| ID |

Date |

Author |

Project |

Subject |

Run Number |

Events |

StartTime |

EndTime |

|

12

|

Tue Aug 11 14:03:57 2009 |

Marko Dragicevic | | Sensor Designs | | | | |

Screenshots

HEPHY Gallery

GDS File Viewer

KLayout Website

Layer Properties File Warsaw.lyp in den Attachments. |

| Attachment 1: Wafer.gds

|

| Attachment 2: SensorSTD.gds

|

| Attachment 3: SensorPAS.gds

|

| Attachment 4: SensorPAD.gds

|

| Attachment 5: Sensor512.gds

|

| Attachment 6: Warsaw.lyp

|

<?xml version="1.0"?>

<layer-properties>

<properties>

<frame-color>#01ff6b</frame-color>

<fill-color>#01ff6b</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I3</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>NPlus</name>

<source>1/0@1</source>

</properties>

<properties>

<frame-color>#ff0000</frame-color>

<fill-color>#ff0000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I9</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PPlus</name>

<source>2/0@1</source>

</properties>

<properties>

<frame-color>#ff8000</frame-color>

<fill-color>#ff8000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Via</name>

<source>3/0@1</source>

</properties>

<properties>

<frame-color>#00ffff</frame-color>

<fill-color>#00ffff</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I15</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Metal</name>

<source>4/0@1</source>

</properties>

<properties>

<frame-color>#ff00ff</frame-color>

<fill-color>#ff00ff</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I2</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Passivation</name>

<source>5/0@1</source>

</properties>

<properties>

<frame-color>#91ff00</frame-color>

<fill-color>#91ff00</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I3</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PolySilicon</name>

<source>6/0@1</source>

</properties>

<properties>

<frame-color>#008050</frame-color>

<fill-color>#008050</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I2</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PolySiHeads</name>

<source>7/0@1</source>

</properties>

<properties>

<frame-color>#ffa080</frame-color>

<fill-color>#ffa080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Via2</name>

<source>8/0@1</source>

</properties>

<properties>

<frame-color>#000080</frame-color>

<fill-color>#000080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I12</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Metal2</name>

<source>10/0@1</source>

</properties>

<properties>

<frame-color>#ffa080</frame-color>

<fill-color>#ffa080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I1</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Margins</name>

<source>11/0@1</source>

</properties>

<properties>

<frame-color>#805000</frame-color>

<fill-color>#805000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Dicing Lines</name>

<source>12/0@1</source>

</properties>

<custom-dither-pattern>

<pattern>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

</pattern>

<order>1</order>

<name></name>

</custom-dither-pattern>

</layer-properties>

|

|

13

|

Fri Aug 14 16:45:25 2009 |

Stephan H�nsel | | Module - Setups | | | | |

- 5mm Inbus-Schlüssel

- 3mm Inbus Schlüssel

- 6- 2(1) x 30 Pt-Pins

- beim 5mm-Sockel müssen die 2 Löcher über die das optische Modul h03 verschraubt wird noch ausgeweitet werden (Thomas)

- bei Pt-Deckel oben einzeichnen welche Balkenstellung welchem Winkel entspricht

(SK) ... SenkKopf

(ZK) ... ZylinderKopf

OPTISCHER SETUP - Setup-alignment-modules

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) Collimator

- Alu-Spacer (neuer = höheren verwenden) + 4- M6 x 15 (ZK)

- schwarzer-Spanier-x-y-z-Tisch - Schreuben dabei -> Plastikschrauben abschneiden ?!?

2) 5mm Spacer + h03 - backplane richtung Collimator - APV3210

- 2- M4 x 15 (SK) - 5mm Spacer durch Alignment-Boden mit h03 verschrauben

- 3- M4 x 15 (SK) - Alignment-Boden auf Drehteller verschrauben

3) h04 - backplane richtung Collimator - APV3210

- 2 Positionen

- 2- M4 x 10 (SK)

Pt + ITE-512-Stack + 3 SiLC08-Module

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h06-ITE-512 - APV0123 (allerdings nur eineinhalb APVs gebondet!)

