| |

ID |

Date |

Author |

Project |

Measurement Type |

Object ID |

Subject |

|

|

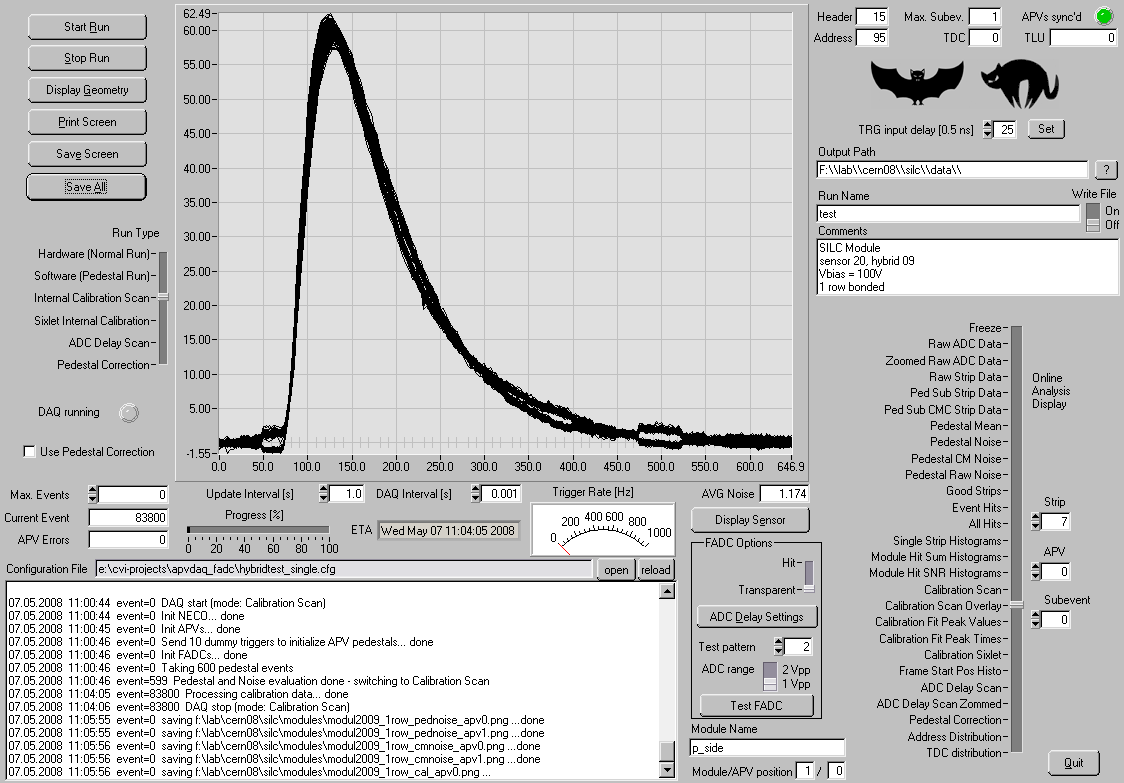

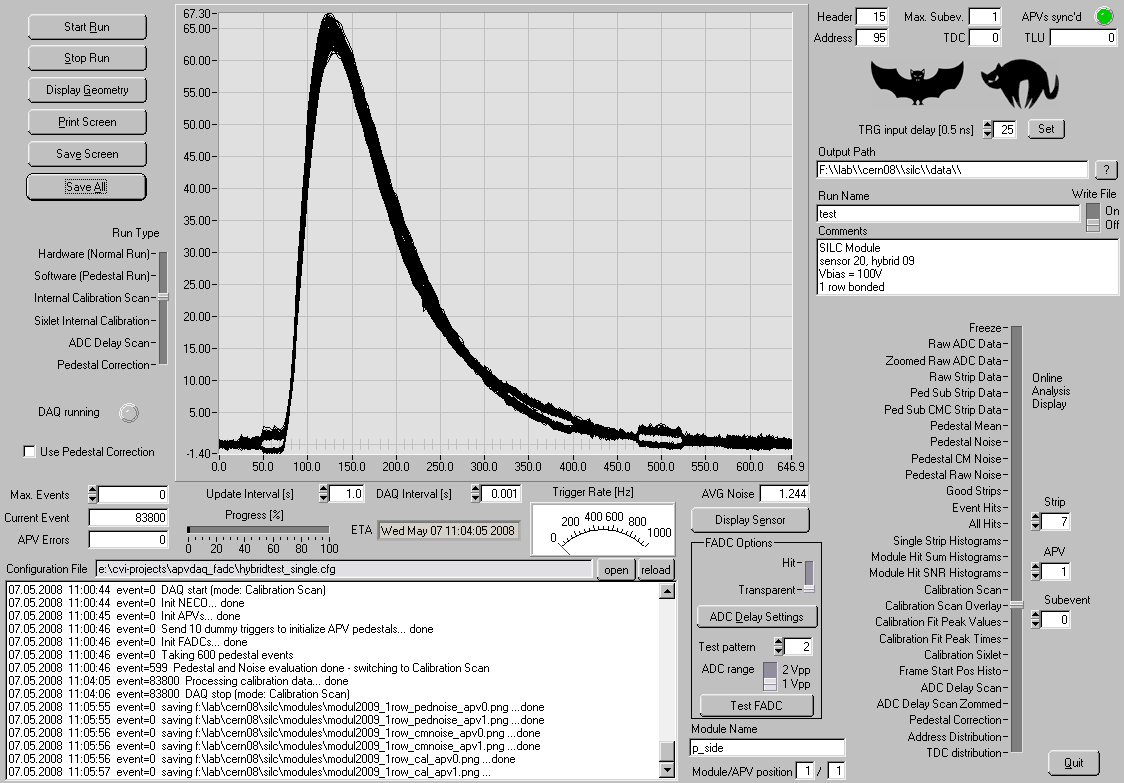

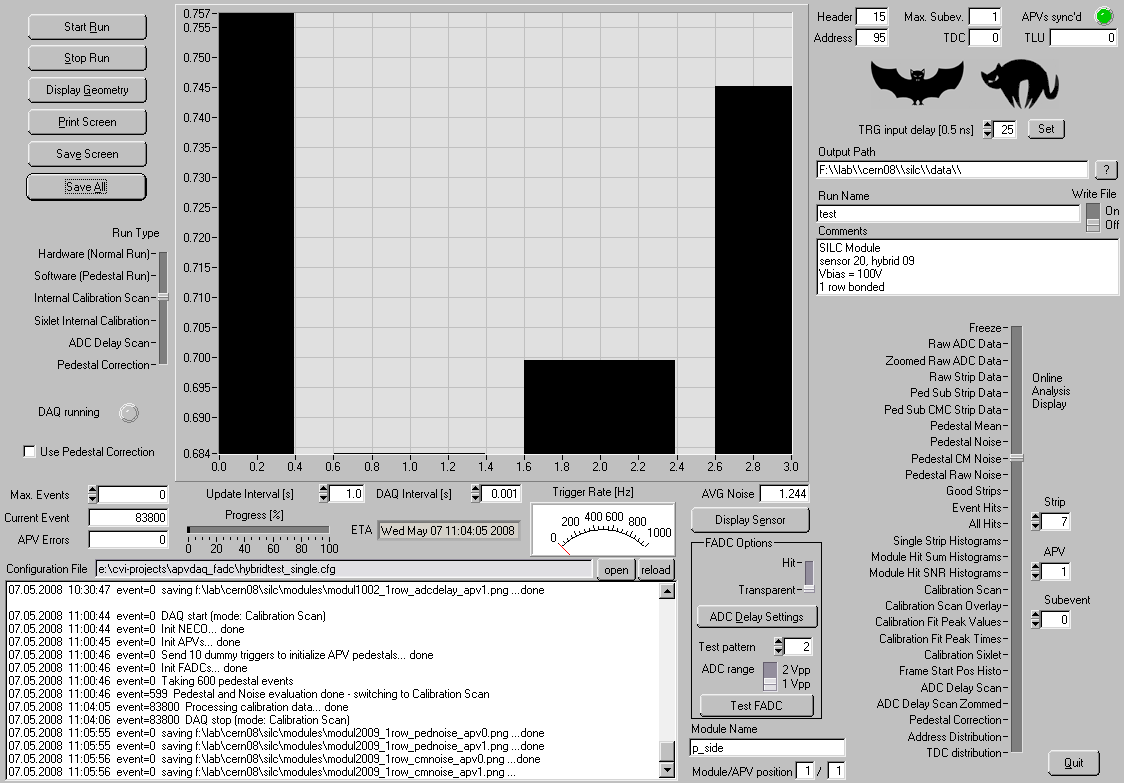

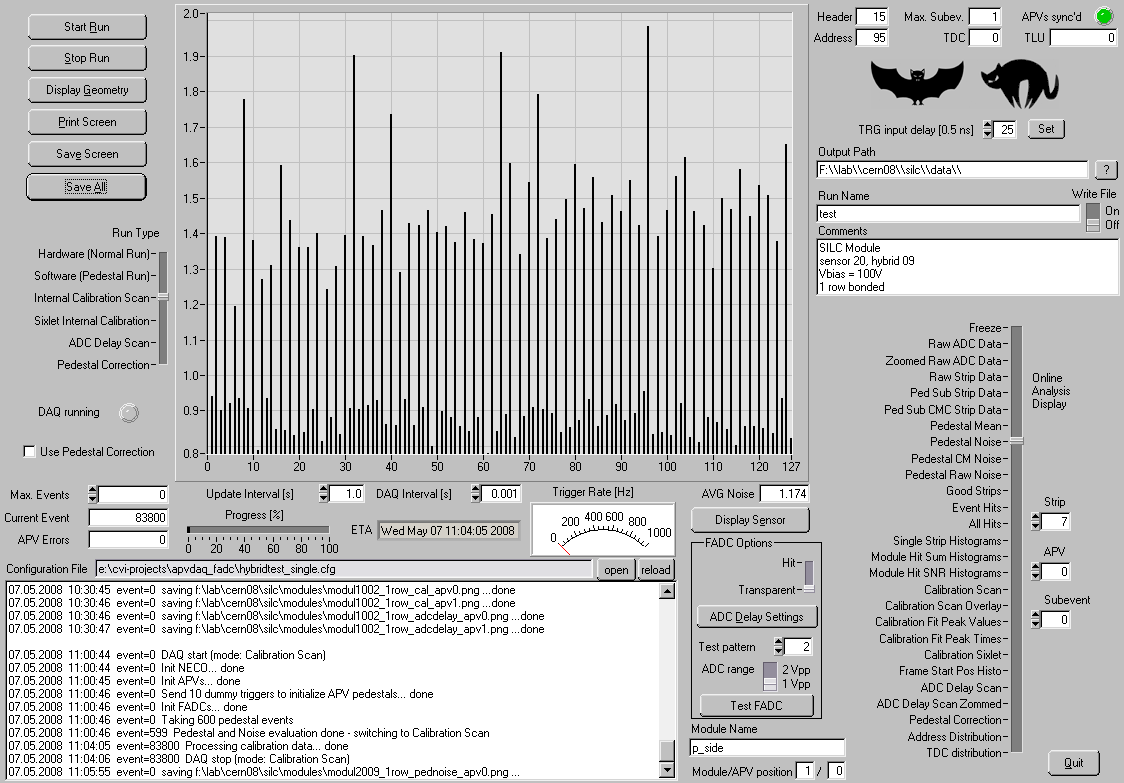

9

|

Wed May 7 15:26:24 2008 |

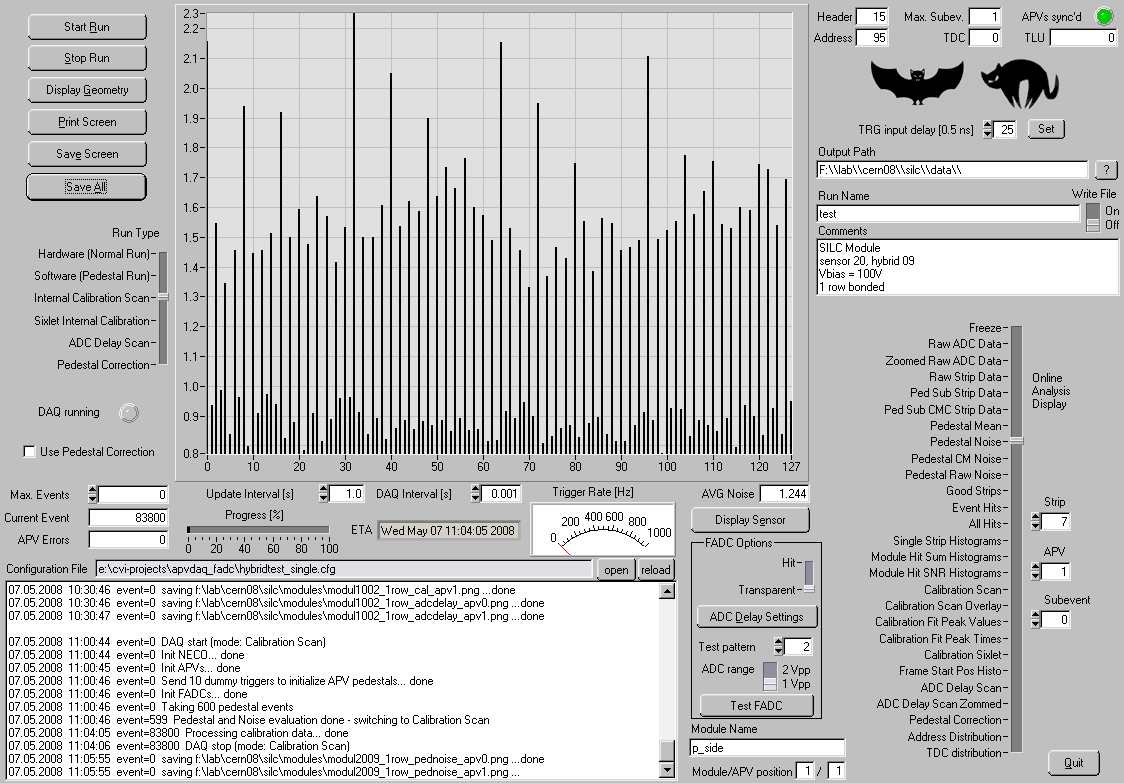

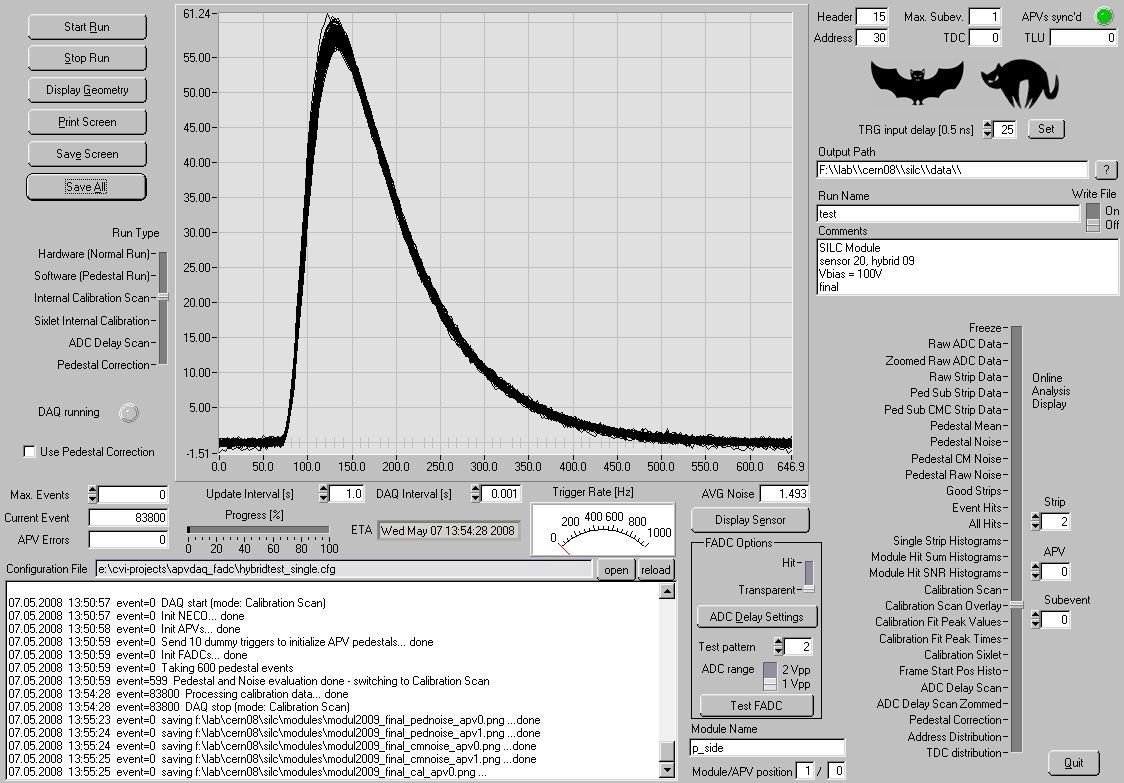

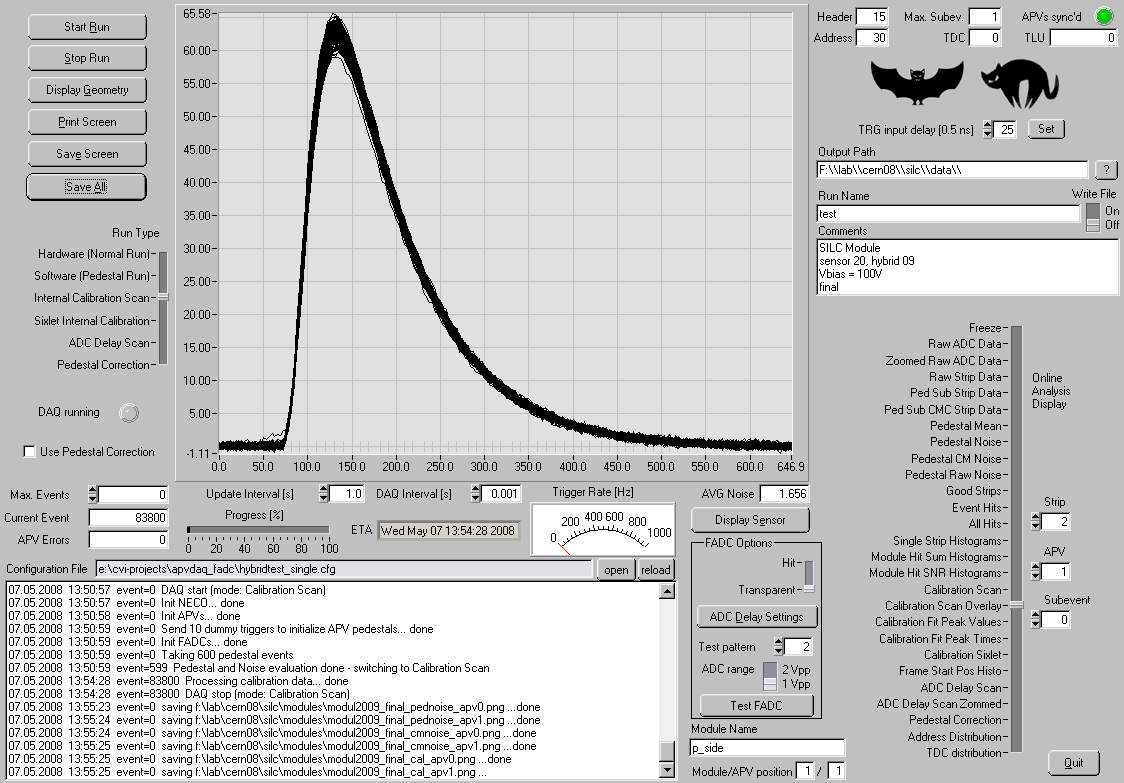

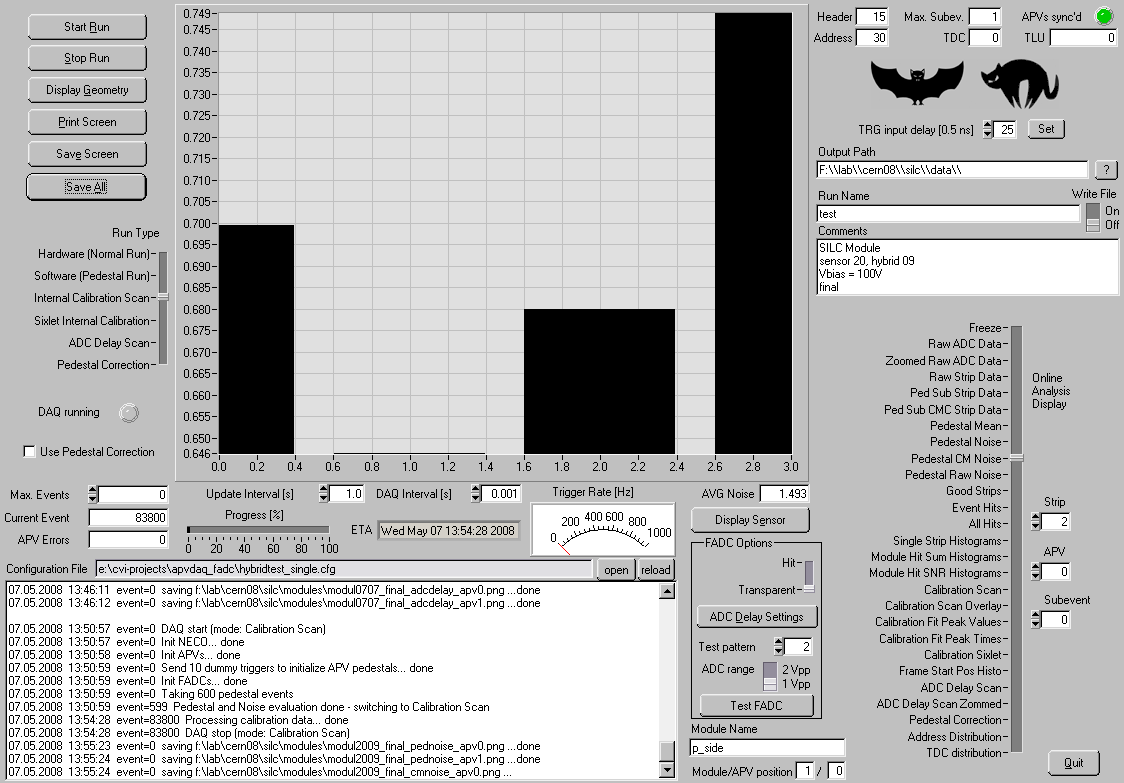

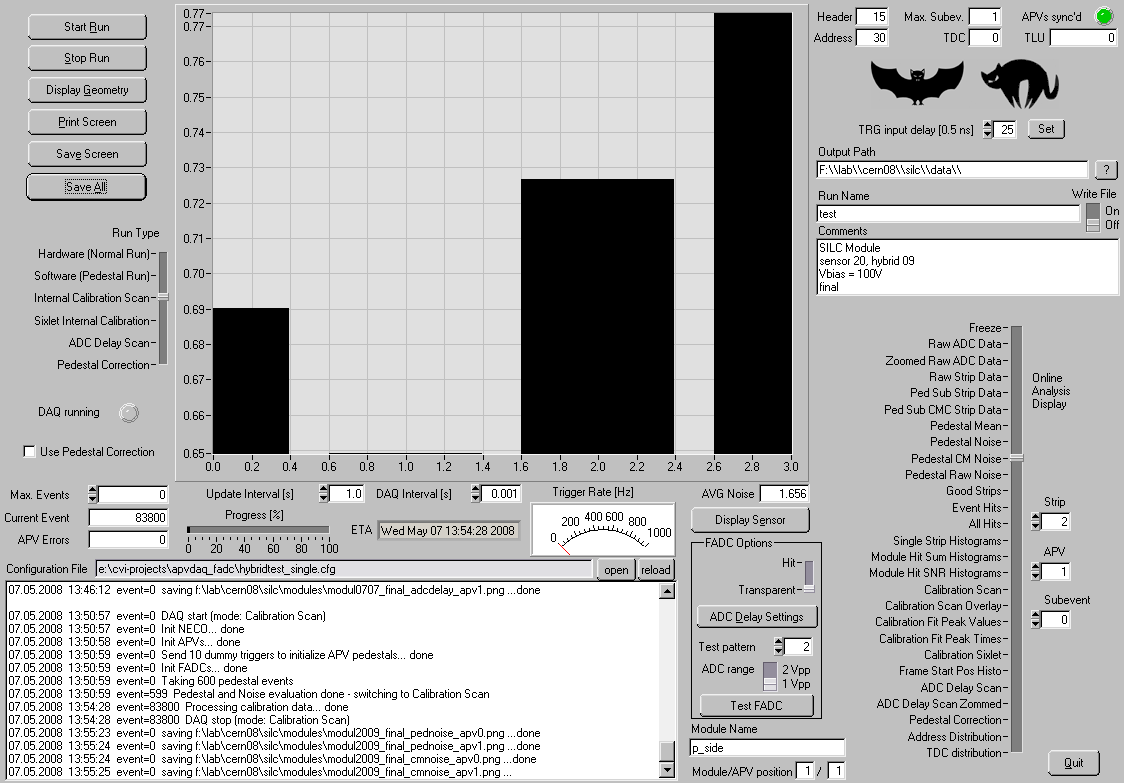

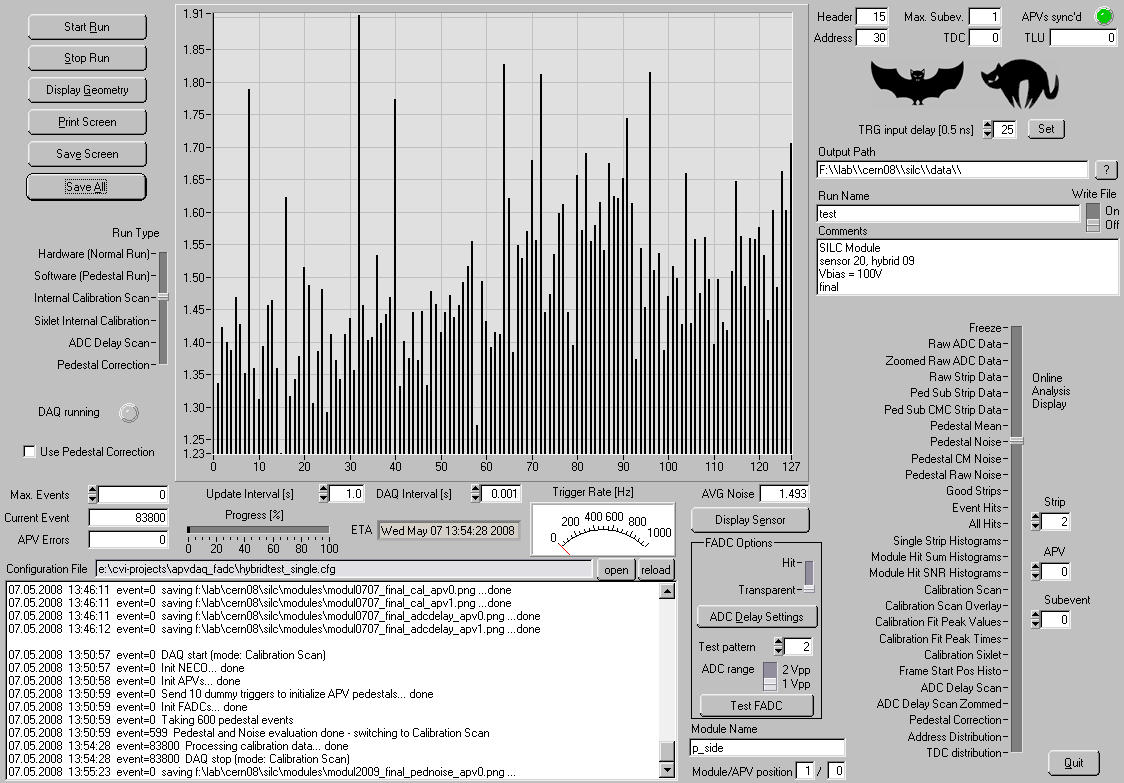

