| ID |

Date |

Author |

Project |

Subject |

Run Number |

Events |

StartTime |

EndTime |

|

28

|

Thu Aug 20 12:35:13 2009 |

Christian Irmler | alignment_beam | top right on sensor, point 3 | run6865 | 10600 | 20.08.2009 12:31:35 | 20.08.2009 12:48:04 |

2 alignement modules

location in beam direction: h04-h03

beam in center of sensor

HV=70V, 40MHz, 6 samples

beam on, 120 GeV

module 1 (h03) is used w inverter off and higher base line

XY coordinates: X:43 y:121.3 (top right on sensor in beam direction) |

|

27

|

Thu Aug 20 12:18:40 2009 |

Christian Irmler | alignment_beam | top left on sensor, point 2 | run6863 (telescope 6864) | 10600 | 20.08.2009 12:07:28 | 20.08.2009 12:25:57 |

2 alignement modules

location in beam direction: h04-h03

beam in center of sensor

HV=70V, 40MHz, 6 samples

beam on, 120 GeV

module 1 (h03) is used w inverter off and higher base line

XY coordinates: X:57 y:121.3 (top left on sensor in beam direction) |

|

26

|

Thu Aug 20 11:38:11 2009 |

Christian Irmler | alignment_beam | top center, point 7 | run6861 (+6862) | 10600 | 20.08.2009 11:36:35 | 20.08.2009 11:53:51 |

2 alignement modules

location in beam direction: h04-h03

beam in center of sensor

HV=70V, 40MHz, 6 samples

beam on, 120 GeV

module 1 (h03) is used w inverter off and higher base line

XY coordinates: X:50 y:121.3 (top center, point 7) |

|

25

|

Thu Aug 20 11:23:04 2009 |

Christian Irmler | alignment_beam | beam in center of sensor w telescope | run004 (6860 telescope) | 10600 | 20.08.2009 11:09:50 | 20.08.2009 11:25:16 |

2 alignement modules

location in beam direction: h04-h03

beam in center of sensor

HV=70V, 40MHz, 6 samples

beam on, 120 GeV

module 1 (h03) is used w inverter off and higher base line

XY coordinates: X:50 y:141.3 (center- center, point 1) |

|

24

|

Thu Aug 20 11:05:26 2009 |

Christian Irmler | alignment_beam | pedeatal correction | pedcorr002 | | 20.08.2009 11:05:41 | 20.08.2009 11:09:35 |

2 alignement modules

location in beam direction: h04-h03

HV=70V, 40MHz, 1 sample

beam on

module 1 (h03) is used w inverter off and higher base line |

|

23

|

Thu Aug 20 10:48:39 2009 |

Christian Irmler | alignment_beam | internal calibration | cal002 | | 20.08.2009 10:49:07 | 20.08.2009 10:59:43 |

2 alignement modules

location in beam direction: h04-h03

HV=70V, 40MHz, 1 sample

no beam

module 1 (h03) is used w inverter off and higher base line |

|

22

|

Thu Aug 20 00:31:45 2009 |

Christian Irmler | ITE128 | ITE128 shooting into strips w pitch adapter, upper position | run003 | 100600 | 20.08.2009 00:27:36 | |

DUT: SiLC 08_1, 6 x ITE128, SiLC 08_2

HV = 70V, 40MHz, 120 GeV

TLU trigger, w/o telescope

9x9 mm beam spot

height (y) = 139.3100

ITE128 shooting into strips w pitch adapter, upper edge of sensor |

|

21

|

Thu Aug 20 00:16:45 2009 |

Christian Irmler | ITE128 | pedestal correction | pedcorr001 | | 20.08.2009 00:14:21 | 20.08.2009 00:24:28 |

DUT: SiLC 08_1, 6 x ITE128, SiLC 08_2

HV = 70V, 40MHz

pedestal correction

beam on

|

|

20

|

Wed Aug 19 22:57:13 2009 |

Marko Dragicevic | | How-To | | | | |

TLU (run from DAQPCHEPHY):

ssh eudet@eudetmac001.cern.ch

ssh tlupc

~\eudaq\bin\TLUControl.exe -d1 -a12

-t100 internal trigger

-aXX Mask for Szintis:

1 4 mm (front)

2 4 mm (front)

4 9 mm (back)

8 9 mm (back)

DAQ:

Hostname: DAQPCHEPHY.CERN.CH

XY Table PC:

Hostname: XYPCEUDET.CERN.CH

Beam Control:

Hostname: cwo-hna453-h6b1.cern.ch

137.138.61.206

Eudet DAQ:

vnc eudetmac001.cern.ch

Cycle Run:

o) stop DAQ

o) kill eudaq Run Control

o) restart: ./STARTRUN.FORTIS.1

o) load config: testfortis_with_eudrb_beam_backpressure_WITH_SILC

o) press: Config (wait ~1 min.)

o) press: Start |

|

19

|

Wed Aug 19 22:56:07 2009 |

Christian Irmler | ITE128 | ITE128 shooting into strips w pitch adapter, upper position | run002 | 100600 | 19.08.2009 22:54:23 | 20.08.2009 00:11:31 |

DUT: SiLC 08_1, 6 x ITE128, SiLC 08_2

HV = 70V, 40MHz, 120 GeV

TLU trigger, w/o telescope

9x9 mm beam spot

height (y) = 144.3099

ITE128 shooting into strips w pitch adapter, upper position |

|

18

|

Wed Aug 19 20:43:14 2009 |

Christian Irmler | ITE128 | ITE128 shooting into strips w/o pitch adapter, low position | run001 | 100600 | 19.08.2009 20:42:08 | 19.08.2009 22:54:21 |

DUT: SiLC 08_1, 6 x ITE128, SiLC 08_2

HV = 70V, 40MHz, 120 GeV

TLU trigger, w/o telescope

9x9 mm beam spot

height (y) = 154.0979

ITE128 shooting into strips w/o pitch adapter, low position |

|

17

|

Wed Aug 19 15:41:17 2009 |

Wolfgang Kiesenhofer | SiLC | angle scan templates | | | | |

Linie am rechten Seitenrand (in der Vorschau unten leider nicht gut zu sehen) sollte mit dem rechten Rand der Basisplatte abschließen (bezogen auf die Beam Richtung). |

| Attachment 1: angle_scan0.pdf

|

| Attachment 2: angle_scan5.pdf

|

| Attachment 3: angle_scan10.pdf

|

| Attachment 4: angle_scan15.pdf

|

| Attachment 5: angle_scan20.pdf

|

| Attachment 6: angle_scan25.pdf

|

| Attachment 7: angle_scan30.pdf

|

| Attachment 8: angle_scan35.pdf

|

| Attachment 9: angle_scan40.pdf

|

| Attachment 10: angle_scan45.pdf

|

| Attachment 11: angle_scan50.pdf

|

| Attachment 12: angle_scan55.pdf

|

| Attachment 13: angle_scan60.pdf

|

|

16

|

Wed Aug 19 15:37:37 2009 |

Christian Irmler | ITE128 | internal calibration | cal001 | | 15:31:29 | |

8 modules, HV=70V, 40MHz, 1 sample

no beam

APV 4,5: inverter off, higher baseline = PAD modules |

|

15

|

Fri Aug 14 21:36:17 2009 |

Markus Friedl | | Config files | | | | |

Status of config files as of Friday 14 August 2009 late evening

| Config file name |

Timing adjusted |

Sensor definition |

Tested |

| cern09_ite128_single1 |

YES |

NOT YET (?) |

YES |

|

cern09_ite128_multi6

|

YES |

NOT YET (?) |

YES |

|

cern09_pt_ite512_single1

|

YES |

NOT YET (?) |

YES |

|

cern09_pt_ite512_multi6

|

YES |

NOT YET (?) |

NO |

|

cern09_alignment_beam_single1

|

YES |

NOT YET (?) |

YES |

|

cern09_alignment_beam_multi6

|

YES |

NOT YET (?) |

YES |

|

cern09_belle_single

|

YES |

NOT YET (?) |

YES |

|

cern09_belle_multi6

|

YES |

NOT YET (?) |

YES |

| cern09_silc_all_single |

YES (2008) |

YES (2008) |

NO |

| cern09_silc_all_multi6 |

YES (2008) |

YES (2008) |

NO |

|

|

14

|

Fri Aug 14 19:35:43 2009 |

Thomas Bergauer | Pt_ITE512 | intcal | | | | |

HV=100V except h05-ITE-512 and h06-ITE-512 (runaway, HV off)