2) h05-ITE-512 - APV0123

3) h07-ITE-512 - APV3210 !!!

4) SiLC08-2 - APV12 - 90° gedreht

5) SiLC08-1 - APV12 - 90° gedreht

6) SiLC08-0 - APV12 - 90° gedreht

Stack 1) bis 6)

- schwarzer Sockel +4- M4 x 35 (ZK) -> verschraubt in h06 und h07

- 2 Gewindestangen M6 x 80 + 4 Scheiben + 4 Muttern M6 -> die 3 ITE-512er zusammen

- 3 Gewindestangen M6 x 160 + 6 Scheiben + 5 Flügelmuttern M6 + 1 Mutter M6 -> 3- SiLC08-Module VORSICHTIG dazu

7) h02-Pt - APV0123 - überprüfen - kann rotieren ;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

8) h01-Pt - APV0123 - überprüfen - kann rotieren;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

ITE128-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h21_alignment-TS05 - APV12 - 90°gedreht

2) h13_ITE-PAS - APV1

3) h14_ITE-PAS - APV1

4) h15_ITE-PAD - APV1

5) h16_ITE-PAD - APV1

6) h11_ITE-STD - APV1

7) h12_ITE-STD - APV1

8) h22-alignment-TS07 - APV12 - 90°gedreht

Schrauben verwenden je nach Sockel und Spacer

SiLC08-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) SiLC08-7 - APV12 - Überprüfen

2) SiLC08-6 - APV12 - Überprüfen

3) SiLC08-5 - APV12 - Überprüfen

4) SiLC08-4 - APV12 - Überprüfen

5) SiLC08-3 - APV12 - Überprüfen

6) SiLC08-2 - APV12 - Überprüfen

7) SiLC08-1 - APV12 - Überprüfen

8) SiLC08-0 - APV12 - Überprüfen

Schrauben verwenden je nach Sockel und Spacer |

|

14

|

Fri Aug 14 19:35:43 2009 |

Thomas Bergauer | Pt_ITE512 | intcal | | | | |

HV=100V except h05-ITE-512 and h06-ITE-512 (runaway, HV off)

h01-Pt: 10uA

h02-Pt: 1.6uA

3 SiLC DUTs mit je ca. 38nA

h07-ITE-512: 3.77uA

h05-ITE-512: breakthrough

h06-ITE-512: breakthrough |

|

15

|

Fri Aug 14 21:36:17 2009 |

Markus Friedl | | Config files | | | | |

Status of config files as of Friday 14 August 2009 late evening

| Config file name |

Timing adjusted |

Sensor definition |

Tested |

| cern09_ite128_single1 |

YES |

NOT YET (?) |

YES |

|

cern09_ite128_multi6

|

YES |

NOT YET (?) |

YES |

|

cern09_pt_ite512_single1

|

YES |

NOT YET (?) |

YES |

|

cern09_pt_ite512_multi6

|

YES |

NOT YET (?) |

NO |

|

cern09_alignment_beam_single1

|

YES |

NOT YET (?) |

YES |

|

cern09_alignment_beam_multi6

|

YES |

NOT YET (?) |

YES |

|

cern09_belle_single

|

YES |

NOT YET (?) |

YES |

|

cern09_belle_multi6

|

YES |

NOT YET (?) |

YES |

| cern09_silc_all_single |

YES (2008) |

YES (2008) |

NO |

| cern09_silc_all_multi6 |

YES (2008) |

YES (2008) |

NO |

|

|

16

|

Wed Aug 19 15:37:37 2009 |

Christian Irmler | ITE128 | internal calibration | cal001 | | 15:31:29 | |

8 modules, HV=70V, 40MHz, 1 sample

no beam

APV 4,5: inverter off, higher baseline = PAD modules |

|

17

|

Wed Aug 19 15:41:17 2009 |

Wolfgang Kiesenhofer | SiLC | angle scan templates | | | | |

Linie am rechten Seitenrand (in der Vorschau unten leider nicht gut zu sehen) sollte mit dem rechten Rand der Basisplatte abschließen (bezogen auf die Beam Richtung). |