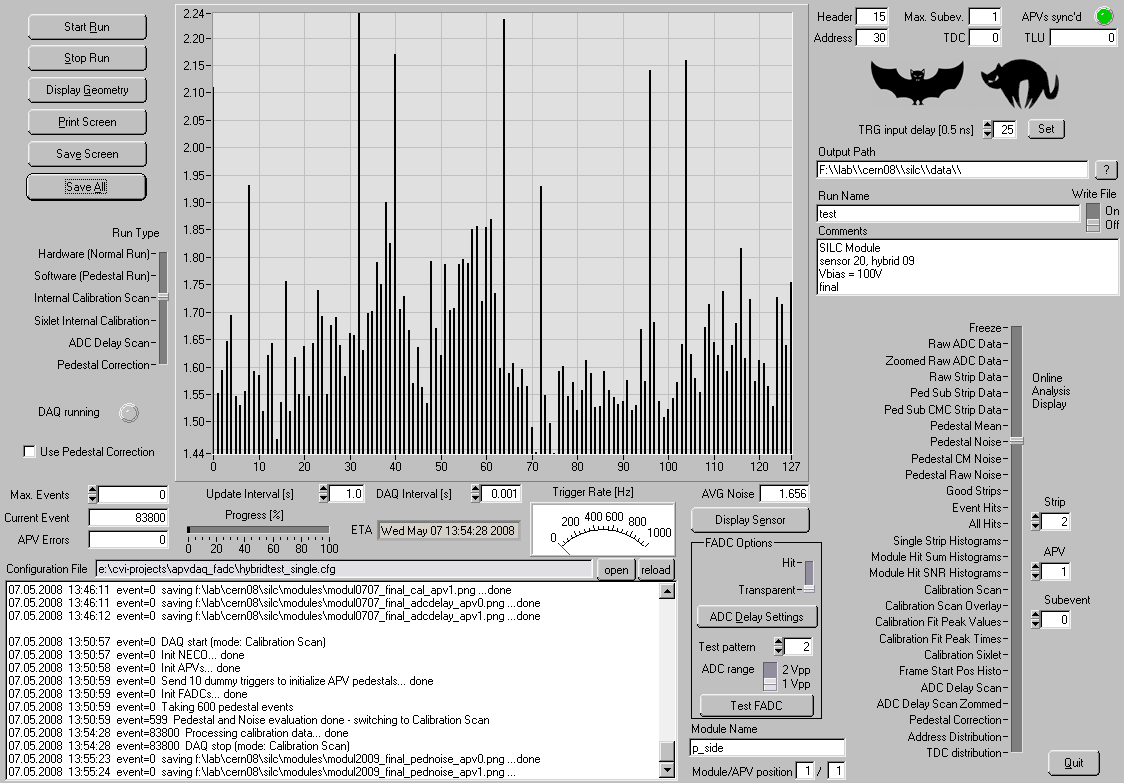

Christian Irmler | SPS Testbeam June08 | module | module 20/09 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100 V) = 25.1 nA

Ibias (200 V) = 31.4 nA |

| Attachment 1: modul2009_1row_cal_apv0.png

|

|

| Attachment 2: modul2009_1row_cal_apv1.png

|

|

| Attachment 3: modul2009_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul2009_1row_cmnoise_apv1.png

|

|

| Attachment 5: modul2009_1row_pednoise_apv0.png

|

|

| Attachment 6: modul2009_1row_pednoise_apv1.png

|

|

