| ID |

Date |

Author |

Project |

Subject |

Run Number |

Events |

StartTime |

EndTime |

|

7

|

Mon Jul 6 16:22:36 2009 |

Stephan H�nsel | SiLC | Measurements - Sensors | | | | |

Pt Modules:

Optical Modules:

ITE Modules:

|

|

8

|

Mon Jul 6 16:23:51 2009 |

Stephan H�nsel | SiLC | Module Components | | | | |

Pt Modules:

Pt-1:

hybrid: h01-4APV

bottom sensor: 30210331516116

top sensor: 30210332911309

Pt-2:

hybrid: h02-4APV

bottom sensor: 30210331415917

top sensor: 30210314845402

Optical Modules:

Opt_AC-Test-1:

hybrid: h21-2APV

sensor: HPK-ILC-TS-SPL-6687-05

Opt_AC-Test-2:

hybrid: h22-2APV

sensor: HPK-ILC-TS-SPL-6687-07

modules with SiLC alignment sensors:

Opt-1:

hybrid: h03

sensor: HPK-SPL-6686-03

Opt-2:

hybrid: h04

sensor: HPK-SPL-6686-07

ITE Modules: |

|

9

|

Thu Jul 9 10:29:58 2009 |

Stephan H�nsel | SiLC | Measurements - Modules | | | | |

Pt Modules:

- Sensoren sind Luftfeuhtigkeitsempfindlich

- die Sensoren brauchen einige Zeit unter Spannung bis sie sich bei einem akzeptablen Strom stabilisieren

small Problems:

Optical Modules:

small Problems with h03-Module:

ITE Modules:

|

|

10

|

Fri Jul 17 14:03:21 2009 |

Stephan H�nsel | | What to measure | | | | |

Origami

Testbeam08 Module

- Anglescan

Pt Modules (2Stück - je 2 Sensoren):

Anglescan

- einzelne module (auch als "stub" (fixer Abstand zwischen ihnen) ?)

wichtig: brauchen wir 2 Testbeam08 module um 90° verdreht für höheninformation??? (sensoren in den Pt-modulen sind nicht 100%ig parallel - MESSEN!)

Optical Modules:(DAUER ca 18 Stunden)

- tests in box mit laserbeam (laser auf anderer Höhe al beam?!? - sonst geht der beam durch den Laser)

ITE Modules:

- 8 ter stack: (2 Testbeam08 module quer + 2 x 1stmetal128 + 2 x 2nd metal 128 + 2 x normal128)

- 2ndmetal512 module 3 stück bauen und im beam versetzt einbauen parasitär bei den spanier-modulen)

zusätliche ideen:

- CMS-Tracker slice (2Pt + 2 optische + 3 2ndmetal512 hintereinander in unterschiedlichen winkeln um einen tracker-slice zu simulieren - CMS-layout !?!)

|

|

13

|

Fri Aug 14 16:45:25 2009 |

Stephan H�nsel | | Module - Setups | | | | |

- 5mm Inbus-Schlüssel

- 3mm Inbus Schlüssel

- 6- 2(1) x 30 Pt-Pins

- beim 5mm-Sockel müssen die 2 Löcher über die das optische Modul h03 verschraubt wird noch ausgeweitet werden (Thomas)

- bei Pt-Deckel oben einzeichnen welche Balkenstellung welchem Winkel entspricht

(SK) ... SenkKopf

(ZK) ... ZylinderKopf

OPTISCHER SETUP - Setup-alignment-modules

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) Collimator

- Alu-Spacer (neuer = höheren verwenden) + 4- M6 x 15 (ZK)

- schwarzer-Spanier-x-y-z-Tisch - Schreuben dabei -> Plastikschrauben abschneiden ?!?

2) 5mm Spacer + h03 - backplane richtung Collimator - APV3210

- 2- M4 x 15 (SK) - 5mm Spacer durch Alignment-Boden mit h03 verschrauben

- 3- M4 x 15 (SK) - Alignment-Boden auf Drehteller verschrauben

3) h04 - backplane richtung Collimator - APV3210

- 2 Positionen

- 2- M4 x 10 (SK)

Pt + ITE-512-Stack + 3 SiLC08-Module

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h06-ITE-512 - APV0123 (allerdings nur eineinhalb APVs gebondet!)

2) h05-ITE-512 - APV0123

3) h07-ITE-512 - APV3210 !!!