h01-Pt: 10uA

h02-Pt: 1.6uA

3 SiLC DUTs mit je ca. 38nA

h07-ITE-512: 3.77uA

h05-ITE-512: breakthrough

h06-ITE-512: breakthrough |

|

13

|

Fri Aug 14 16:45:25 2009 |

Stephan H�nsel | | Module - Setups | | | | |

- 5mm Inbus-Schlüssel

- 3mm Inbus Schlüssel

- 6- 2(1) x 30 Pt-Pins

- beim 5mm-Sockel müssen die 2 Löcher über die das optische Modul h03 verschraubt wird noch ausgeweitet werden (Thomas)

- bei Pt-Deckel oben einzeichnen welche Balkenstellung welchem Winkel entspricht

(SK) ... SenkKopf

(ZK) ... ZylinderKopf

OPTISCHER SETUP - Setup-alignment-modules

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) Collimator

- Alu-Spacer (neuer = höheren verwenden) + 4- M6 x 15 (ZK)

- schwarzer-Spanier-x-y-z-Tisch - Schreuben dabei -> Plastikschrauben abschneiden ?!?

2) 5mm Spacer + h03 - backplane richtung Collimator - APV3210

- 2- M4 x 15 (SK) - 5mm Spacer durch Alignment-Boden mit h03 verschrauben

- 3- M4 x 15 (SK) - Alignment-Boden auf Drehteller verschrauben

3) h04 - backplane richtung Collimator - APV3210

- 2 Positionen

- 2- M4 x 10 (SK)

Pt + ITE-512-Stack + 3 SiLC08-Module

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h06-ITE-512 - APV0123 (allerdings nur eineinhalb APVs gebondet!)

2) h05-ITE-512 - APV0123

3) h07-ITE-512 - APV3210 !!!

4) SiLC08-2 - APV12 - 90° gedreht

5) SiLC08-1 - APV12 - 90° gedreht

6) SiLC08-0 - APV12 - 90° gedreht

Stack 1) bis 6)

- schwarzer Sockel +4- M4 x 35 (ZK) -> verschraubt in h06 und h07

- 2 Gewindestangen M6 x 80 + 4 Scheiben + 4 Muttern M6 -> die 3 ITE-512er zusammen

- 3 Gewindestangen M6 x 160 + 6 Scheiben + 5 Flügelmuttern M6 + 1 Mutter M6 -> 3- SiLC08-Module VORSICHTIG dazu

7) h02-Pt - APV0123 - überprüfen - kann rotieren ;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

8) h01-Pt - APV0123 - überprüfen - kann rotieren;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

ITE128-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h21_alignment-TS05 - APV12 - 90°gedreht

2) h13_ITE-PAS - APV1

3) h14_ITE-PAS - APV1

4) h15_ITE-PAD - APV1

5) h16_ITE-PAD - APV1

6) h11_ITE-STD - APV1

7) h12_ITE-STD - APV1

8) h22-alignment-TS07 - APV12 - 90°gedreht

Schrauben verwenden je nach Sockel und Spacer

SiLC08-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) SiLC08-7 - APV12 - Überprüfen