| Attachment 7: modul2009_final_cal_apv0.png

|

|

| Attachment 8: modul2009_final_cal_apv1.png

|

|

| Attachment 9: modul2009_final_cmnoise_apv0.png

|

|

| Attachment 10: modul2009_final_cmnoise_apv1.png

|

|

| Attachment 11: modul2009_final_pednoise_apv0.png

|

|

| Attachment 12: modul2009_final_pednoise_apv1.png

|

|

|

|

7

|

Wed May 7 16:12:58 2008 |

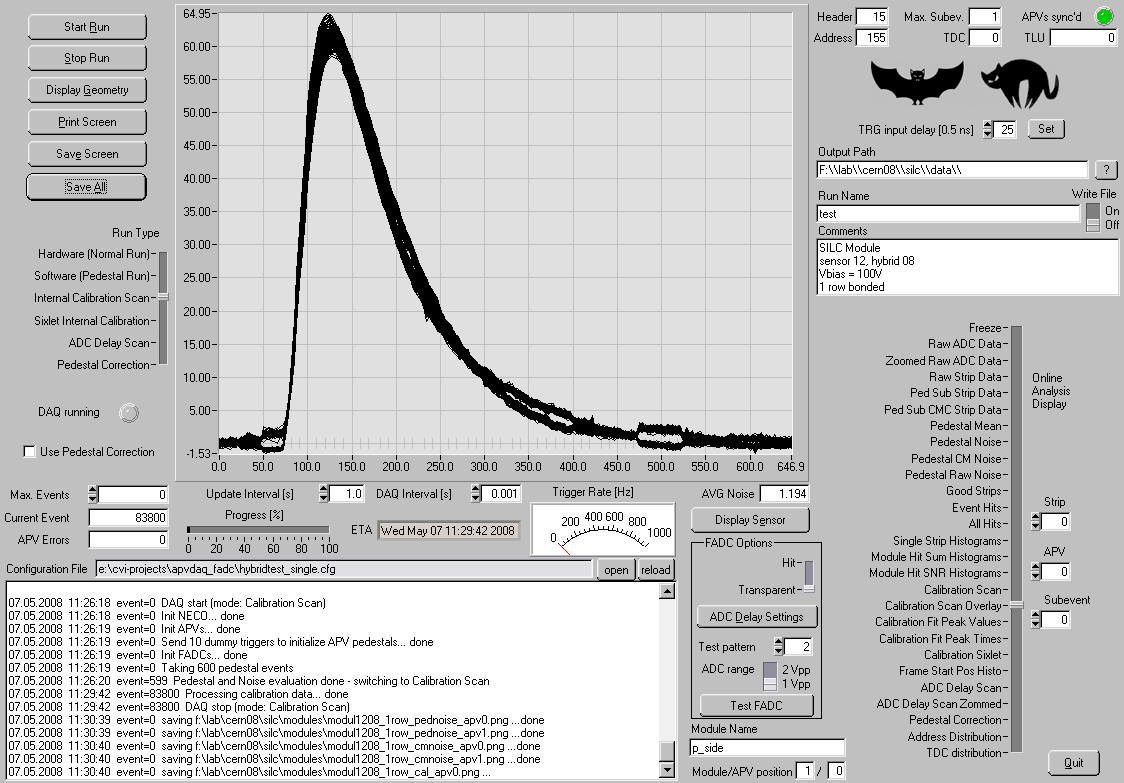

Christian Irmler | SPS Testbeam June08 | module | module 12/08 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100 V) = 22.2 nA

