| ID |

Date |

Author |

Type |

Subject |

|

1

|

Wed Oct 1 11:42:44 2008 |

stephan hänsel | Setup | Modulkomponenten |

MODULE 0

1 Sensor Module (SiLC01):

Hybrid: TEC_6D.2.1 / 30216662133923

Sensor: HPK-ILC-6684-01

2 Sensor Module (SiLC02):

Hybrid: TEC_6D.2.1 / 30216662133993

Sensor Near: HPK-ILC-6684-19

Sensor Far: HPK-ILC-6684-05

MODULE 1

1 Sensor Module (SiLC11b):

Hybrid: TEC_6D.2.1 / 30216662133904

Sensor: HPK-ILC-6684-23

2 Sensor Module (SiLC12):

Hybrid: TEC_6D.2.1 / 30216661605173

Sensor Near: HPK-ILC-6684-34

Sensor Far: HPK-ILC-6684-27

(OLD - 1 Sensor Module (SiLC11):

Hybrid: TEC_6D.2.1 / 30216662133922

Sensor: HPK-ILC-6684-23)

|

|

2

|

Wed Feb 25 09:57:15 2009 |

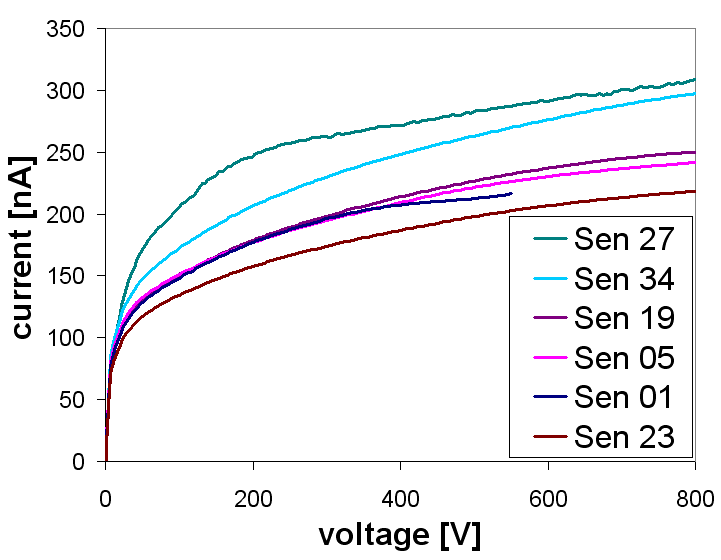

Stephan Hänsel | Measurements | Sensor IV-Kurven + CV-Messungen (vor Modulbau) |

| Object ID |

Vdepl |

I bei 300V |

I bei 450V |

| ILC-6684-01 |

53 |

1,96E-07 |

2,10E-07 |

| ILC-6684-05 |

53 |

1,95E-07 |

2,16E-07 |

| ILC-6684-19 |

50 |

1,98E-07 |

2,21E-07 |

| ILC-6684-23 |

50 |

1,74E-07 |

1,93E-07 |

| ILC-6684-27 |

55 |

2,62E-07 |

2,77E-07 |

| ILC-6684-34 |

58 |

2,30E-07 |

2,56E-07 |

|

| Attachment 1: IV-Kurven_Sensors.png

|

|

|

3

|

Fri Feb 27 13:34:11 2009 |

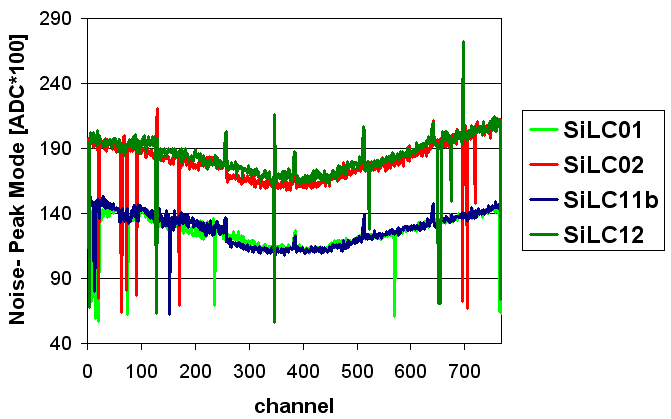

Stephan Hänsel | Measurements | ARCs Noise PIoff + channels 2 repair |

|

Noise Peak Inverter Off

(SiLC11b after repair --- b ... 2nd module with same sensors but different hybrid and PA)