4) SiLC08-2 - APV12 - 90° gedreht

5) SiLC08-1 - APV12 - 90° gedreht

6) SiLC08-0 - APV12 - 90° gedreht

Stack 1) bis 6)

- schwarzer Sockel +4- M4 x 35 (ZK) -> verschraubt in h06 und h07

- 2 Gewindestangen M6 x 80 + 4 Scheiben + 4 Muttern M6 -> die 3 ITE-512er zusammen

- 3 Gewindestangen M6 x 160 + 6 Scheiben + 5 Flügelmuttern M6 + 1 Mutter M6 -> 3- SiLC08-Module VORSICHTIG dazu

7) h02-Pt - APV0123 - überprüfen - kann rotieren ;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

8) h01-Pt - APV0123 - überprüfen - kann rotieren;-)

- Schrauben gehen von oben (ausserhalb der Box): Balken - Box-Deckel - Beilagscheibe - Pt-Modul

- Balken + 4- 2(1) x 30 Pins + 2- Scheiben + 2- M4 x 20

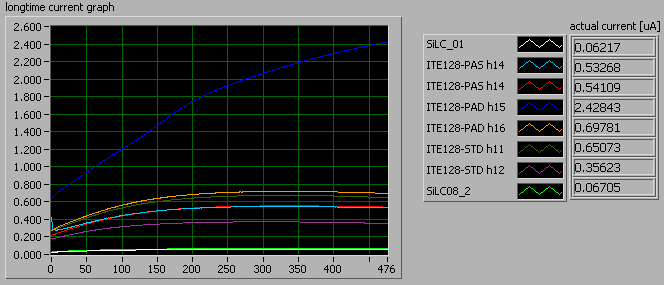

ITE128-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) h21_alignment-TS05 - APV12 - 90°gedreht