| Attachment 1: angle_scan0.pdf

|

| Attachment 2: angle_scan5.pdf

|

| Attachment 3: angle_scan10.pdf

|

| Attachment 4: angle_scan15.pdf

|

| Attachment 5: angle_scan20.pdf

|

| Attachment 6: angle_scan25.pdf

|

| Attachment 7: angle_scan30.pdf

|

| Attachment 8: angle_scan35.pdf

|

| Attachment 9: angle_scan40.pdf

|

| Attachment 10: angle_scan45.pdf

|

| Attachment 11: angle_scan50.pdf

|

| Attachment 12: angle_scan55.pdf

|

| Attachment 13: angle_scan60.pdf

|

|

20

|

Wed Aug 19 22:57:13 2009 |

Marko Dragicevic | | How-To | | | | |

TLU (run from DAQPCHEPHY):

ssh eudet@eudetmac001.cern.ch

ssh tlupc

~\eudaq\bin\TLUControl.exe -d1 -a12

-t100 internal trigger

-aXX Mask for Szintis:

1 4 mm (front)

2 4 mm (front)

4 9 mm (back)

8 9 mm (back)

DAQ:

Hostname: DAQPCHEPHY.CERN.CH

XY Table PC:

Hostname: XYPCEUDET.CERN.CH

Beam Control:

Hostname: cwo-hna453-h6b1.cern.ch

137.138.61.206

Eudet DAQ:

vnc eudetmac001.cern.ch

Cycle Run:

o) stop DAQ

o) kill eudaq Run Control

o) restart: ./STARTRUN.FORTIS.1

o) load config: testfortis_with_eudrb_beam_backpressure_WITH_SILC

o) press: Config (wait ~1 min.)

o) press: Start |

|

22

|

Thu Aug 20 00:31:45 2009 |

Christian Irmler | ITE128 | ITE128 shooting into strips w pitch adapter, upper position | run003 | 100600 | 20.08.2009 00:27:36 | |

DUT: SiLC 08_1, 6 x ITE128, SiLC 08_2

HV = 70V, 40MHz, 120 GeV

TLU trigger, w/o telescope

9x9 mm beam spot

height (y) = 139.3100

ITE128 shooting into strips w pitch adapter, upper edge of sensor |

|

33

|

Thu Aug 20 15:54:45 2009 |

Manfred Valentan | BELLE | temp/humidty logger data | | | | |

position: underneath telescope. dewpoint ~ 15 degree

test with chiller: running 4 hours at 15 degress: NO condensation on alu pipe |

| Attachment 1: easylog_under_telescope.gif

|

|

|

34

|

Thu Aug 20 18:56:25 2009 |

Christian Irmler | alignment_laser | laser | laser001 | 100000 | 20.08.2009 18:48:53 | |

2 alignment modules

location in beam direction: h04-h03

laser is shooting on h03 (opposite to the beam)

HV=70V, 40MHz, 6 samples

beam off

module 1 (h03) is used w inverter off

since the signal off the second sensor is only 10 percent, the base line of h03 was increased again (now @ 260 ADC).

5ns trigger pulse width, 1 kHz trigger,

current_laser=10mA,

Photodiode: pulse_width=15ns, amplitude=7mV

bad strips: APV5: 115, APV6: 1 |

|

51

|

Fri Aug 21 13:38:20 2009 |

Christian Irmler | BELLE | APVDAQ standalone 31.8 MHz hit mode | run011 | 75000 | 21.08.2009 13:35:25 | |

4 Belle DUTs

HV=80V, 31.8 MHz, 6 sample, 120 GeV

external clock source

processed mode, hit cut = 5

beam position: p-side: APV2 of Origami, n-side: between APV1 and 2 of Origami (center of sensors)