2) SiLC08-6 - APV12 - Überprüfen

3) SiLC08-5 - APV12 - Überprüfen

4) SiLC08-4 - APV12 - Überprüfen

5) SiLC08-3 - APV12 - Überprüfen

6) SiLC08-2 - APV12 - Überprüfen

7) SiLC08-1 - APV12 - Überprüfen

8) SiLC08-0 - APV12 - Überprüfen

Schrauben verwenden je nach Sockel und Spacer |

|

12

|

Tue Aug 11 14:03:57 2009 |

Marko Dragicevic | | Sensor Designs | | | | |

Screenshots

HEPHY Gallery

GDS File Viewer

KLayout Website

Layer Properties File Warsaw.lyp in den Attachments. |

| Attachment 1: Wafer.gds

|

| Attachment 2: SensorSTD.gds

|

| Attachment 3: SensorPAS.gds

|

| Attachment 4: SensorPAD.gds

|

| Attachment 5: Sensor512.gds

|

| Attachment 6: Warsaw.lyp

|

<?xml version="1.0"?>

<layer-properties>

<properties>

<frame-color>#01ff6b</frame-color>

<fill-color>#01ff6b</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I3</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>NPlus</name>

<source>1/0@1</source>

</properties>

<properties>

<frame-color>#ff0000</frame-color>

<fill-color>#ff0000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I9</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PPlus</name>

<source>2/0@1</source>

</properties>

<properties>

<frame-color>#ff8000</frame-color>

<fill-color>#ff8000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Via</name>

<source>3/0@1</source>

</properties>

<properties>

<frame-color>#00ffff</frame-color>

<fill-color>#00ffff</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I15</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Metal</name>

<source>4/0@1</source>

</properties>

<properties>

<frame-color>#ff00ff</frame-color>

<fill-color>#ff00ff</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I2</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Passivation</name>

<source>5/0@1</source>

</properties>

<properties>

<frame-color>#91ff00</frame-color>

<fill-color>#91ff00</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I3</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PolySilicon</name>

<source>6/0@1</source>

</properties>

<properties>

<frame-color>#008050</frame-color>

<fill-color>#008050</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I2</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>PolySiHeads</name>

<source>7/0@1</source>

</properties>

<properties>

<frame-color>#ffa080</frame-color>

<fill-color>#ffa080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Via2</name>

<source>8/0@1</source>

</properties>

<properties>

<frame-color>#000080</frame-color>

<fill-color>#000080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I12</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Metal2</name>

<source>10/0@1</source>

</properties>

<properties>

<frame-color>#ffa080</frame-color>

<fill-color>#ffa080</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I1</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Margins</name>