2) h13_ITE-PAS - APV1

3) h14_ITE-PAS - APV1

4) h15_ITE-PAD - APV1

5) h16_ITE-PAD - APV1

6) h11_ITE-STD - APV1

7) h12_ITE-STD - APV1

8) h22-alignment-TS07 - APV12 - 90°gedreht

Schrauben verwenden je nach Sockel und Spacer

SiLC08-Stack

upstream - BEAM VON UNTEN - APV-Nummerierung in Beamrichtung von links anfangend

1) SiLC08-7 - APV12 - Überprüfen

2) SiLC08-6 - APV12 - Überprüfen

3) SiLC08-5 - APV12 - Überprüfen

4) SiLC08-4 - APV12 - Überprüfen

5) SiLC08-3 - APV12 - Überprüfen

6) SiLC08-2 - APV12 - Überprüfen

7) SiLC08-1 - APV12 - Überprüfen

8) SiLC08-0 - APV12 - Überprüfen

Schrauben verwenden je nach Sockel und Spacer |

|

11

|

Fri Jul 31 19:23:26 2009 |

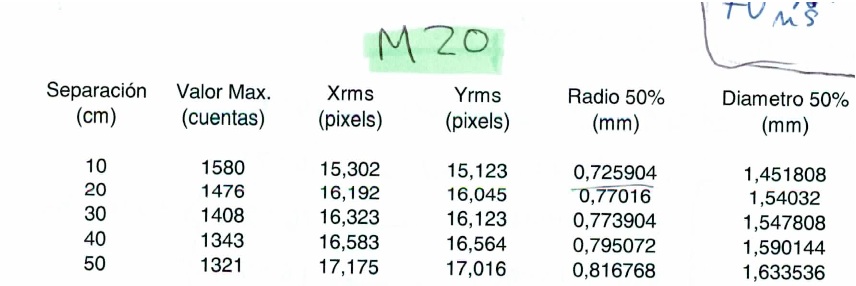

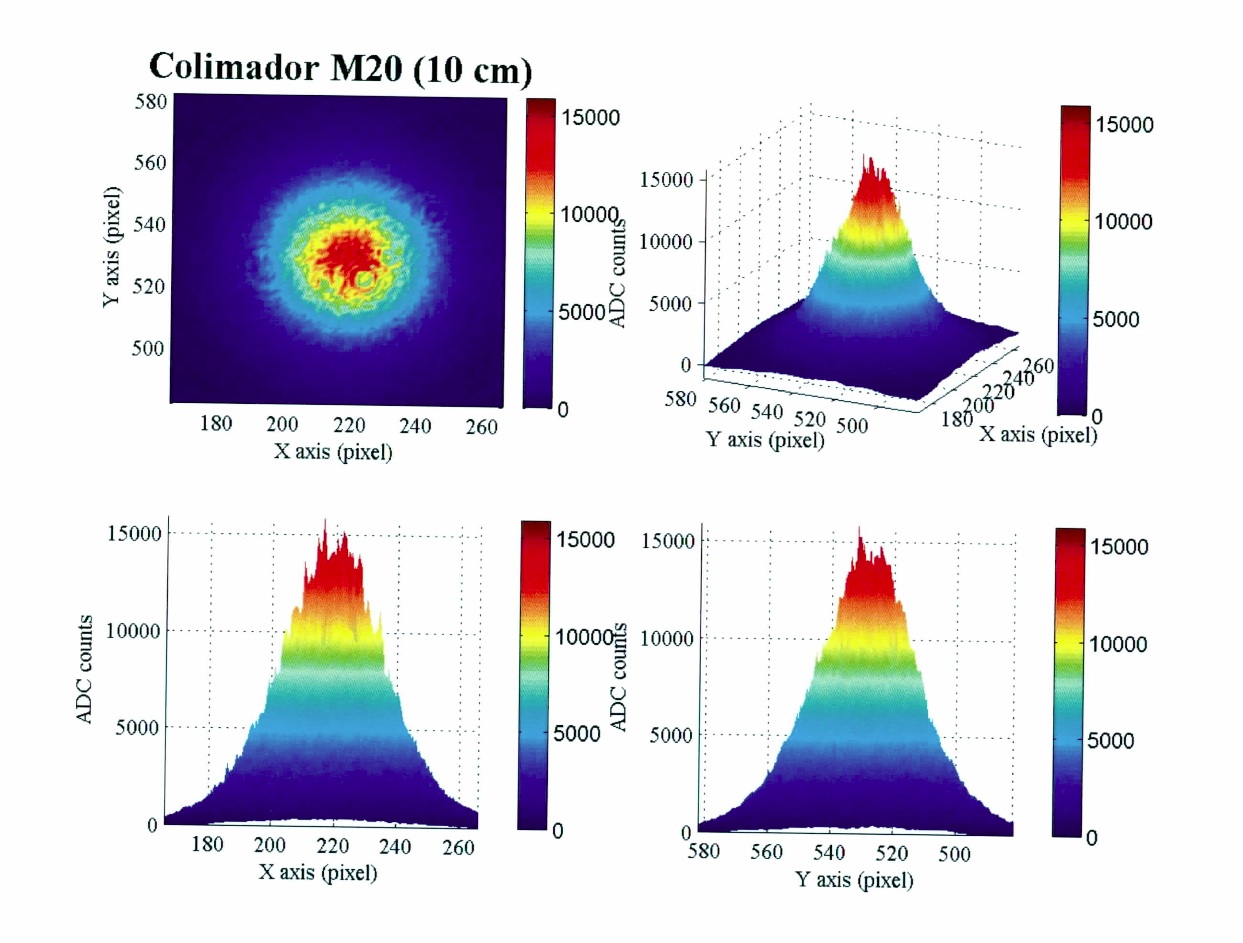

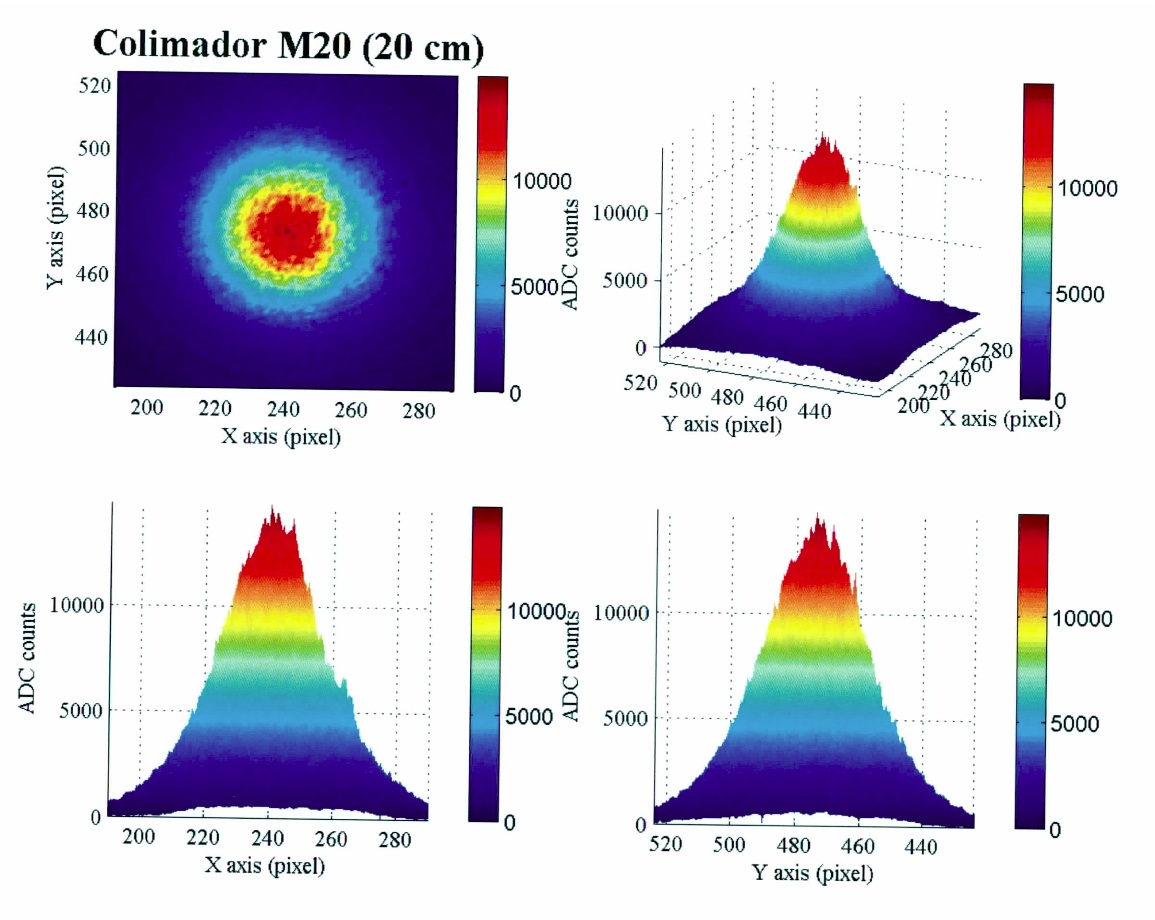

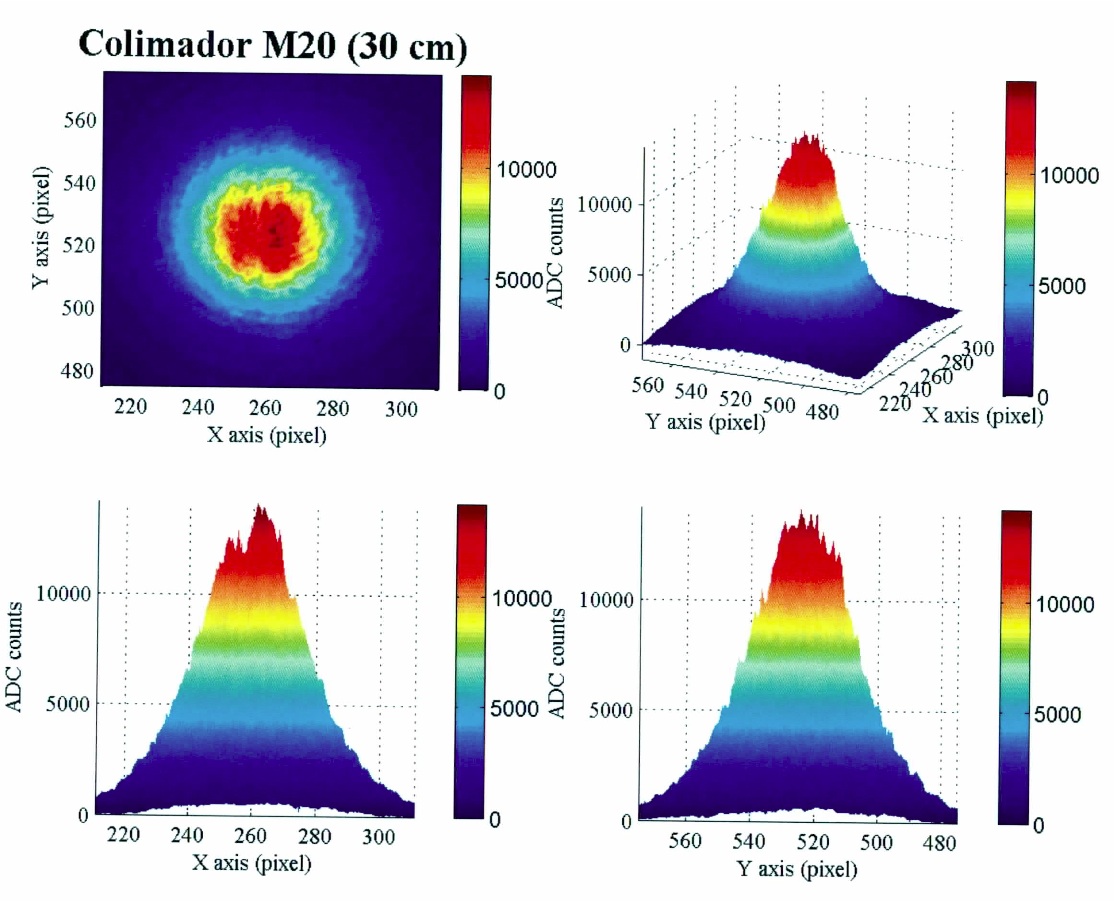

Thomas Bergauer | | Laser Spot size | | | | |

| 10cm nach Kollimator: Durchmesser 1.45mm (FWHM)

20cm nach Kollimator: Durchmesser 1,54mm (FWHM) |

| Attachment 1: laser_spot_overview.jpg

|

|

| Attachment 2: laser_spot_10cm.jpg

|

|

| Attachment 3: laser_spot_20cm.jpg

|

|