Ibias (200 V) = 26.5 nA |

| Attachment 1: modul1208_1row_cal_apv0.png

|

|

| Attachment 2: modul0707_1row_cal_apv1.png

|

|

| Attachment 3: modul0707_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul0707_1row_cmnoise_apv1.png

|

|

| Attachment 5: modul0707_1row_pednoise_apv0.png

|

|

| Attachment 6: modul0707_1row_pednoise_apv1.png

|

|

| Attachment 7: modul0707_final_cal_apv0.png

|

|

| Attachment 8: modul0707_final_cal_apv1.png

|

|

| Attachment 9: modul0707_final_cmnoise_apv0.png

|

|

| Attachment 10: modul0707_final_cmnoise_apv1.png

|

|

| Attachment 11: modul0707_final_pednoise_apv0.png

|

|

| Attachment 12: modul0707_final_pednoise_apv1.png

|

|

|

|

6

|

Wed May 7 15:24:49 2008 |

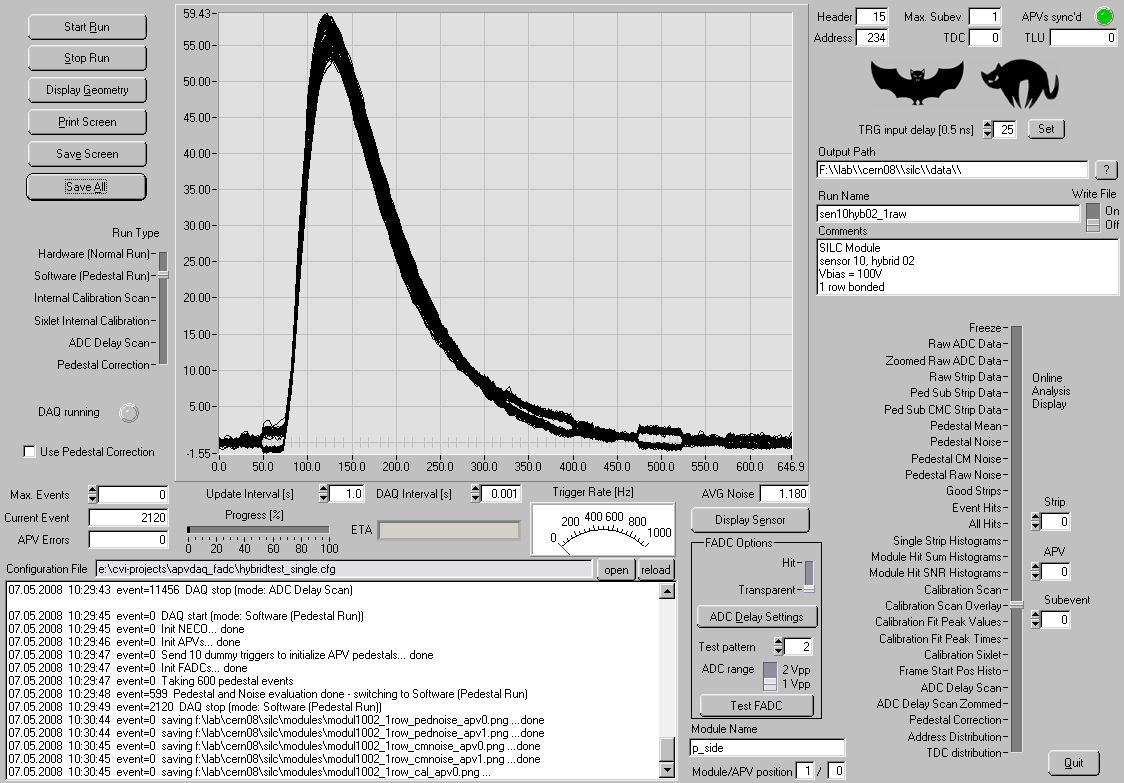

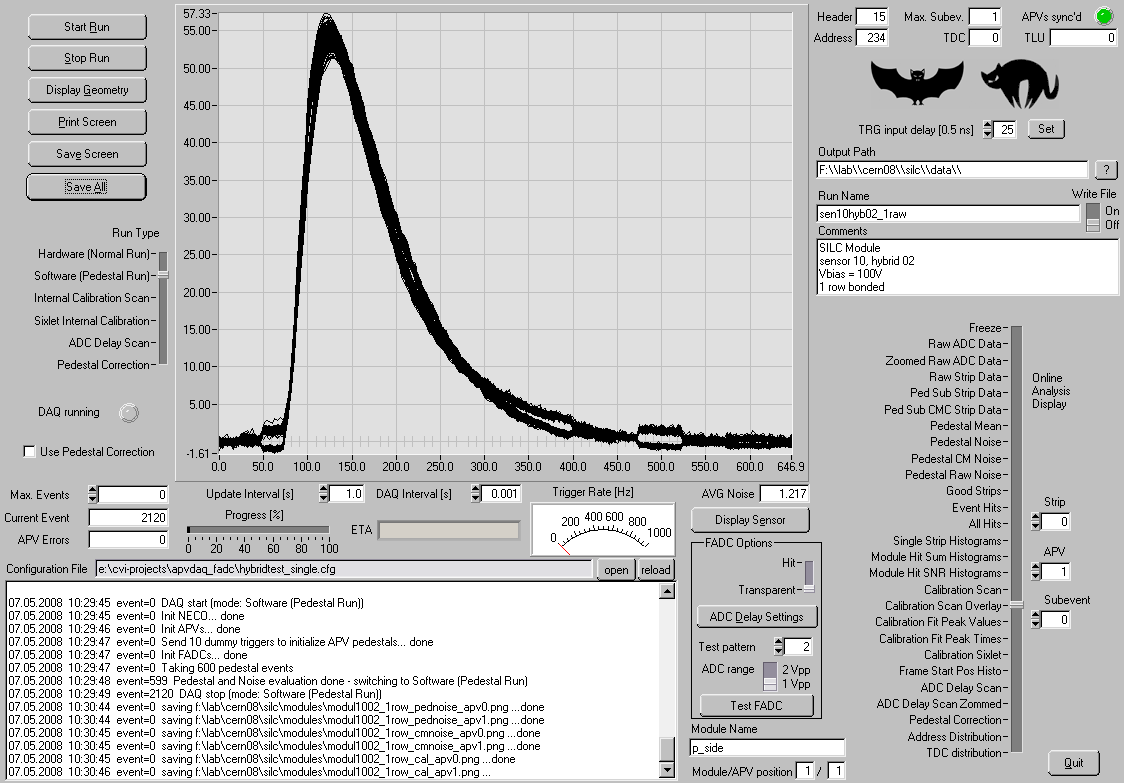

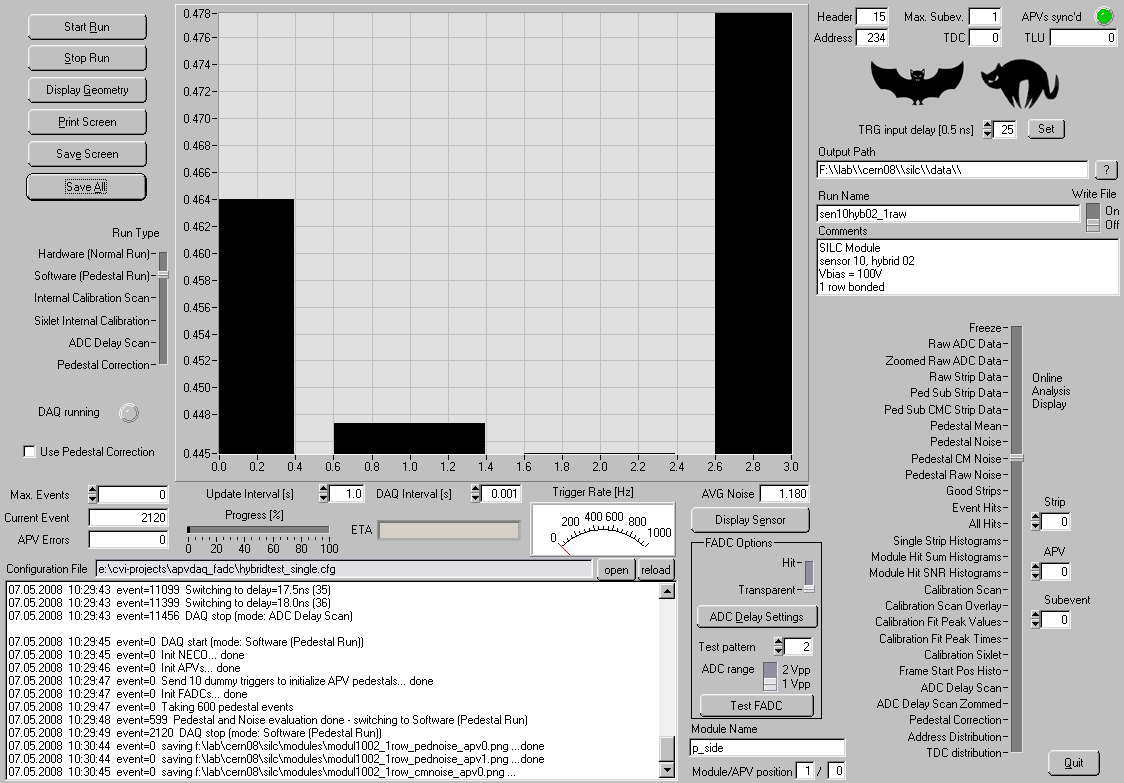

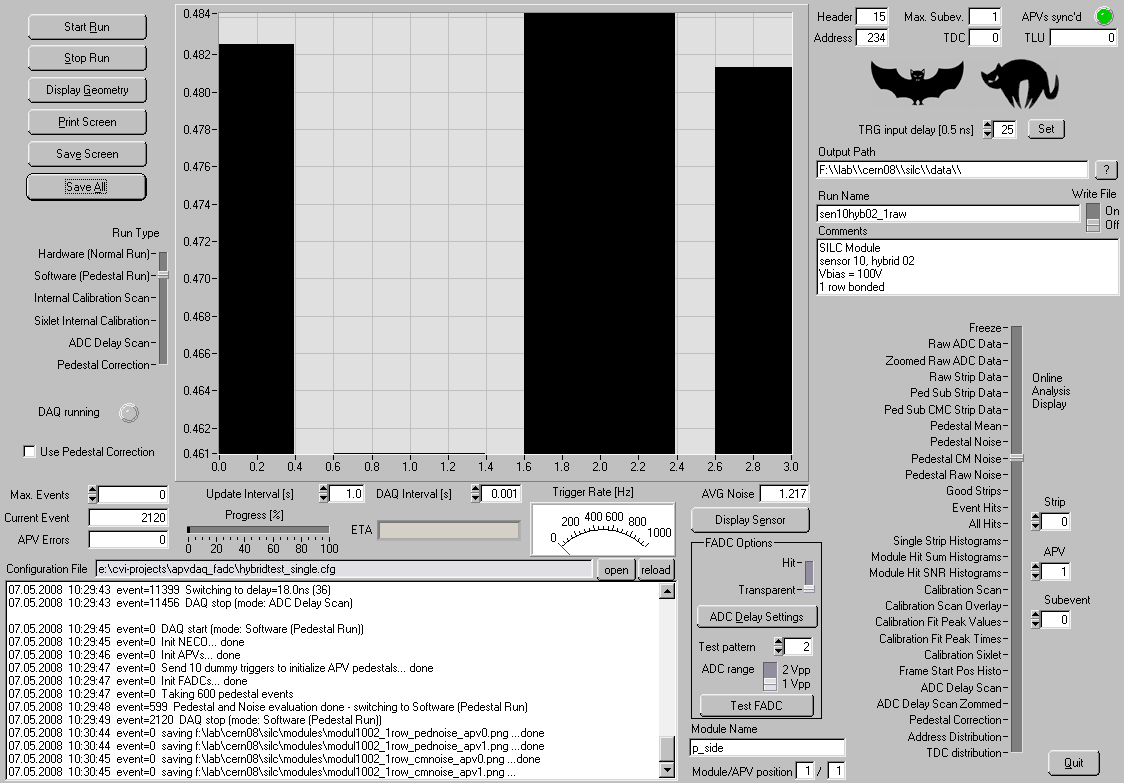

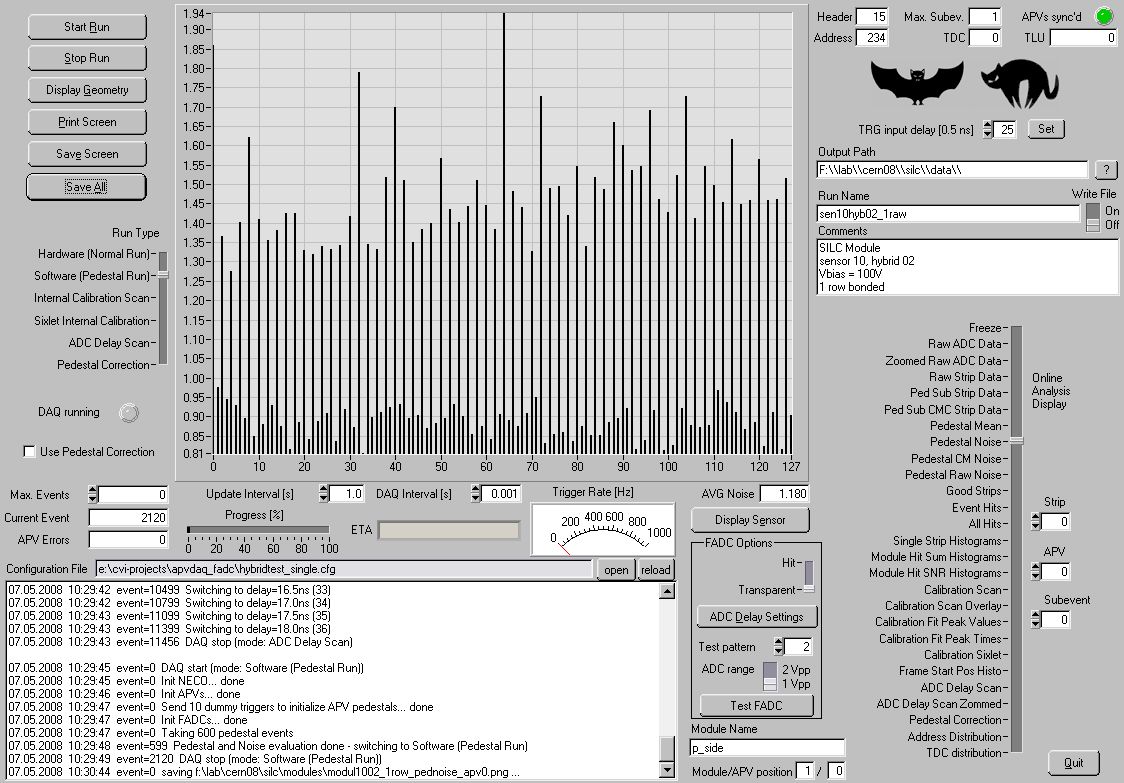

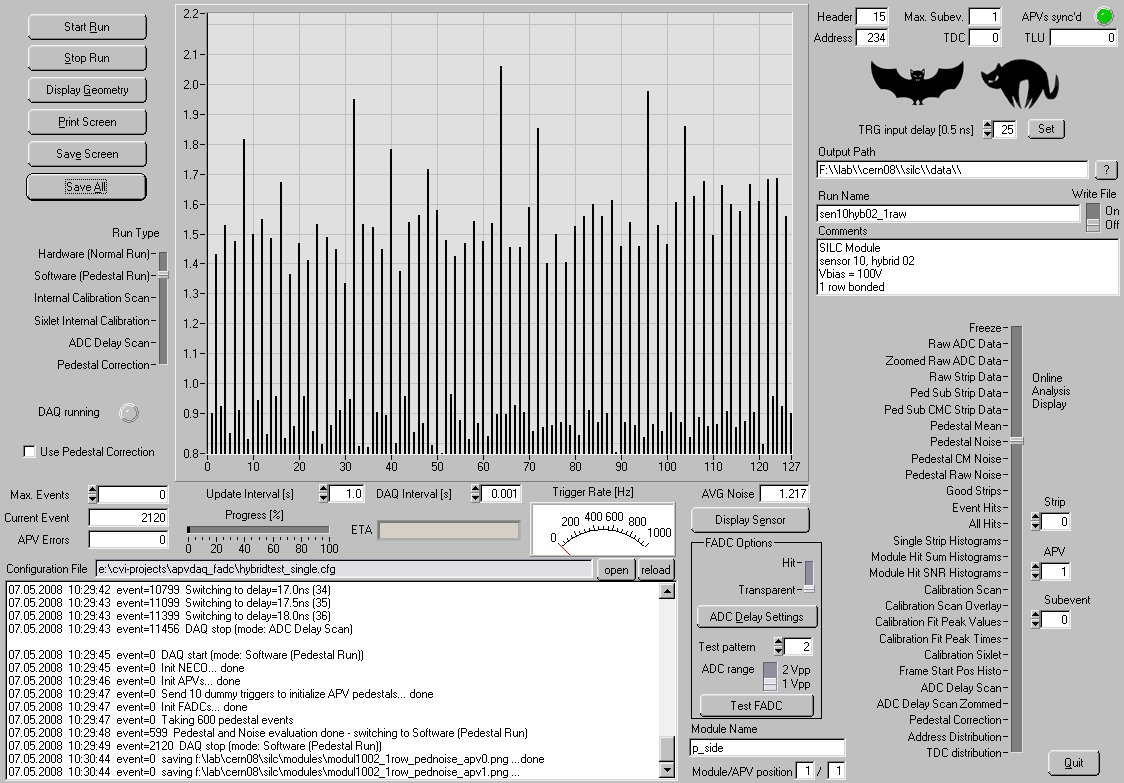

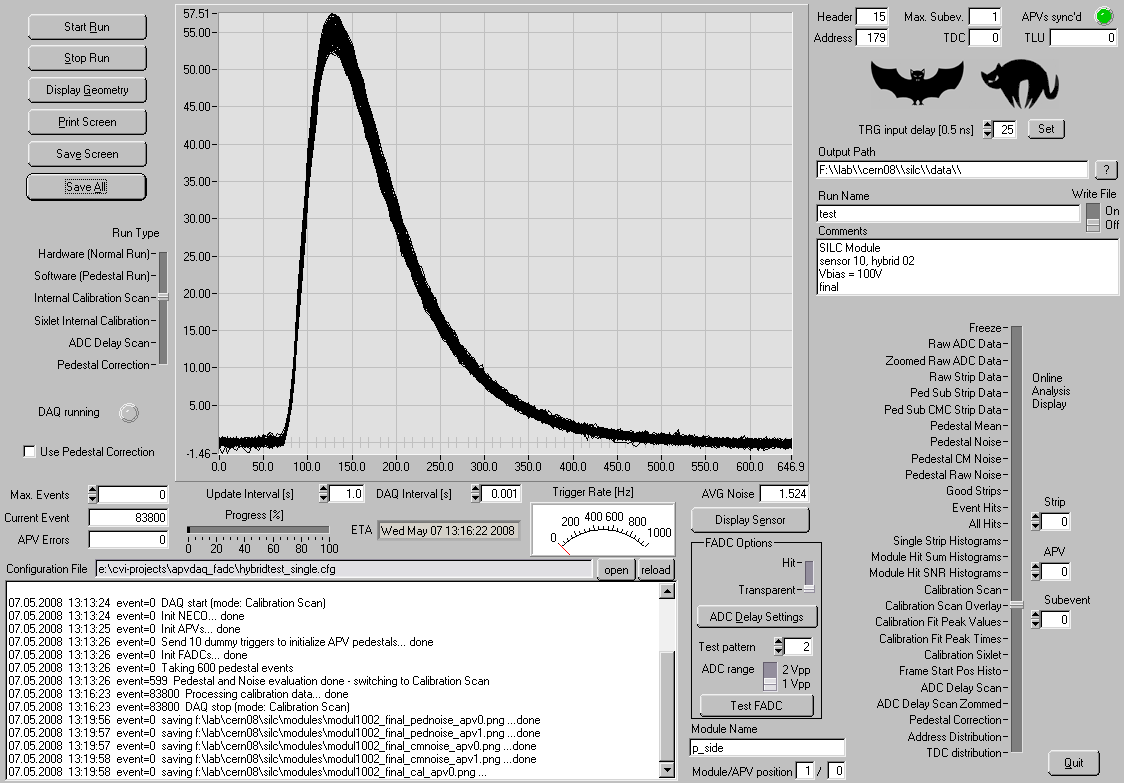

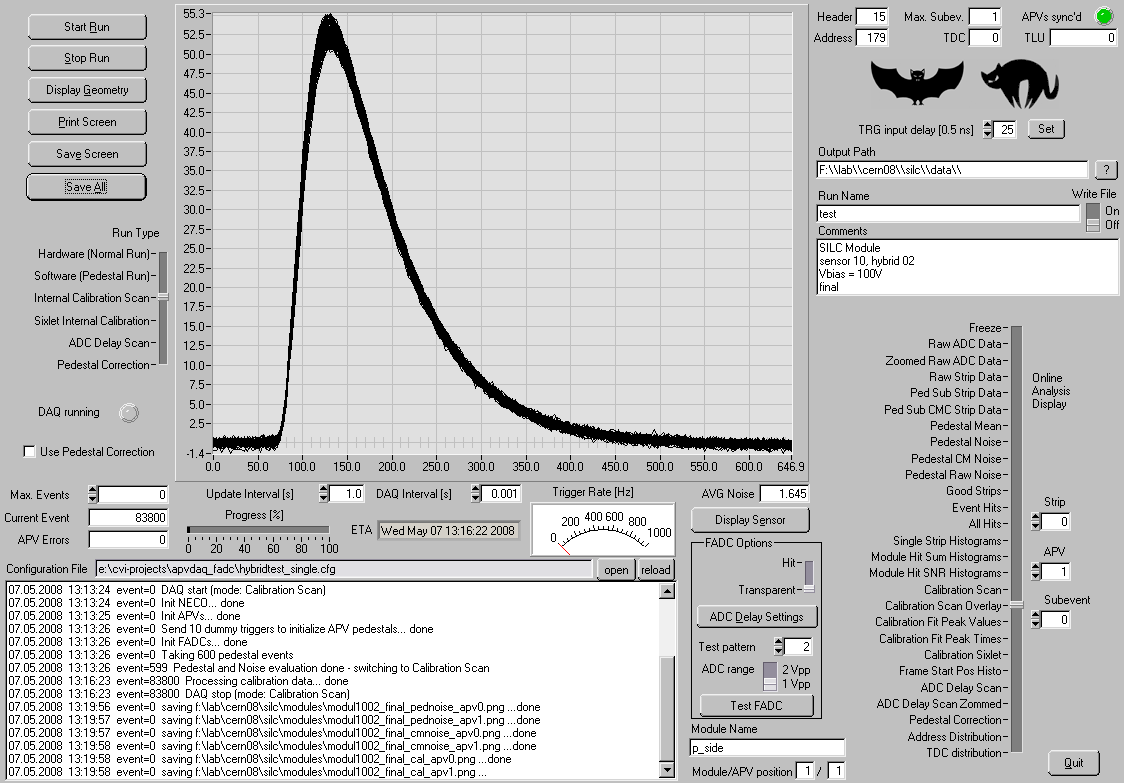