JP-module is hit at APV3, module seems to be on a higher position than in past beam test (eventuelly flipped) |

|

54

|

Fri Aug 21 16:37:22 2009 |

Christian Irmler | BELLE | internal calibration 40 MHz hit mode | cal006 | | 21.08.2009 16:30:33 | |

Belle DUT, intcal

HV=80V, 40 MHz, no beam

hit mode

switched back to internal 40 MHz clock |

|

55

|

Fri Aug 21 17:14:58 2009 |

Wolfgang Kiesenhofer | | S/N Histograms Raw (no data selection) | run001 (strips), run002 (pitch adapter), run003 (upper edge) | | | |

|

| Attachment 1: sn_langaufit_raw_strips.pdf

|

| Attachment 2: sn_langaufit_raw_pa.pdf

|

| Attachment 3: sn_langaufit_raw_edgerun.pdf

|

|

58

|

Fri Aug 21 22:42:32 2009 |

Thomas Bergauer | common | EUDAQ config file used when running with telescope | | | | |

Used until Friday, 21.08.09:

AndMask = 0xf # 4x4 mm scintillator for trigger

Used since Friday, 21.08.09:

AndMask = 0xc # 9x9 mm scintillator for trigger

Local trigger using TLU only: ALWAYS WITH 9x9mm scintillator

|

| Attachment 1: testfortis_with_eudrb_beam_backpressure_WITH_SILC.conf

|

[RunControl]

RunSizeLimit = 1800000000

NoTrigWarnTime = 10

[DataCollector]

[LogCollector]

SaveLevel = EXTRA

PrintLevel = INFO

[Producer.TLU]

AndMask = 0xc # 9x9 mm scintillaotr for trigger

#AndMask = 0xf # 4x4 mm scintillator for trigger

OrMask = 0

VetoMask = 0

# EUDRB plugged into DUT#4 , FORTIS plugged into DUT#1, SiLC plugged into DUT#0

#DutMask = 20 # EUDRB, FORTIS, SiLC in

DutMask = 17 # FORTIS, SiLC in

EnableDUTVeto = 2#0

TriggerInterval = 0

TrigRollover = 0

StrobePeriod = 16000000

StrobeWidth = 480000

[Producer.EUDRB]

Version = 2

Det = MIMOTEL

Mode = ZS

Unsynchronized = 1

AdcDelay = 3

ClkSelect = 2

#Marker1 = 0xff

#Marker2 = 0xff

PostDetResetDelay = 4

PedestalFile = auto

IDOffset = 0

NumBoards = 6

Board0.Slot = 3

Board1.Slot = 5

Board2.Slot = 7

Board3.Slot = 9

Board4.Slot = 11

Board5.Slot = 13

[Producer.FORTIS]