| Attachment 4: laser_spot_30cm.jpg

|

|

|

14

|

Fri Aug 14 19:35:43 2009 |

Thomas Bergauer | Pt_ITE512 | intcal | | | | |

HV=100V except h05-ITE-512 and h06-ITE-512 (runaway, HV off)

h01-Pt: 10uA

h02-Pt: 1.6uA

3 SiLC DUTs mit je ca. 38nA

h07-ITE-512: 3.77uA

h05-ITE-512: breakthrough

h06-ITE-512: breakthrough |

|

58

|

Fri Aug 21 22:42:32 2009 |

Thomas Bergauer | common | EUDAQ config file used when running with telescope | | | | |

Used until Friday, 21.08.09:

AndMask = 0xf # 4x4 mm scintillator for trigger

Used since Friday, 21.08.09:

AndMask = 0xc # 9x9 mm scintillator for trigger

Local trigger using TLU only: ALWAYS WITH 9x9mm scintillator

|

| Attachment 1: testfortis_with_eudrb_beam_backpressure_WITH_SILC.conf

|

[RunControl]

RunSizeLimit = 1800000000

NoTrigWarnTime = 10

[DataCollector]

[LogCollector]

SaveLevel = EXTRA

PrintLevel = INFO

[Producer.TLU]

AndMask = 0xc # 9x9 mm scintillaotr for trigger

#AndMask = 0xf # 4x4 mm scintillator for trigger

OrMask = 0

VetoMask = 0

# EUDRB plugged into DUT#4 , FORTIS plugged into DUT#1, SiLC plugged into DUT#0

#DutMask = 20 # EUDRB, FORTIS, SiLC in