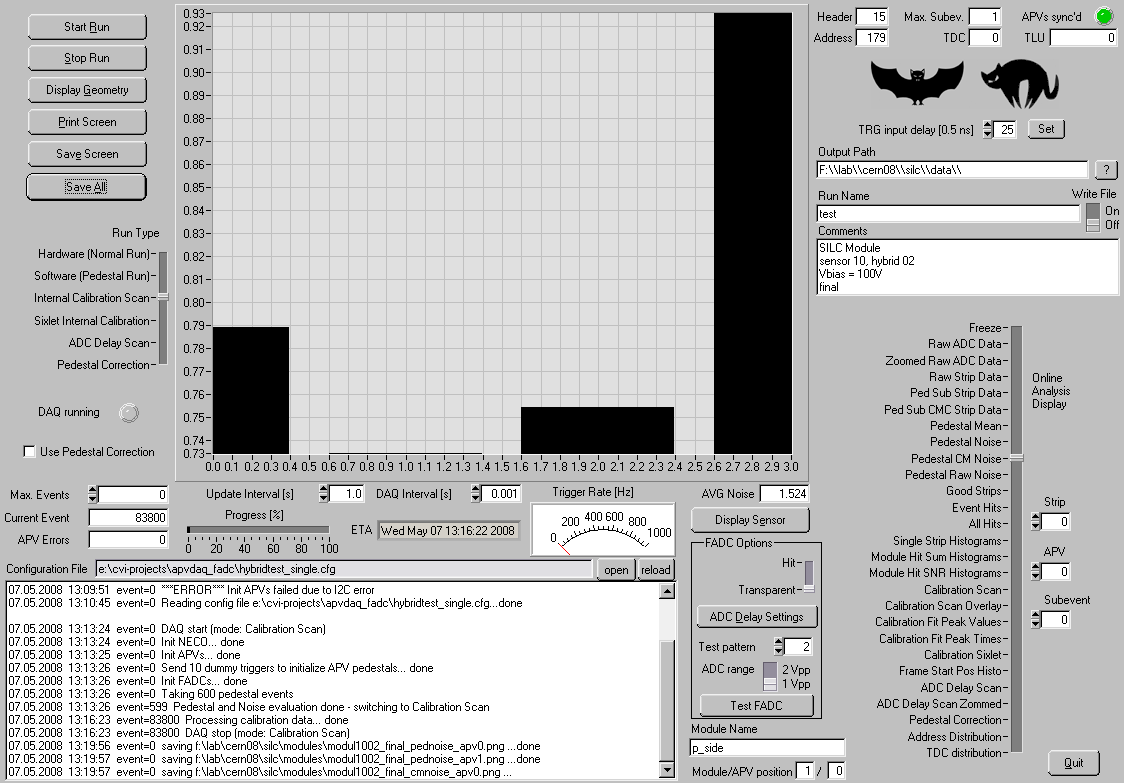

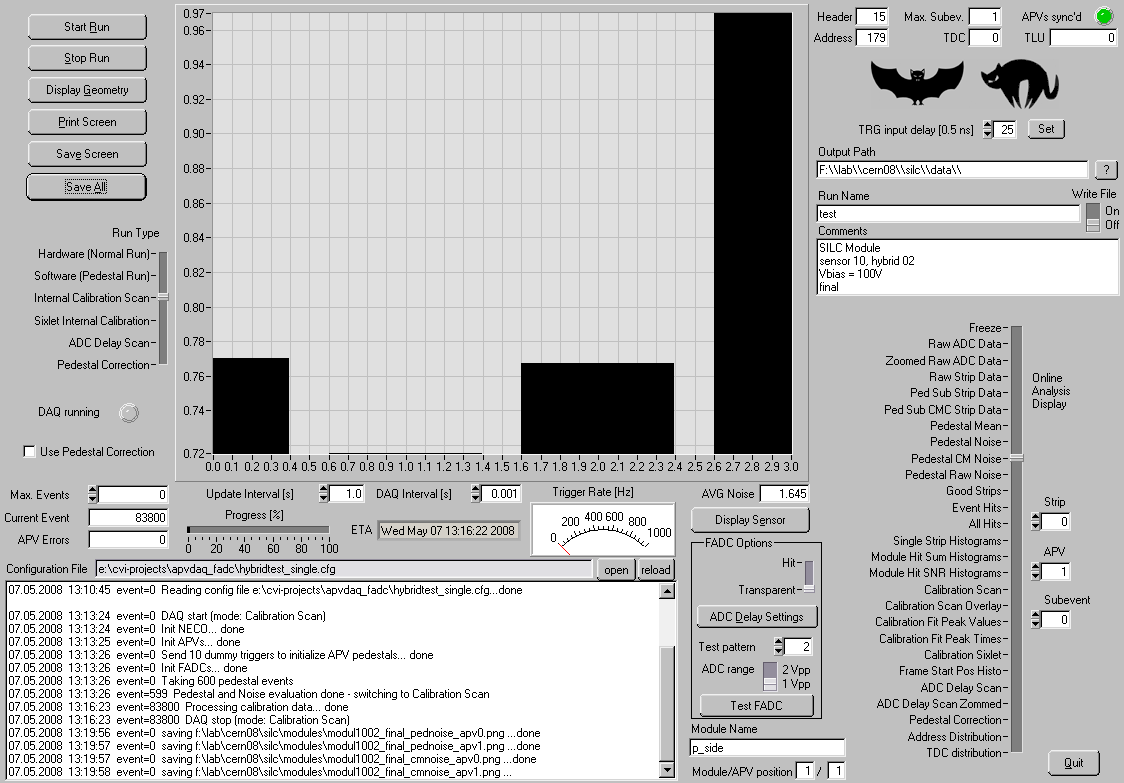

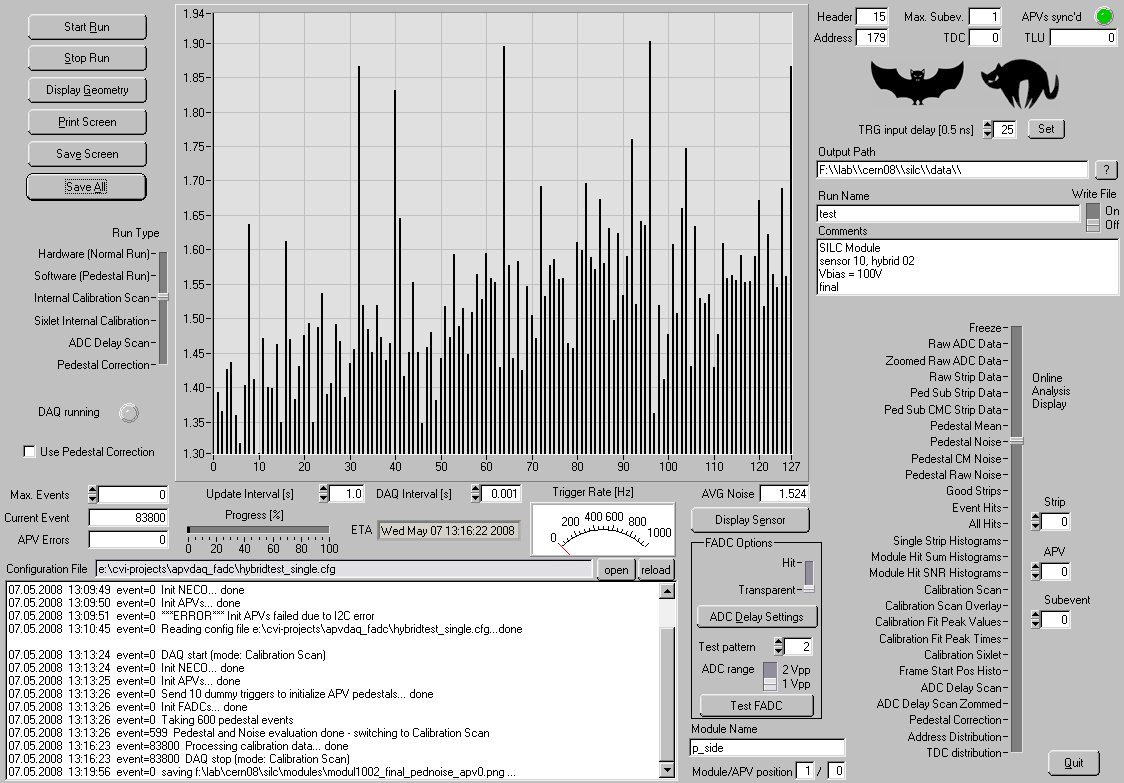

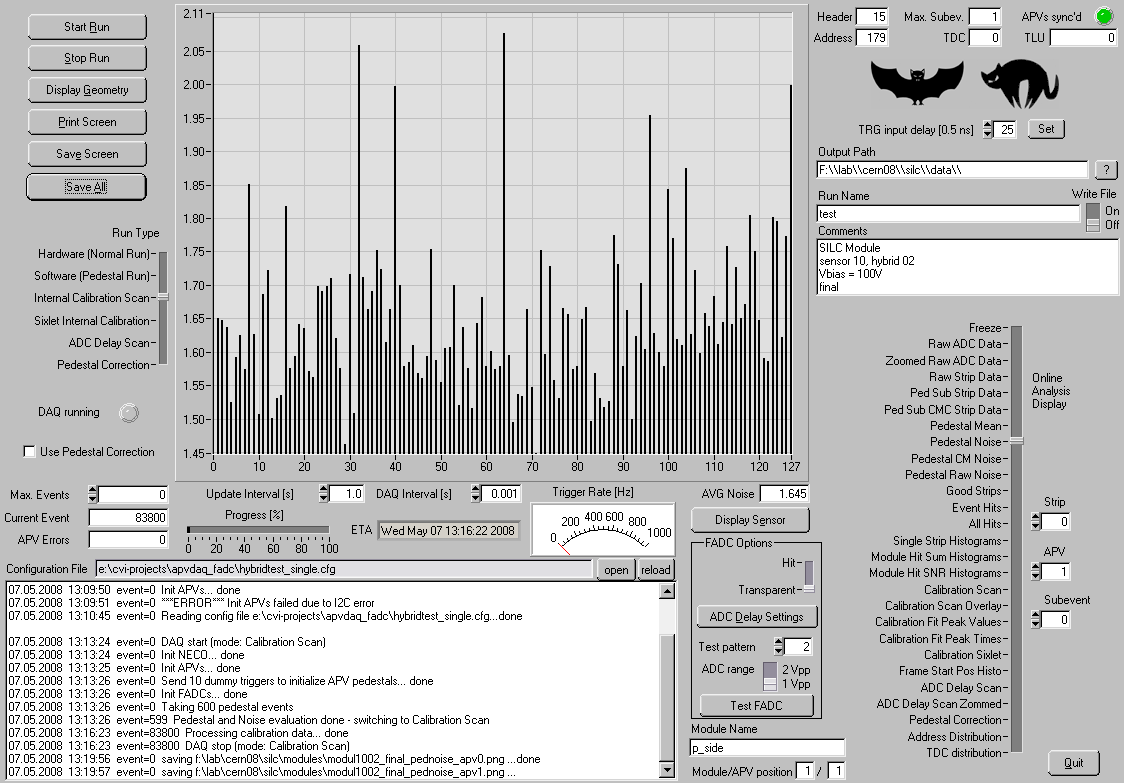

Christian Irmler | SPS Testbeam June08 | module | module 10/02 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100V) = 19.1 nA

Ibias (200V) = 23.7 nA |

| Attachment 1: modul1002_1row_cal_apv0.png

|

|

| Attachment 2: modul1002_1row_cal_apv1.png

|

|

| Attachment 3: modul1002_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul1002_1row_cmnoise_apv1.png