# Need \ not / for directory name with Cygwin...

# ExecutableDirectory = /home/cussans/optodaq/halsall_test_v5/

ExecutableDirectory = /home/cussans/optodaq/MyF11/

# ExecutableDirectory = /home/cussans/optodaq/MyF10/

ExecutableProcessName = optodaqV.exe

#ExecutableFilename = test_run_128_block_mod_C2.bat

ExecutableFilename = test_run_512_128_block_mod_CX.bat

# ExecutableFilename = test_run_512_448_block_mod_full.bat

ExecutableArgs =

NumRows = 512

NumColumns = 128

|

|

65

|

Sat Aug 22 11:54:49 2009 |

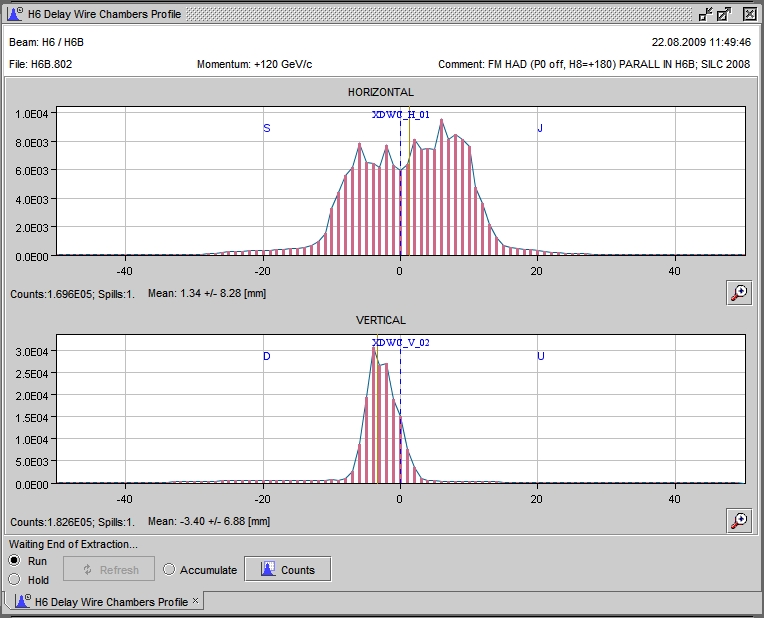

Thomas Bergauer | common | beam profile | | | | |

beam shifted a bit in vertical direction downwards since 21. August 09 evening

Beam configuration:

Beam configuration file: H6b.802 (FM HAD (P0 off, H8=+180) PARLALLEL IN H6B SILC 2008 |

| Attachment 1: 20090822_1150_beam_conditions.jpg

|

|

|

67

|

Sat Aug 22 13:28:53 2009 |

Wolfgang Kiesenhofer | Pt_ITE512 | runlist for pt-module angle-scan | | | | |

Preliminary run list for pt-modules + ite512 + silc1, silc2, silc5, silc6

| run |

angle[deg] |

pos |

height (xy-table) |

importance |

events |

| 1 |

1 |

center module |

|

+ |

10k |

| 2 |

2 |

center module |

|

+ |

10k |

| 3 |

3 |

center module |

|

+ |

10k |

| 4 |

4 |

center module |

|

+ |

10k |

| 5 |

5 |

center module |

|

+ |

10k |

| 6 |

6 |

center module |

|

+ |

10k |

| 7 |

7 |

center module |

|

+ |

10k |

| 8 |

8 |

center module |

|

+ |

10k |

| 9 |

9 |

center module |

|

+ |

10k |

| 10 |

10 |

center module |

|

+ |

10k |

| 11 |

12 |

center module |

|

+ |

10k |

| 12 |

14 |

center module |

|

- |

10k |

| 13 |

16 |

center module |

|

- |

10k |

| 14 |

0 |

center module |

|

+ |

? depends on ite512 |

| 15 |

0 |

upper pos |

|

+ |

10k |

| 16 |

0 |

lower pos |

|

+ |

10k |

|

|

71

|

Sat Aug 22 15:12:44 2009 |

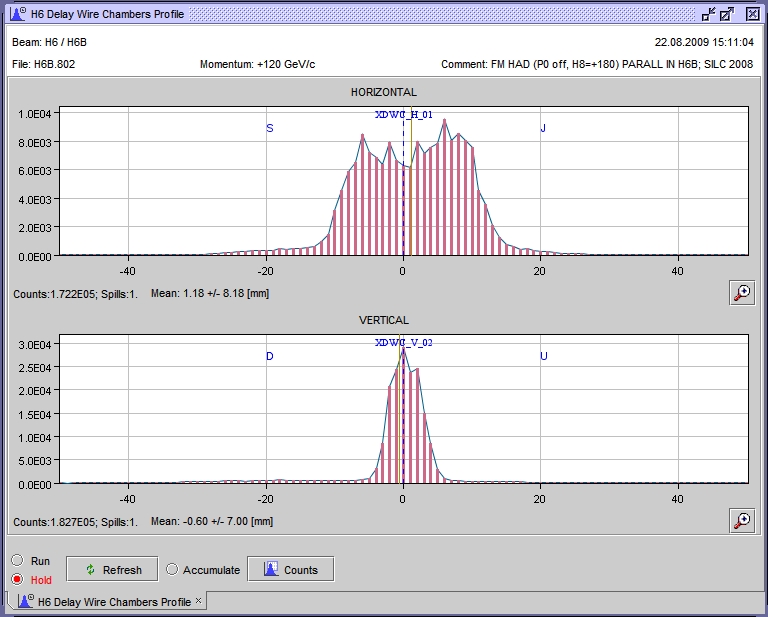

Thomas Bergauer | common | beam profile | | | | |

playing with TRIM4 in vertical plane (setting to 20A current) shifted beamspot back to center position