<source>11/0@1</source>

</properties>

<properties>

<frame-color>#805000</frame-color>

<fill-color>#805000</fill-color>

<frame-brightness>0</frame-brightness>

<fill-brightness>0</fill-brightness>

<dither-pattern>I0</dither-pattern>

<visible>true</visible>

<transparent>false</transparent>

<width>1</width>

<marked>false</marked>

<animation>0</animation>

<name>Dicing Lines</name>

<source>12/0@1</source>

</properties>

<custom-dither-pattern>

<pattern>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

<line>................................</line>

</pattern>

<order>1</order>

<name></name>

</custom-dither-pattern>

</layer-properties>

|

|

11

|

Fri Jul 31 19:23:26 2009 |

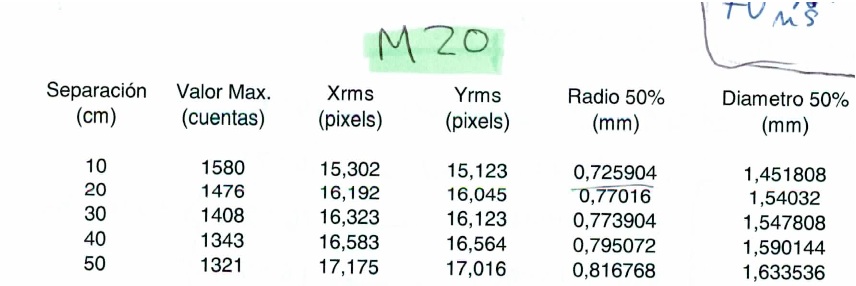

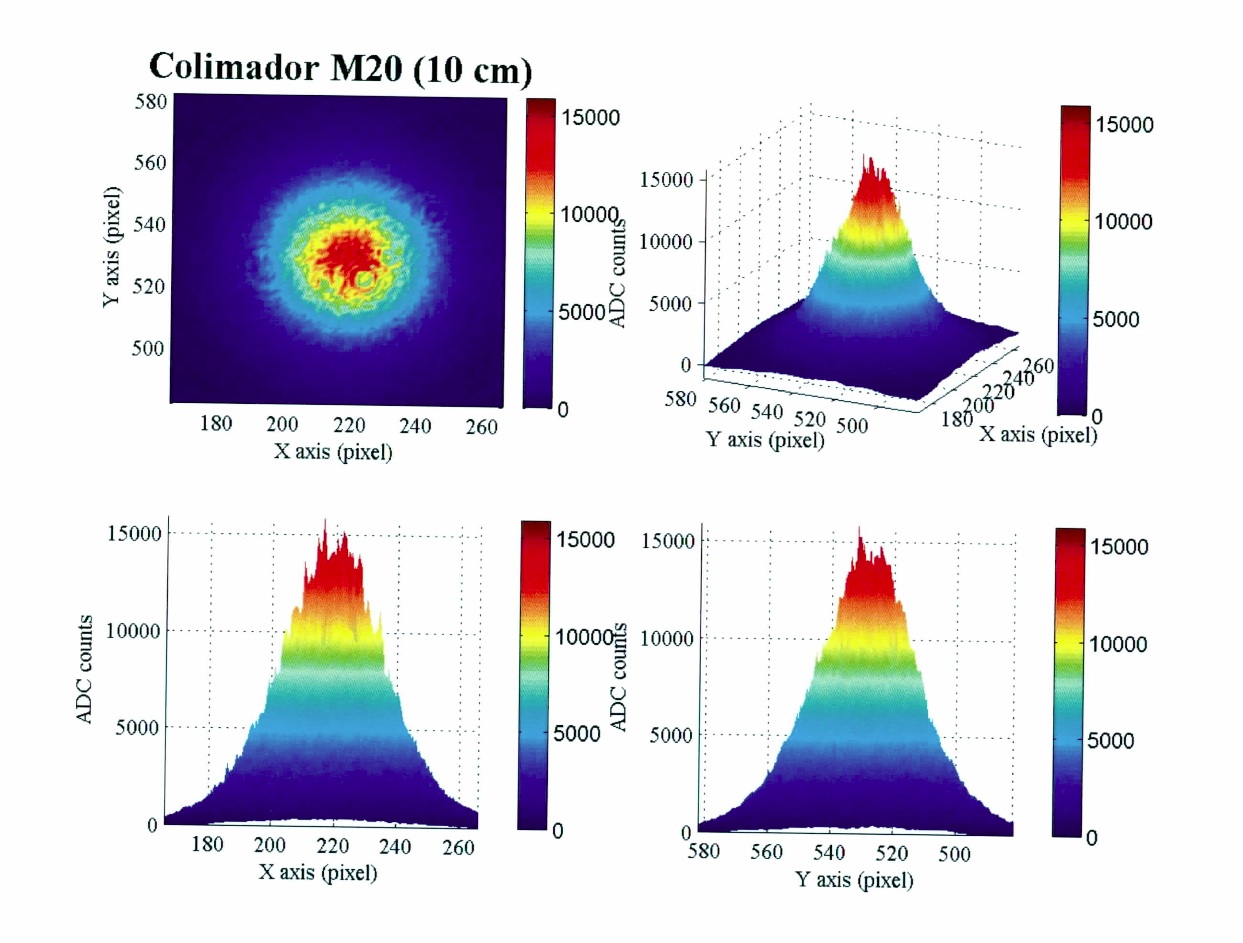

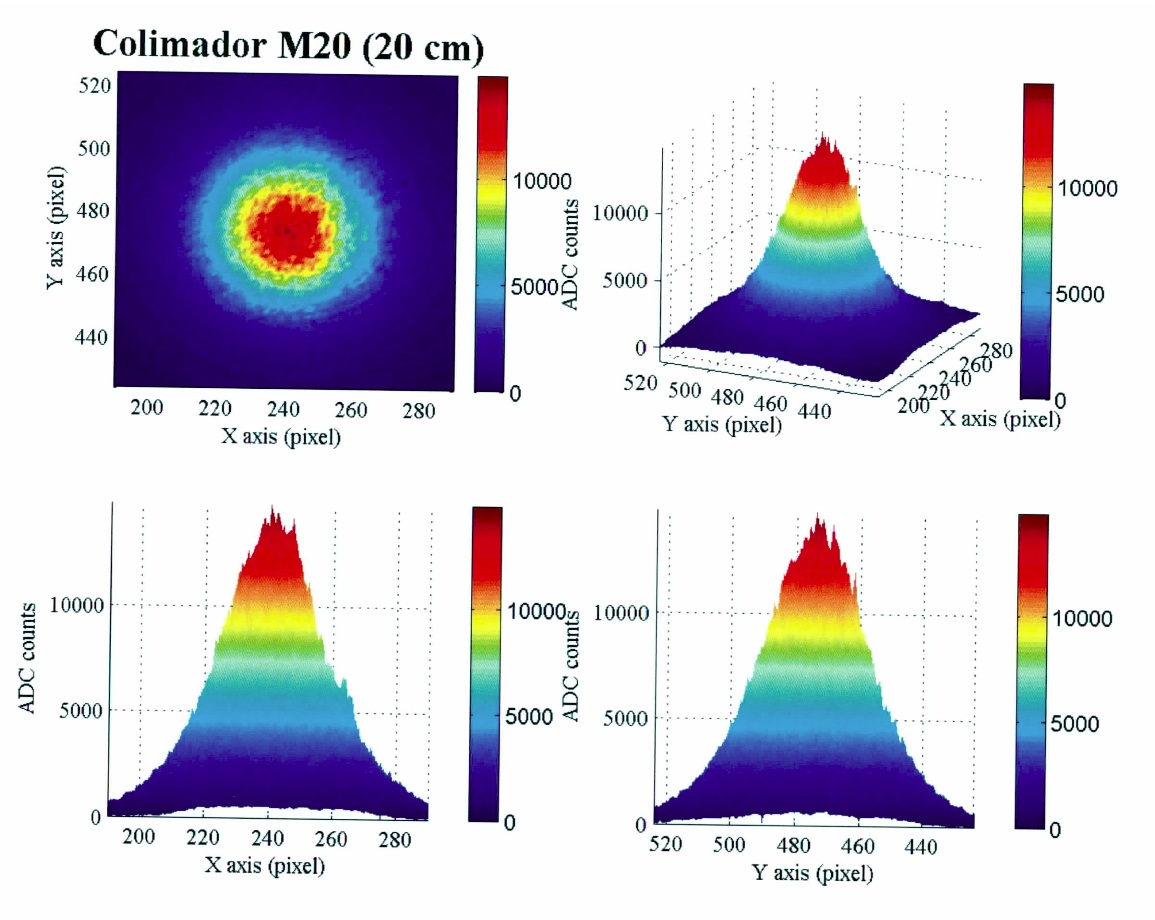