DutMask = 17 # FORTIS, SiLC in

EnableDUTVeto = 2#0

TriggerInterval = 0

TrigRollover = 0

StrobePeriod = 16000000

StrobeWidth = 480000

[Producer.EUDRB]

Version = 2

Det = MIMOTEL

Mode = ZS

Unsynchronized = 1

AdcDelay = 3

ClkSelect = 2

#Marker1 = 0xff

#Marker2 = 0xff

PostDetResetDelay = 4

PedestalFile = auto

IDOffset = 0

NumBoards = 6

Board0.Slot = 3

Board1.Slot = 5

Board2.Slot = 7

Board3.Slot = 9

Board4.Slot = 11

Board5.Slot = 13

[Producer.FORTIS]

# Need \ not / for directory name with Cygwin...

# ExecutableDirectory = /home/cussans/optodaq/halsall_test_v5/

ExecutableDirectory = /home/cussans/optodaq/MyF11/

# ExecutableDirectory = /home/cussans/optodaq/MyF10/

ExecutableProcessName = optodaqV.exe

#ExecutableFilename = test_run_128_block_mod_C2.bat

ExecutableFilename = test_run_512_128_block_mod_CX.bat

# ExecutableFilename = test_run_512_448_block_mod_full.bat

ExecutableArgs =

NumRows = 512

NumColumns = 128

|

|

60

|

Sat Aug 22 03:27:13 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 31,8 MHz transparent mode (cooling?) | run014 | 75k | 22.08.2009 03:25:23 | 22.08.2009 07:08:09 |

