color>#000080</frame-color>

<fill-color>#000080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I12</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Metal2</name>

<source>10/0@1</source>

</properties>

<properties>

<frame-color>#ffa080</frame-color>

<fill-color>#ffa080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I1</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Margins</name>

<source>11/0@1</source>

</properties>

<properties>

<frame-color>#805000</frame-color>

<fill-color>#805000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Dicing Lines</name>

<source>12/0@1</source>

</properties>

<custom-dither-pattern>

<pattern>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

</pattern>

<order>1</order>

<name></name>

</custom-dither-pattern>

</layer-properties>

|

|

13

|

Fri Aug 14 16:45:25 2009 |

Stephan Hänsel | | Module - Setups | | | | |

- 5mm Inbus-Schlüssel

- 3mm Inbus Schlüssel

- 6- 2(1) x 30 Pt-Pins

- beim 5mm-Sockel müssen die 2 Löcher über die das optische Modul h03 verschraubt wird noch ausgeweitet werden (Thomas)

- bei Pt-Deckel oben einzeichnen welche Balkenstellung welchem Winkel entspricht

(SK) ... SenkKopf

(ZK) ... ZylinderKopf

OPTISCHER SETUP - Setup-alignment-modules

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) Collimator

- Alu-Spacer (neuer = höheren verwenden) + 4- M6 x 15 (ZK)

- schwarzer-Spanier-x-y-z-Tisch - Schreuben dabei -> Plastikschrauben abschneiden ?!?

2) 5mm Spacer + h03 - backplane richtung Collimator - APV3210

- 2- M4 x 15 (SK) - 5mm Spacer durch Alignment-Boden mit h03 verschrauben

- 3- M4 x 15 (SK) - Alignment-Boden auf Drehteller verschrauben

3) h04 - backplane richtung Collimator - APV3210

- 2 Positionen

- 2- M4 x 10 (SK)

Pt + ITE-512-Stack + 3 SiLC08-Module

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h06-ITE-512 - APV0123 (allerdings nur eineinhalb APVs gebondet!)

2) h05-ITE-512 - APV0123

3) h07-ITE-512 - APV3210 !!!

4) SiLC08-2 - APV12 - 90° gedreht

5) SiLC08-1 - APV12 - 90° gedreht

6) SiLC08-0 - APV12 - 90° gedreht

Stack 1) bis 6)

- schwarzer Sockel +4- M4 x 35 (ZK) -> verschraubt in h06 und h07

- 2 Gewindestangen M6 x 80 + 4 Scheiben + 4 Muttern M6 -> die 3 ITE-512er zusammen

- 3 Gewindestangen M6 x 160 + 6 Scheiben + 5 Flügelmuttern M6 + 1 Mutter M6 -> 3- SiLC08-Module VORSICHTIG dazu

7) h02-Pt - APV0123 - überprüfen - kann rotieren ;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

8) h01-Pt - APV0123 - überprüfen - kann rotieren;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

ITE128-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h21_alignment-TS05 - APV12 - 90°gedreht

2) h13_ITE-PAS - APV1

3) h14_ITE-PAS - APV1

4) h15_ITE-PAD - APV1

5) h16_ITE-PAD - APV1

6) h11_ITE-STD - APV1

7) h12_ITE-STD - APV1

8) h22-alignment-TS07 - APV12 - 90°gedreht

Schrauben verwenden je nach Sockel und Spacer

SiLC08-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) SiLC08-7 - APV12 - Überprüfen

2) SiLC08-6 - APV12 - Überprüfen

3) SiLC08-5 - APV12 - Überprüfen

4) SiLC08-4 - APV12 - Überprüfen

5) SiLC08-3 - APV12 - Überprüfen

6) SiLC08-2 - APV12 - Überprüfen

7) SiLC08-1 - APV12 - Überprüfen

8) SiLC08-0 - APV12 - Überprüfen

Schrauben verwenden je nach Sockel und Spacer |