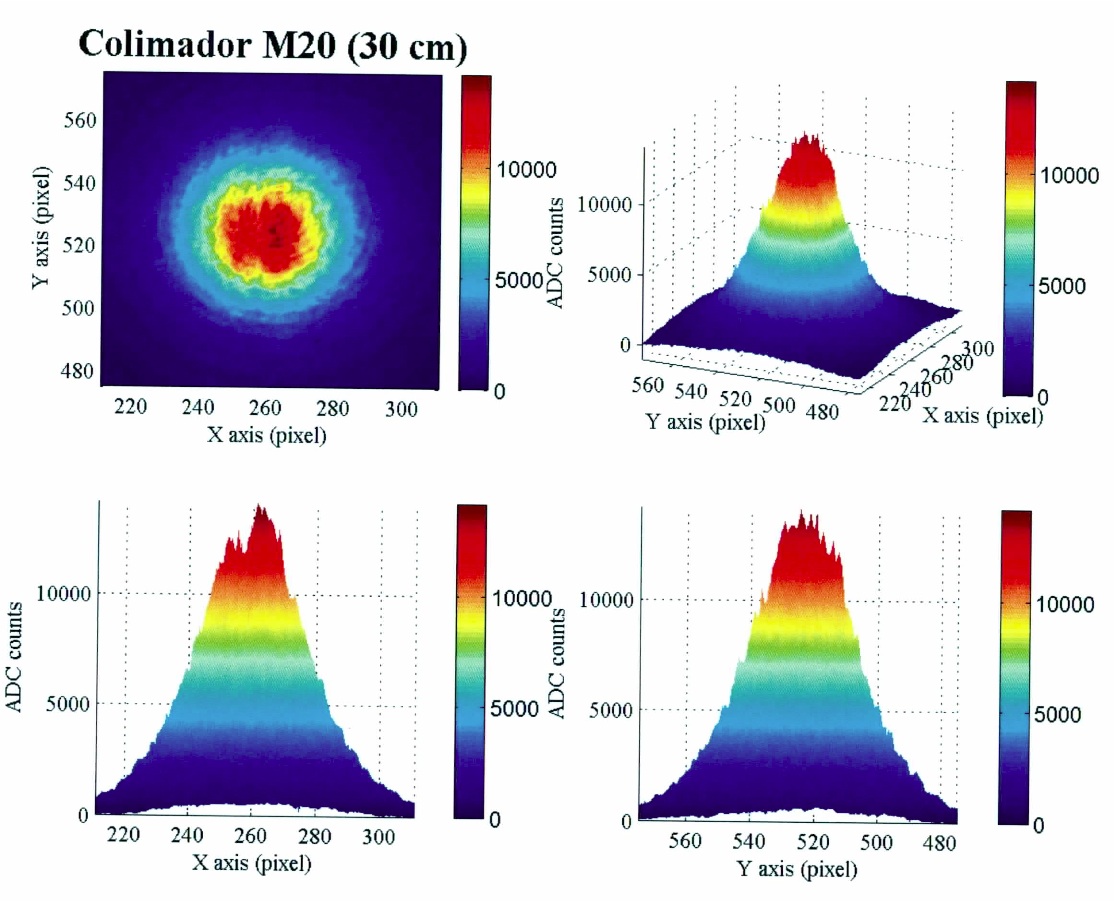

Thomas Bergauer | | Laser Spot size | | | | |

| 10cm nach Kollimator: Durchmesser 1.45mm (FWHM)

20cm nach Kollimator: Durchmesser 1,54mm (FWHM) |

| Attachment 1: laser_spot_overview.jpg

|

|

| Attachment 2: laser_spot_10cm.jpg

|

|

| Attachment 3: laser_spot_20cm.jpg

|

|

| Attachment 4: laser_spot_30cm.jpg

|

|

|

10

|

Fri Jul 17 14:03:21 2009 |

Stephan H�nsel | | What to measure | | | | |

Origami

Testbeam08 Module

- Anglescan

Pt Modules (2Stück - je 2 Sensoren):

Anglescan

- einzelne module (auch als "stub" (fixer Abstand zwischen ihnen) ?)

wichtig: brauchen wir 2 Testbeam08 module um 90° verdreht für höheninformation??? (sensoren in den Pt-modulen sind nicht 100%ig parallel - MESSEN!)

Optical Modules:(DAUER ca 18 Stunden)

- tests in box mit laserbeam (laser auf anderer Höhe al beam?!? - sonst geht der beam durch den Laser)

ITE Modules:

- 8 ter stack: (2 Testbeam08 module quer + 2 x 1stmetal128 + 2 x 2nd metal 128 + 2 x normal128)

- 2ndmetal512 module 3 stück bauen und im beam versetzt einbauen parasitär bei den spanier-modulen)

zusätliche ideen:

- CMS-Tracker slice (2Pt + 2 optische + 3 2ndmetal512 hintereinander in unterschiedlichen winkeln um einen tracker-slice zu simulieren - CMS-layout !?!)

|

|

9

|

Thu Jul 9 10:29:58 2009 |

Stephan H�nsel | SiLC | Measurements - Modules | | | | |

Pt Modules:

- Sensoren sind Luftfeuhtigkeitsempfindlich

- die Sensoren brauchen einige Zeit unter Spannung bis sie sich bei einem akzeptablen Strom stabilisieren

small Problems:

Optical Modules:

small Problems with h03-Module:

ITE Modules:

|