|

| |

|

|

|

|

| |

Noise Pioff [ADC*100] |

optical inspection |

Noise Pioff [ADC*100] |

|

| |

1ADC-count entspricht ca 770 e- |

|

1ADC-count entspricht ca 770 e- |

|

| CHANNEL |

SiLC01 |

After Repair |

Measurement 06 |

CCU123-16 back Z

repair-action

|

| 5 |

64 |

|

142 |

non |

| 6 |

65 |

|

142 |

non |

| 7 |

80 |

|

135 |

non |

| 8 |

135 |

good |

72 |

PA-PA rebond |

| 9 |

80 |

|

133 |

non |

| 10 |

139 |

good |

77 |

PA-PA rebond |

| 12 |

139 |

good |

76 |

PA-PA rebond |

| 15 |

73 |

|

59 |

PA-PA rebond |

| 21 |

145 |

good |

57 |

PA-PA rebond |

| 73 |

77 |

|

134 |

non |

| 74 |

70 |

|

135 |

non |

| 75 |

137 |

good |

62 |

? PA-PA rebond |

| 137 |

76 |

|

137 |

non |

| 236 |

76 |

|

69 |

? PA-PA rebond |

| 281 |

55 |

|

126 |

non |

| 453 |

67 |

|

118 |

non |

| 570 |

63 |

|

61 |

Jakkoo-PA Open |

| 666 |

64 |

|

134 |

non |

| 668 |

62 |

|

136 |

non |

| 715 |

74 |

|

144 |

non |

| 764 |

67 |

|

134 |

non |

| 765 |

141 |

good |

66 |

PA-PA rebond |

| 766 |

145 |

good |

65 |

PA-PA rebond |

| 768 |

136 |

good |

63 |

PA-PA rebond |

| |

|

|

|

|

| |

|

|

|

|

| CHANNEL |

SiLC02 |

|

|

|

| 21 |

75 |

Jakkoo-PA Open |

|

CCU123-17 back X

|

| 63 |

64 |

PA-SE rebond |

|

|

| 73 |

81 |

? |

|

|

| 91 |

77 |

PA-PA rebond |

|

|

| 170 |

69 |

? |

|

|

| 696 |

72 |

PA-SE rebond |

|

|

| 704 |

67 |

PA-SE rebond |

|

|

| 719 |

148 |

SE-SE rebond |

|

|

| |

|

|

|

|

| |

|

|

|

|

| CHANNEL |

SiLC11b |

Measurement 06 |

|

CCU119-17 front Z

|

| 13 |

80 |

Jakkoo-PA Open |

|

|

| 153 |

62 |

Jakkoo-PA Open |

|

|

| 415 |

|

? Remove bond -> IV verbesserung |

|

|

| 713 |

|

? Remove bond -> IV verbesserung |

|

|

| |

|

|

|

|

| |

|

|

|

|

| CHANNEL |

SiLC12 |

Measurement 02 |

|

CCU119-16 front X

|

| 3 |

68 |

Jakkoo-PA Open |

|

|

| 128 |

63 |

? |

|

|

| 346 |

57 |

APV-PA Open |

|

|

| 523 |

128 |

? |

|

|

| 651 |

71 |

Jakkoo-PA Open |

|

|

| 652 |

72 |

Jakkoo-PA Open |

|

|

| 653 |

71 |

Jakkoo-PA Open |

|

|

| 654 |

71 |

Jakkoo-PA Open |

|

|

| 655 |

71 |

Jakkoo-PA Open |

|

|

| 675 |

149 |

? |

|

|

| 767 |

74 |

? Jakkoo-PA Open |

|

|

|

| Attachment 1: NoisePlot.png

|

|

|

4

|

Fri Feb 27 14:03:53 2009 |

Stephan Hänsel | Setup | Setup 3D |

|

| Attachment 1: 090227_TPCEnvelope-3D_copy.png

|

|

|

5

|

Thu Oct 22 08:02:26 2009 |

Stephan Hänsel | Setup | Electronics |

HV-Kapton-PIN-assignment

CCUM-to-Module Adapter-Cards

CCUM-to-Module Adapter-Cards Pin-assignment (xls)

schematic of the adopted readout (A.Dierlamm)