HV=80V, 31.8 MHz, beam on, 120 GeV

6 samples

chiller set to 13 deg.

f=31.8 MHz

config file: cern09_belle_31.8mhz_multi6.cfg

there was probably no water flow throught the pipe of the origami module during this run --> must be repeated

|

|

61

|

Sat Aug 22 08:32:02 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 31,8 MHz hit mode (cooling?) | run015 | 75k | 22.08.2009 08:15:05 | 22.08.2009 09:25:21 |

HV=80V, 31.8 MHz, beam on, 120 GeV

6 samples, hit mode, hitcut=4

chiller set to 13 deg.

f=31.8 MHz

config file: cern09_belle_31.8mhz_hit_multi6.cfg

there was probably no water flow throught the pipe of the origami module during this run --> must be repeated

|

|

62

|

Sat Aug 22 09:44:50 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 31,8 MHz hit mode (cooling?) | run016 | 75k | 22.08.2009 09:42:38 | 22.08.2009 10:24:05 |

HV=80V, 31.8 MHz, beam on, 120 GeV

6 samples, hit mode, hitcut=5

chiller set to 13 deg.

f=31.8 MHz

config file: cern09_belle_31.8mhz_hit_cut5_multi6.cfg

there was probably no water flow throught the pipe of the origami module during this run!

|

|

63

|

Sat Aug 22 10:28:50 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 40 MHz hit mode (cooling?) | run017 | 75k | 22.08.2009 10:26:28 | 22.08.2009 11:16:12 |

HV=80V, 40 MHz, beam on, 120 GeV

6 samples, hit mode, hitcut=4

chiller set to 13 deg.

f=40 MHz

config file: cern09_belle_hit_multi6.cfg

there was probably no water flow throught the pipe of the origami module during this run!

|

|

64

|

Sat Aug 22 11:26:00 2009 |

Thomas Bergauer | BELLE | APVDAQ + telescope 40 MHz hit mode (cooling?) | run018 | 75k | 22.08.2009 11:16:57 | 22.08.2009 11:58:56 |

HV=80V, 40 MHz, beam on, 120 GeV

6 samples, hit mode, hitcut=5

chiller set to 13 deg.

f=40 MHz

config file: cern09_belle_hit_cut5_multi6.cfg

trigger rate about 3500 ev / spill

there was probably no water flow throught the pipe of the origami module during this run!