Beam configuration:

Beam configuration file: H6b.802 (FM HAD (P0 off, H8=+180) PARLALLEL IN H6B SILC 2008

Rate: 3.35E5 particles/spill (measured with SCINT8 in beamline)

Particle Production Applet

Calculator applet

For +120 Gev/c beam:

| Pi+ |

55.67 % |

| p |

38.95 % |

| K+ |

5.38 % |

|

| Attachment 1: 20090822_1511_beam_conditions.jpg

|

|

|

75

|

Sat Aug 22 22:14:50 2009 |

Christian Irmler | BELLE | internal calibration 40 MHz transparent mode + cooling | cal010 | | 22.08.2009 22:24:22 | |

Belle DUT, intcal

HV=80V, 40 MHz, beam off

1 sample, transparent mode

external clock

cooling

chiller set to 13 deg.

Bypass removed to achieve better watter flow at the module!

Chiller pump is set to 2800 rpm |

|

80

|

Sun Aug 23 13:15:42 2009 |

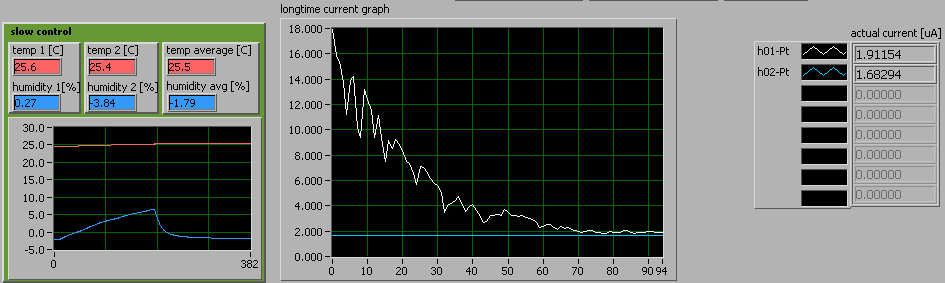

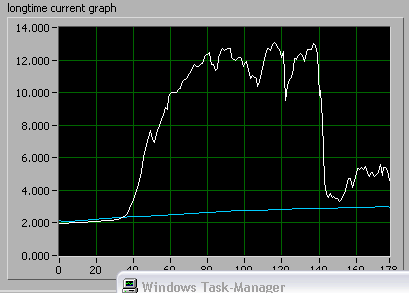

Marko Dragicevic | Pt_ITE512 | Current and Humindity during first Run | | | | |

Current of Pt modules during first run

Data of the run was dicarded.

Compressed air flow was at ~2 bars during run. Graph shows RH rise after switching of CA flow. Restarted at around 7% with very low pressure.

Timescales for RH and I graph are different!!!

after 3 hours first bottle of compressed air (dewpoint -170 degree C) is gone and sensor Pt-h01 starts to fluctuate again

Current of ITE512 plus 2 SiLC08 modules

HV=70V, Current: 25uA first, 29uA then, 35uA latest. now stable

|

| Attachment 1: IandRH_first_Pt_run.png

|

|

| Attachment 2: Picture_1.png

|

|

|

81

|

Sun Aug 23 14:03:14 2009 |

Manfred Valentan | Pt_ITE512 | Pt & ITE512 center position, 1 deg | run024 | 20000 | 23.08.2009 13:59:06 | |

Pt: 1 Grad, HV=200V, 0% RH

ITE512: HV=70V

X-Y-Table: x=99.6, y=36

Telescope: run7316 |