TEC-R2-Hybrid |

|

6

|

Thu Oct 22 08:04:51 2009 |

Stephan Hänsel | Setup | geometry - silicon envelope |

distance si-sledge-front to silicon-Z-center = 23 cm

-> silicon sledge front 35 cm inside from front of TPC-support at a beam position 58 cm from front of TPC-support

CCU119 = 0x77

- position 7 = I2C16 = SiLC12 -> front X

- position 1 = I2C17 = SiLC11 -> front Z

CCU123 = 0x7b

- position 7 = I2C16 = SiLC01 -> back Z

- position 1 = I2C17 = SiLC02 -> back X

|

| Attachment 1: SiLC_in_front_of_TPC.jpg

|

|

|

7

|

Thu Oct 22 11:18:34 2009 |

Stephan Hänsel | Setup | Pictures |

Photo Gallery

zusätliche Photos:

labeled SiLC in front of TPC |

|

8

|

Fri Oct 23 07:52:52 2009 |

Stephan Hänsel | Measurements | Run 11269 - Pedestal Run |

B=0, TPC inbetween but no TPC readout |

|

9

|

Fri Oct 23 07:57:01 2009 |

Stephan Hänsel | Measurements | Run 11270 - latency scan |

B=0, TPC inbetween but no TPC readout

scan from 70 to 120 with 1000 events each

root-diagram -> latency ~ 75

-> set apvlatency in fedpmc_silc.xml to 75 |

|

10

|

Fri Oct 23 08:02:57 2009 |

Stephan Hänsel | Measurements | Run 11271 - position run |

B=0, TPC inbetween but no TPC readout

Beam: 3GeV

moved silicon to center position (~58cm from TPC-support-ring)

2 APVs dead:

apvlatency = 75 (in fedpmc_silc.xml)

2-sensor-module in center

1-sensor-module not exactly in center-position:

12316 -> move out of the magnet 1,5cm

11917 -> move out of the magnet 1cm |

|

11

|

Fri Oct 23 08:09:04 2009 |

Stephan Hänsel | Measurements | Run 11273 - data |

B=0, TPC inbetween but no TPC readout

Beam: 3GeV

silicon position from TPC-support-ring:

123: x=center, z=56.5 cm (measuring tape: sledge 35cm inside the gap)

116: x=center, z=57 cm (measuring tape: sledge 35cm inside the gap)

2 APVs dead:

apvlatency = 75 (in fedpmc_silc.xml) |

|

12

|

Mon Nov 2 13:22:50 2009 |

Stephan Hänsel | Setup | DAQ |

start data-taking:

ssh xxx@bastion.desy.de -X

ssh xdaq@flctpcikhero1.desy.de -X

-

at PC reboot:

- source xdaq_profile

- cd scripts

- ./fedpmc 0 + ctrl C when ready //initialise the first FED

- ./fedpmc 1 + ctrl C when ready //initialise the second FED

- ./gatecalib //sets adresses for the TSC + gate

- ./setdll 3 5 //sets width of the gate

when controllring newly connected

- source xdaq_profile (if not done before)

- cd scripts

- ./ProgramTest.exe -pci -reset //-> controllring 0x4c90

test of devices:

- source xdaq_profile (if not done before)

- cd scripts

- ./ProgramTest.exe -pci -scanCCU // searches for CCUs

- ./ProgramTest.exe -pci -scantrackerdevice // searches for CCUs and APVs

start xdaq:

- source xdaq_profile (if not done before)

- /opt/firefox/firefox & -> http://ikhero2.desy.de:40000 // not working for now

- ./xdaq.sh -p40000

- reload firefox

HyperDAQ:

- -> Control Panel -> Configure Cluster -> load /home/xdaq/xml/peak_silc.xml

- tick: Configure Cluster

- -> submit

- -> view Applications -> Tracker Supervisor:

- choose run type -> normal

- tick: TLU in physics Run

- type spillsize = 20

- tick: No gate

if xdaq kills itself:

analysis:

- root:

- in /Analysis/AC1Analysis-1.4>

- .L runAna_silc.C

- runAna(pedestalnumber,runnumber)

get file with number of single events in all 4 sensors + HitProfile

- root

- .L readClusterTree_silc.cxx++

- readClusterTree_silc(event number)

|

|

13

|

Mon Nov 2 13:59:09 2009 |

Stephan Hänsel | Setup | ToDo before data-taking |

in hut:

- plug twisted pair cable from CCUM into PC (Attention - connector contains more pins, look at marks - use the most right pins when you look from the back of the PC))

- power on CCUM in spacing behind electronic hut

- switch on opto-electrical converter for FED (on top of PC (switch in the back) and switch on power supply (front))

- LV on -> 01,30 and 02,60 (two times)

- HV on -> 200V

T24/1

- power the scintillators for triggering

- move envelope into beamline - sledge front to sensor center is 220,5mm

-> switch on the beam |

|

14

|

Tue Nov 3 10:45:01 2009 |

Stephan Hänsel | Setup | Beam On |

clear test beam areas:

go to T24 (front area):

- use (red) key from interlock

- go into T24 area, close door, use red key in keyhole next to door -> big red light on

- push the white buttons "Absuche" below the three red "Not Aus" (emergency stop) buttons

- go back to the door, turn key and keep it turned!

- open the door, move out and close it again behind you

- now it is the time to return the key again -> two green lights should go on

go to T24/1 (LPTPC area):

- use (black) key from interlock

- go into T24/1 area, close door, use black key in keyhole next to door -> big red light on

- push the white buttons "Absuche" below the three red "Not Aus" (emergency stop) buttons

- go back to the door, turn key and keep it turned!

- open the door, move out and close it again behind you

- now it is the time to return the key again -> two green lights should go on

power bending magnets:

- choose beam energy according to list sticked to monitor

get beam:

- phone Control Room 3500

- tell them to put the wire into DesyII at the position written in their lock book

open shutter:

- go back to hut

- put back the red and black keys into the interlock

- turn all four keys -> 5 green lights should be on next to each pair of keys

- open shutter T24 with the button "Beam Shutter auf" -> bottom green light next to the keys should go out

- open shutter T24/1 with the button "Beam Shutter auf" -> bottom green light next to the keys should go out

- now you should see beam

-> start data taking

|

|

15

|

Tue Nov 3 11:18:46 2009 |

Stephan Hänsel | Setup | Beam Off |

close shutter:

- close shutter T24/1 with the button "Beam Shutter zu" (green) -> bottom green light next to the keys should go on

- close shutter T24 with the button "Beam Shutter auf" (green) -> bottom green light next to the keys should go on

- turn all four keys -> (the top) 4 green lights should go out next to each pair of keys

go to T24/1 (LPTPC area):

- just open the door -> the two green and the big red lights go out

If you do not need the test beam any more:

- open door at test beam area T24 -> the two green and the big red lights go out

- call Control Room 3500

- switch off bending magnets

|

|

16

|

Wed Nov 4 15:29:00 2009 |

Stephan Hänsel | Measurements | Run 20055 - Pedestal |

|

|

17

|

Wed Nov 4 15:31:39 2009 |

Stephan Hänsel | Measurements | Run 20055 - Pedestal |

15399 triggers

HV: 200V -> 2µA

LV:

- 01,30 / 02,60 // 01.30 / 02.60

- 0,621 / 1,722 // 0,610 / 1,734

|

|

18

|

Wed Nov 4 16:10:24 2009 |

Stephan Hänsel | Measurements | Run 20056 - Micromegas #805 |

10989 events

HV: 200V -> 2µA

LV:

- 01,30 / 02,60 // 01.30 / 02.60

- 0,621 / 1,722 // 0,610 / 1,734

trigger rate 7,25Hz

!!!!! in eventfile: time-stamp instead of real trigger number !!!!!

|

|

19

|

Wed Nov 4 16:12:33 2009 |

Stephan Hänsel | Measurements | Run 20057 - Micromegas #806 |

1076 events

trigger rate 7,25Hz

bx = real trigger number

HV: 200V -> 2µA

LV:

- 01,30 / 02,60 // 01.30 / 02.60

- 0,621 / 1,722 // 0,610 / 1,734

|

|

20

|

Wed Nov 4 16:31:42 2009 |

Stephan Hänsel | Measurements | Run 20059 - Micromegas #807 |

crashed at 3648 events -> TPC got much more events

Beam: 5,6 GeV

one Micromegas module in center position

silicon sledge 35cm inside from TPC-support-front

HV: 200V -> 2µA

LV:

- 01,30 / 02,60 // 01.30 / 02.60

- 0,621 / 1,722 // 0,610 / 1,734

|