|

|

65

|

Sat Aug 22 11:54:49 2009 |

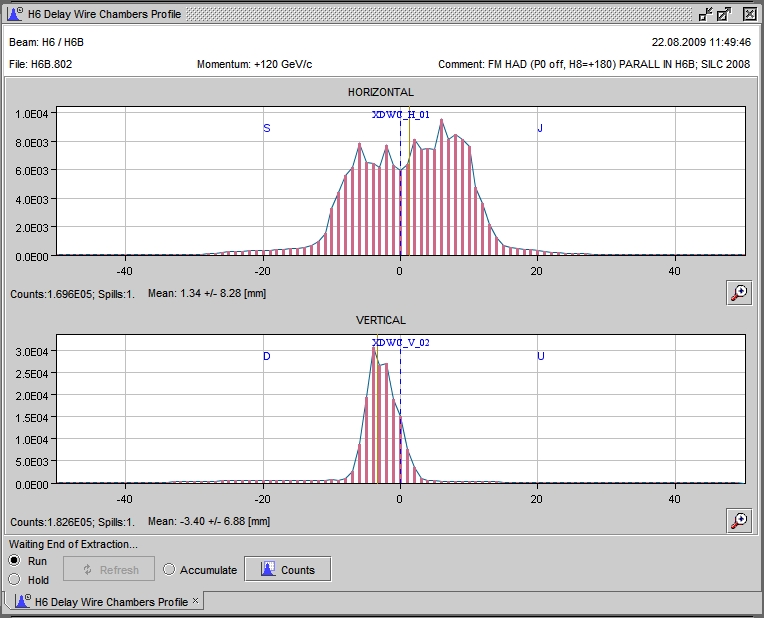

Thomas Bergauer | common | beam profile | | | | |

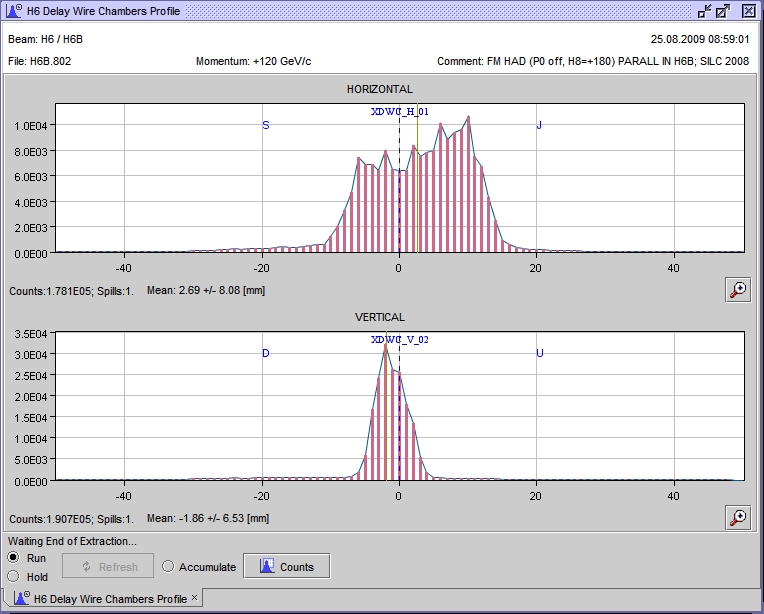

beam shifted a bit in vertical direction downwards since 21. August 09 evening

Beam configuration:

Beam configuration file: H6b.802 (FM HAD (P0 off, H8=+180) PARLALLEL IN H6B SILC 2008 |

| Attachment 1: 20090822_1150_beam_conditions.jpg

|

|

|

71

|

Sat Aug 22 15:12:44 2009 |

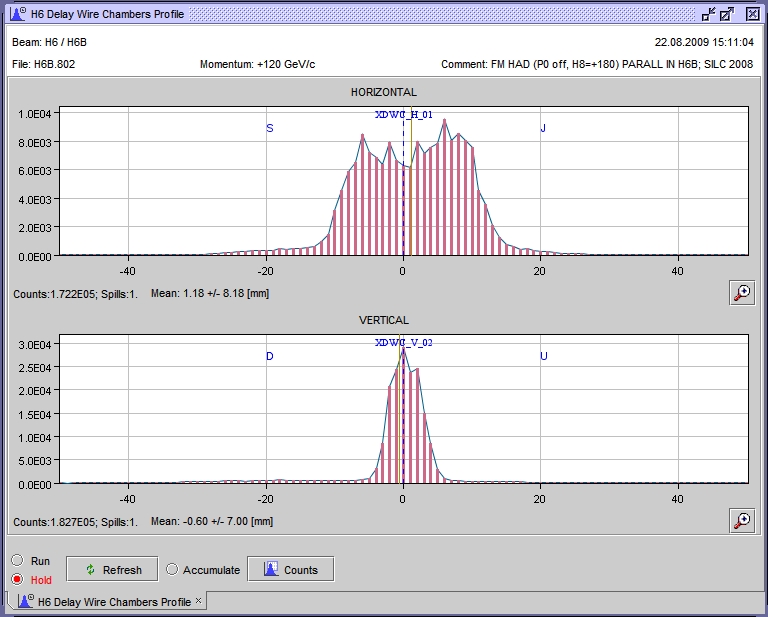

Thomas Bergauer | common | beam profile | | | | |

playing with TRIM4 in vertical plane (setting to 20A current) shifted beamspot back to center position

Beam configuration:

Beam configuration file: H6b.802 (FM HAD (P0 off, H8=+180) PARLALLEL IN H6B SILC 2008

Rate: 3.35E5 particles/spill (measured with SCINT8 in beamline)

Particle Production Applet

Calculator applet

For +120 Gev/c beam:

| Pi+ |

55.67 % |

| p |

38.95 % |

| K+ |

5.38 % |

|

| Attachment 1: 20090822_1511_beam_conditions.jpg

|

|

|

77

|

Sun Aug 23 01:46:03 2009 |

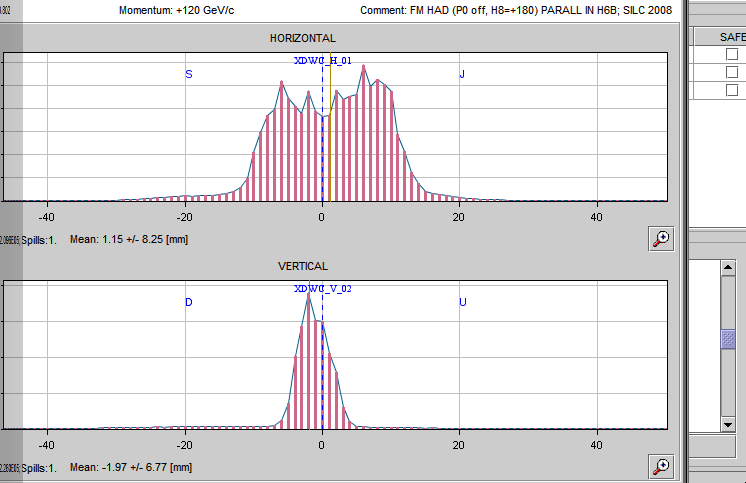

Thomas Bergauer | ITE128 | 2nd run with ITE128: central position | run021 | 100k | 23.08.09 00:10 (ca.) | 23.08.2009 02:15:10 |

ITE128

HV = 70V, 40MHz, 120 GeV

TLU trigger w telescope

XY-Table: x=48, y=115.31

new beam position (used TRIM4 magnet at 7A): y down by 2mm. see attached picture |

| Attachment 1: Picture_1.png

|

|

|

78

|

Sun Aug 23 02:18:20 2009 |

Thomas Bergauer | ITE128 | 2nd run with ITE128: top position (3mm below center); during night | run022 | 407895 | 23.08.2009 02:16:21 | 23.08.2009 08:04:09 |

ITE128

HV = 70V, 40MHz, 120 GeV

TLU trigger w telescope

XY-Table: x=48, y=112.31 |

| Attachment 1: Picture_1.png

|

|

|

79

|

Sun Aug 23 08:13:31 2009 |

Thomas Bergauer | ITE128 | 2nd run with ITE128: top position (4mm below center) | run023 | 100k | 23.08.2009 08:06:58 | 23.08.2009 09:30:53 |

ITE128

HV = 70V, 40MHz, 120 GeV

TLU trigger w telescope

XY-Table: x=48, y=111.31 |

|

94

|

Tue Aug 25 09:00:51 2009 |

Thomas Bergauer | | beam conditions | | | | |

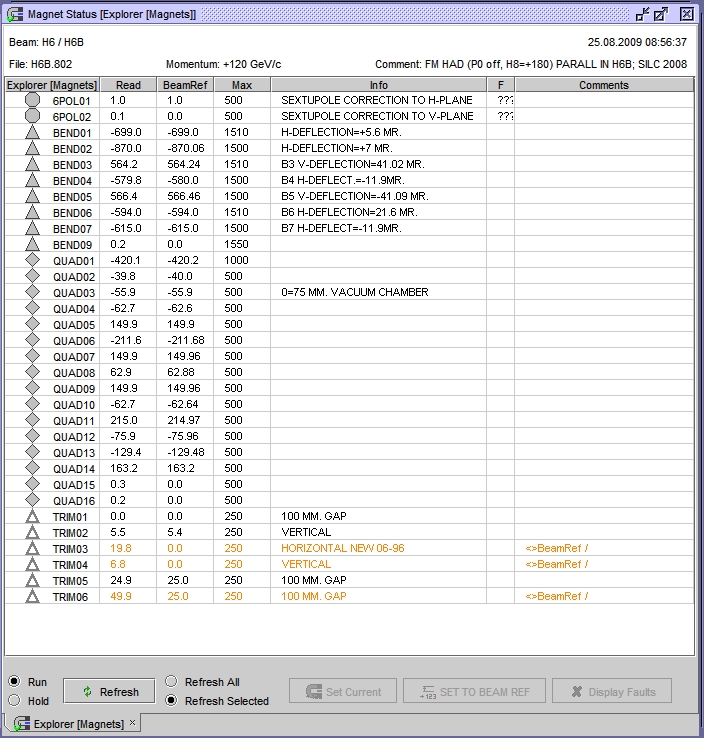

manually changed TRIM3, TRIM4 and TRIM6 |

| Attachment 1: magnet_settings_withH6B.802.jpg

|

|

| Attachment 2: 20090825_0859_beam_conditions.jpg

|

|

|

97

|

Tue Aug 25 11:26:23 2009 |

Thomas Bergauer | Pt_ITE512 | Pt_ITE512 6deg NO air! | run036 | 20k | 25.08.2009 11:25 | 25.08.2009 12:19:55 |

Pt: 6 Grad, HV=200V, 20% (start run) to % (end run) RH, beam on, 120GeV

ITE512: HV=70V,

X-Y-Table: x=99.6, y=36

MOEGLICHERWEISE WAR EIN MODUL AUF 8 GRAD |