|

|

| Attachment 5: modul1002_1row_pednoise_apv0.png

|

|

| Attachment 6: modul1002_1row_pednoise_apv1.png

|

|

| Attachment 7: modul1002_final_cal_apv0.png

|

|

| Attachment 8: modul1002_final_cal_apv1.png

|

|

| Attachment 9: modul1002_final_cmnoise_apv0.png

|

|

| Attachment 10: modul1002_final_cmnoise_apv1.png

|

|

| Attachment 11: modul1002_final_pednoise_apv0.png

|

|

| Attachment 12: modul1002_final_pednoise_apv1.png

|

|

|

|

8

|

Wed May 7 15:40:07 2008 |

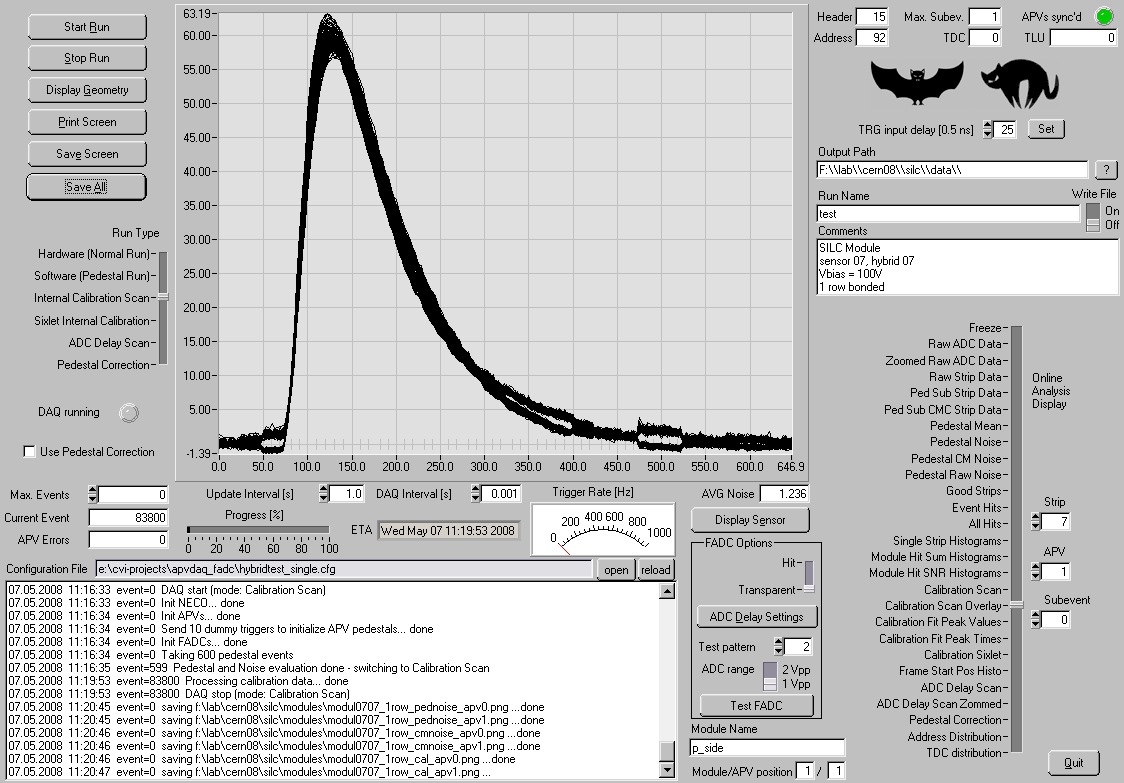

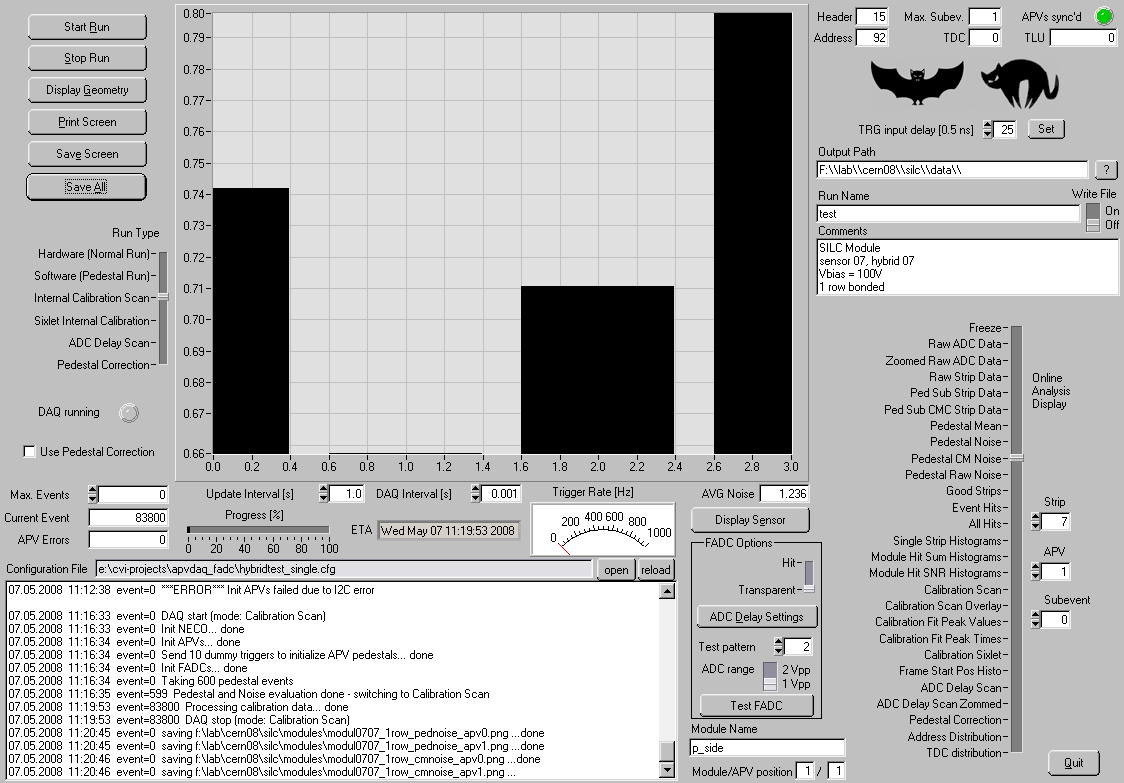

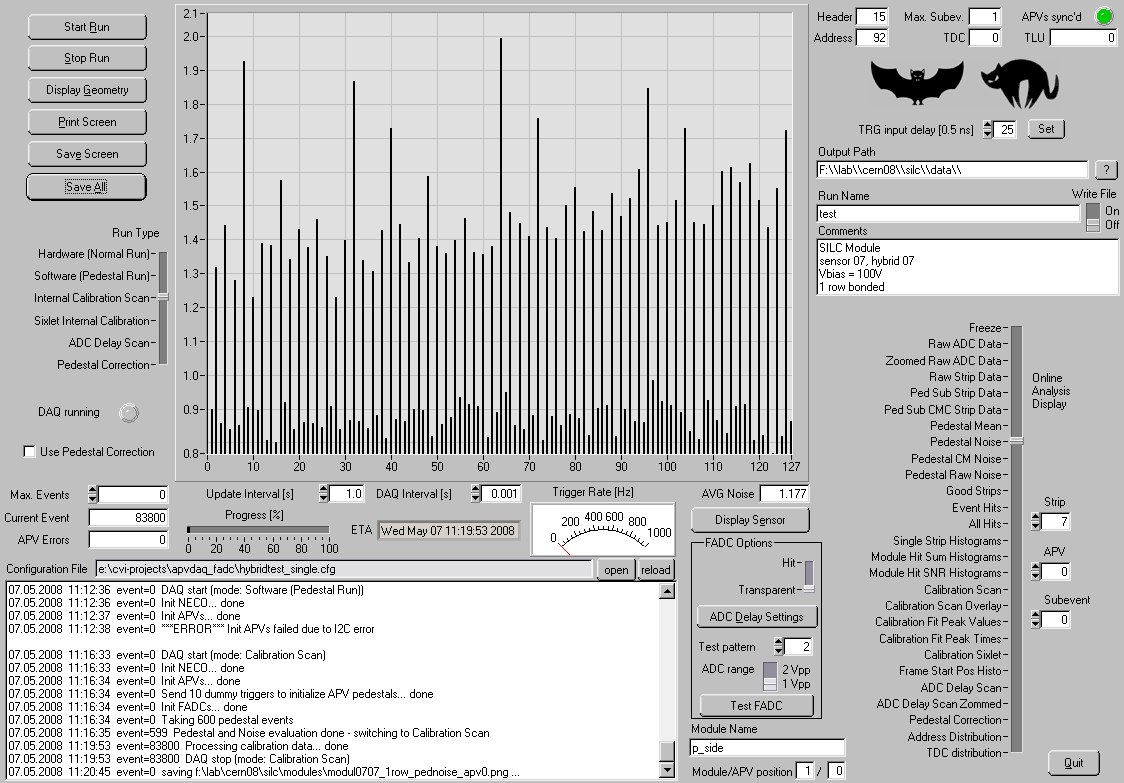

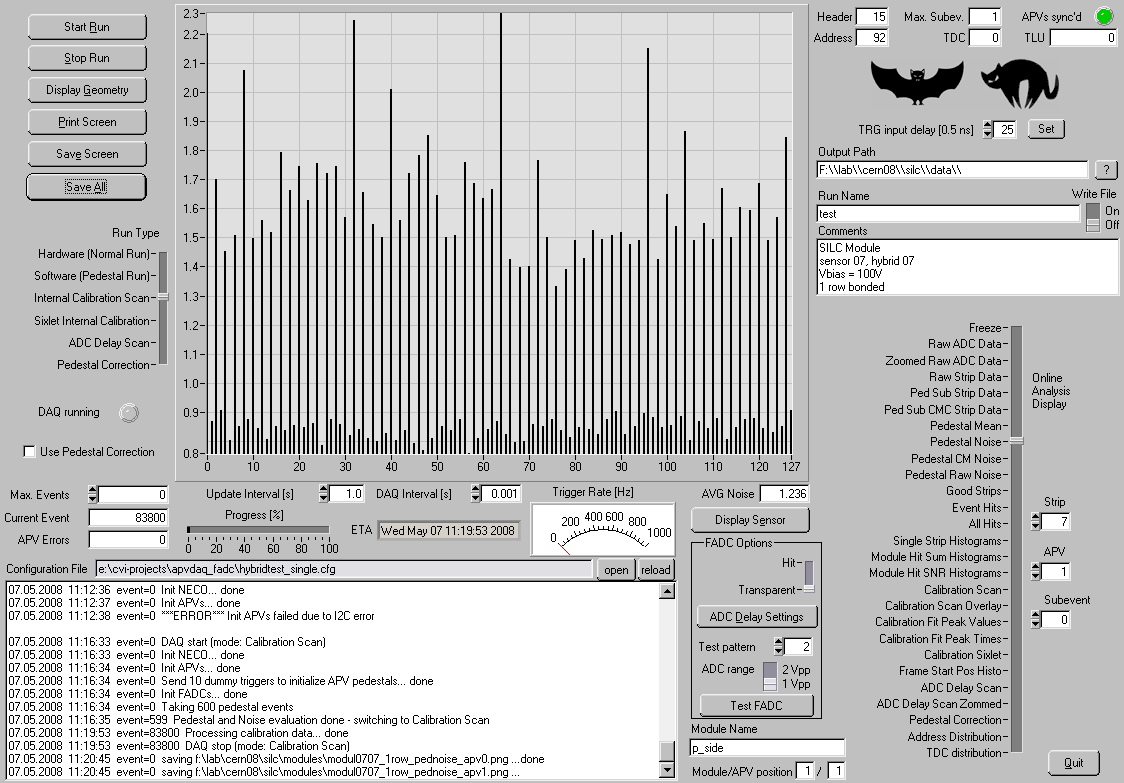

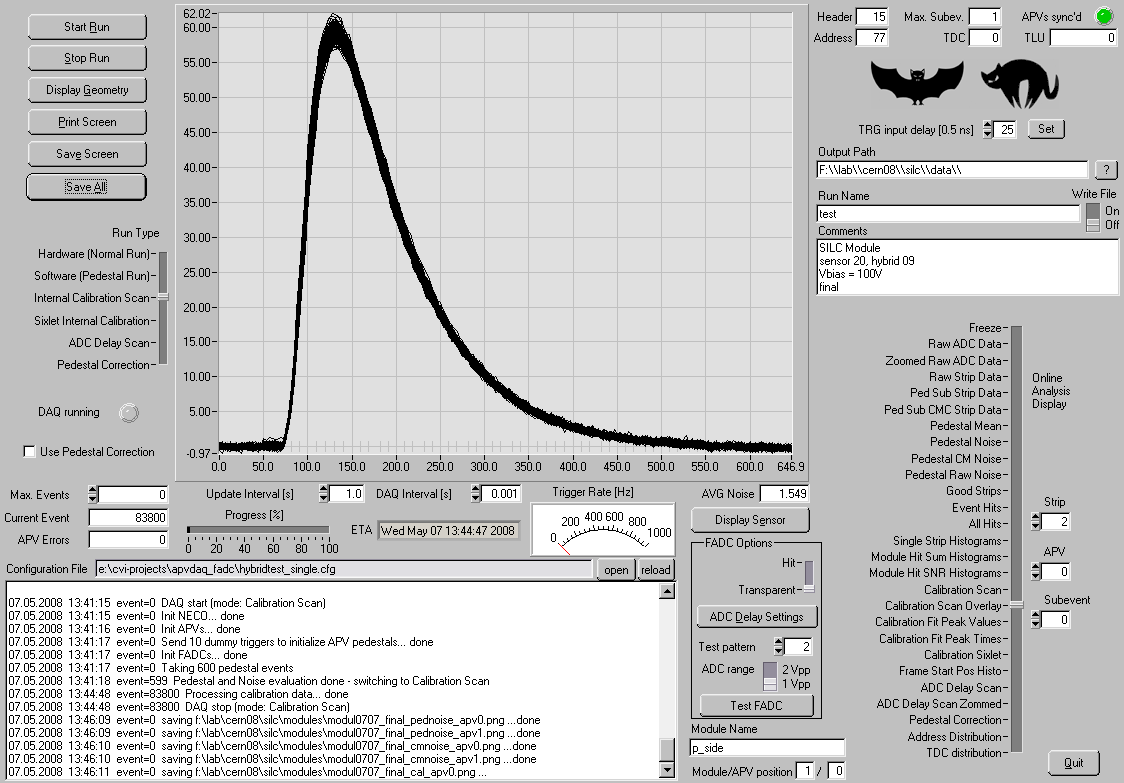

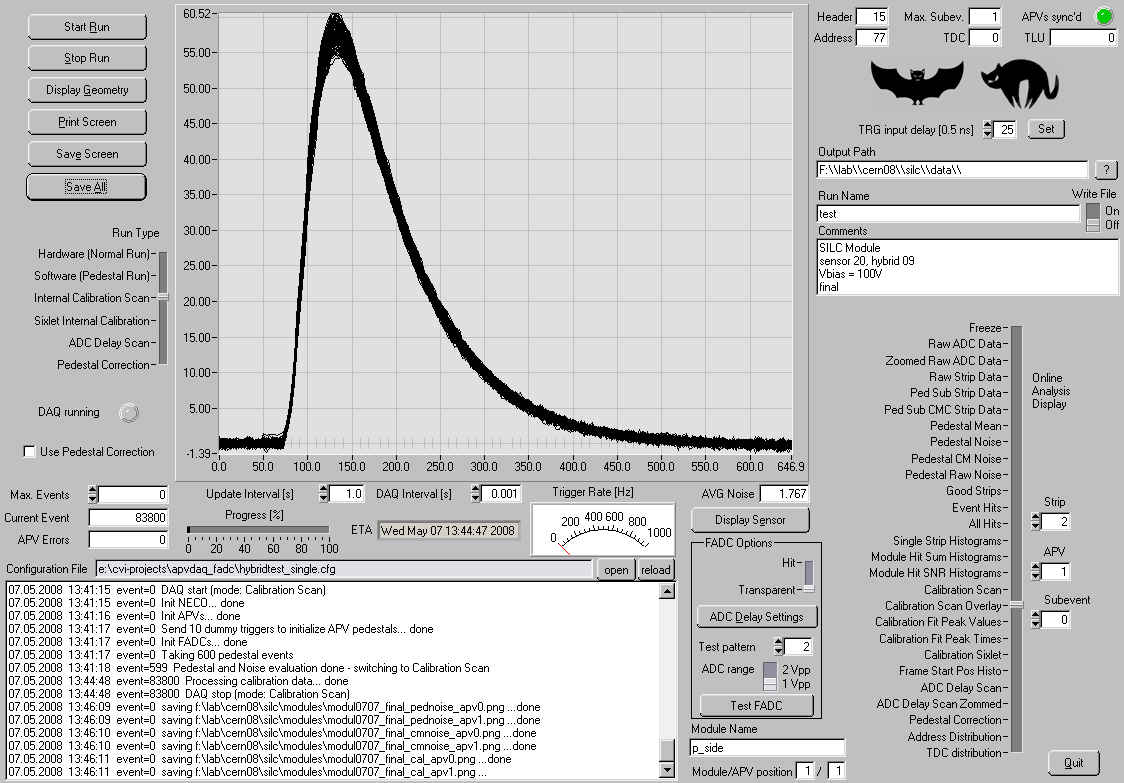

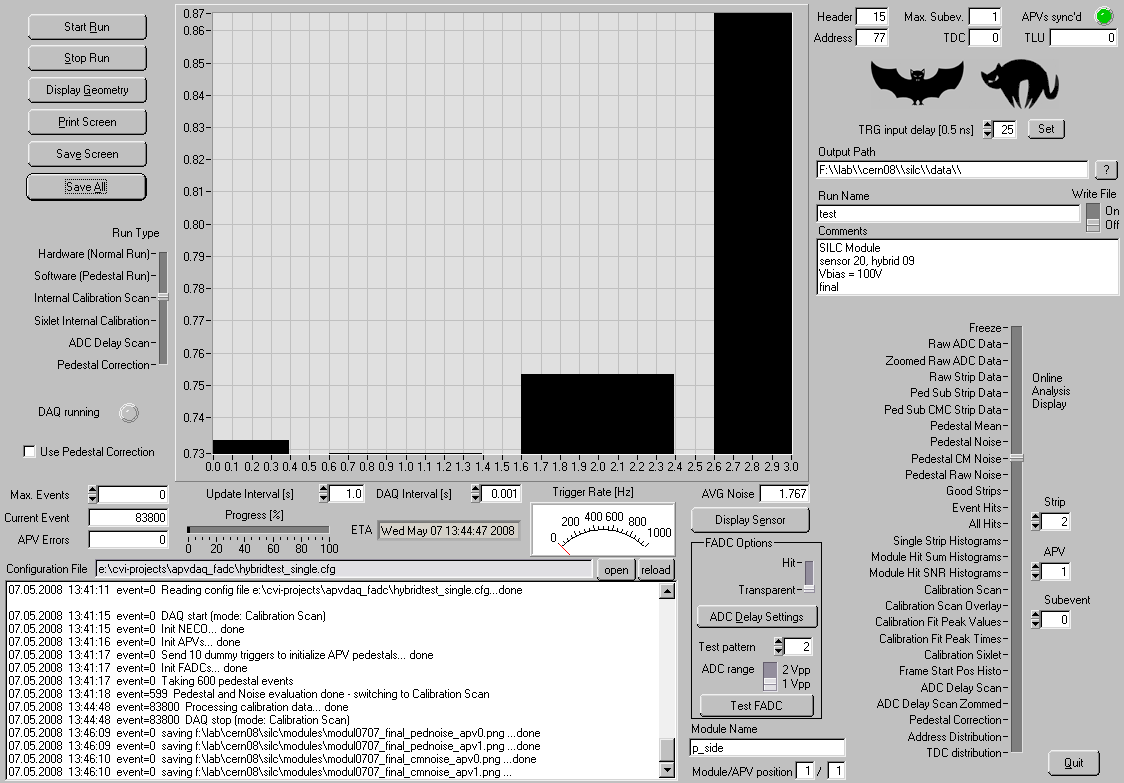

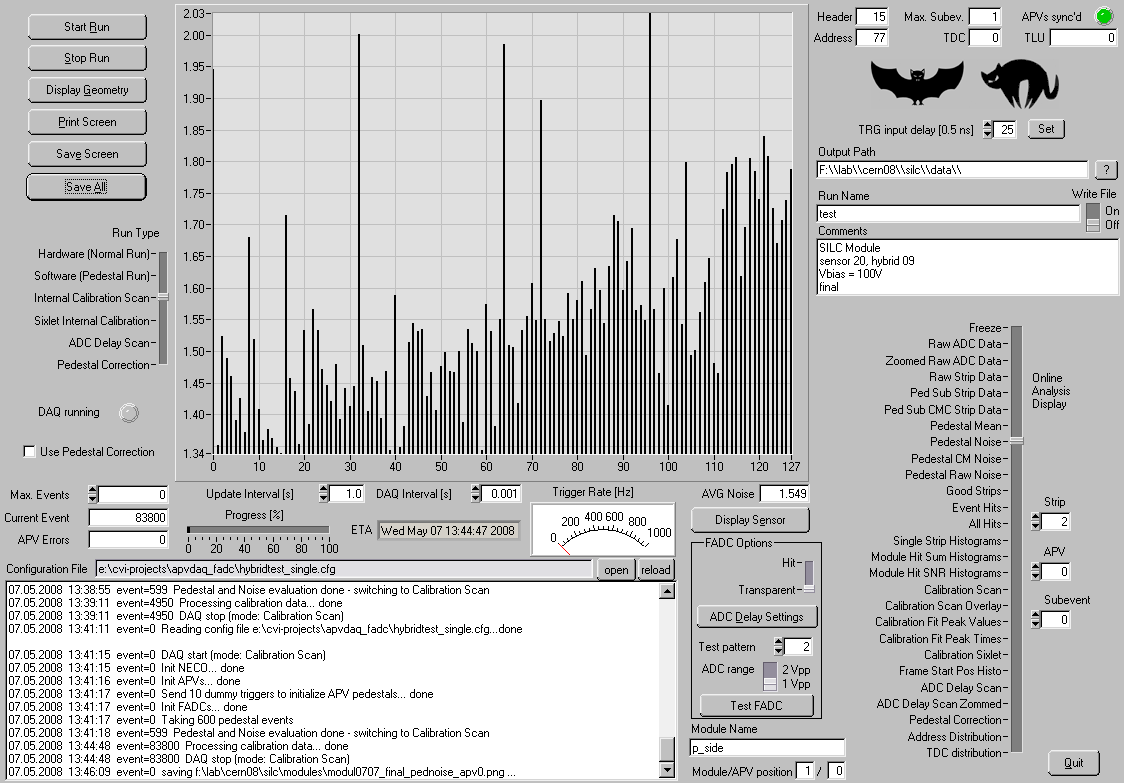

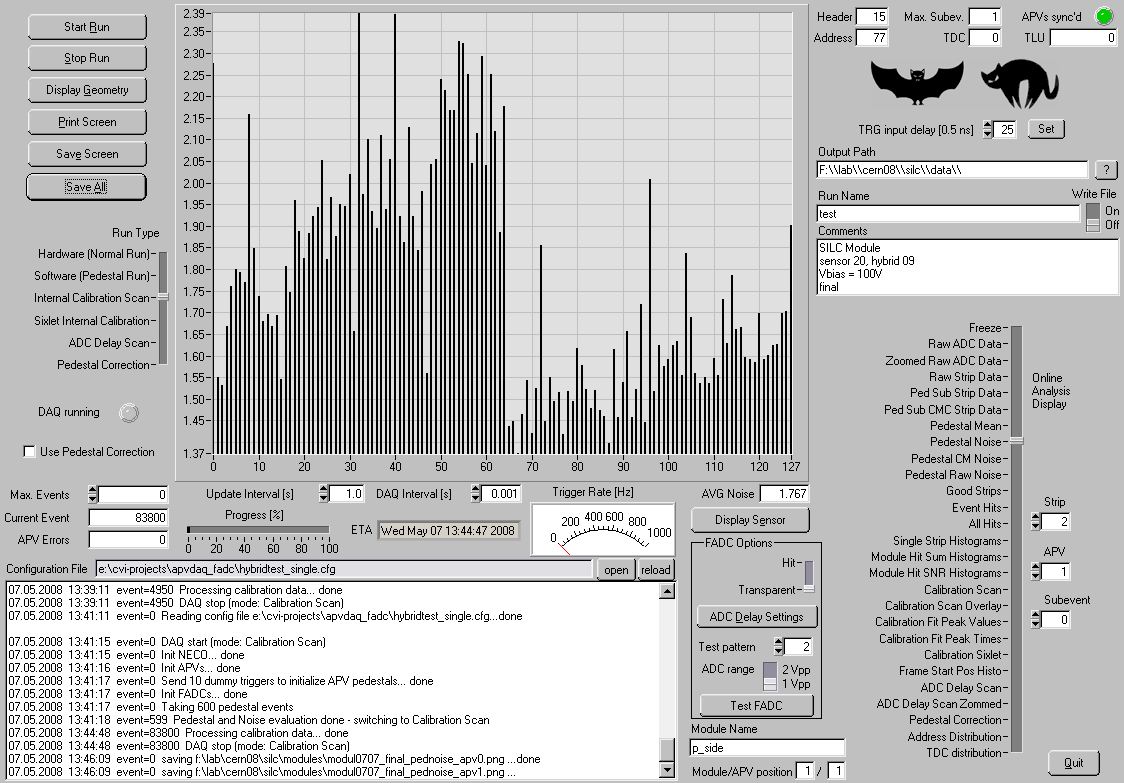

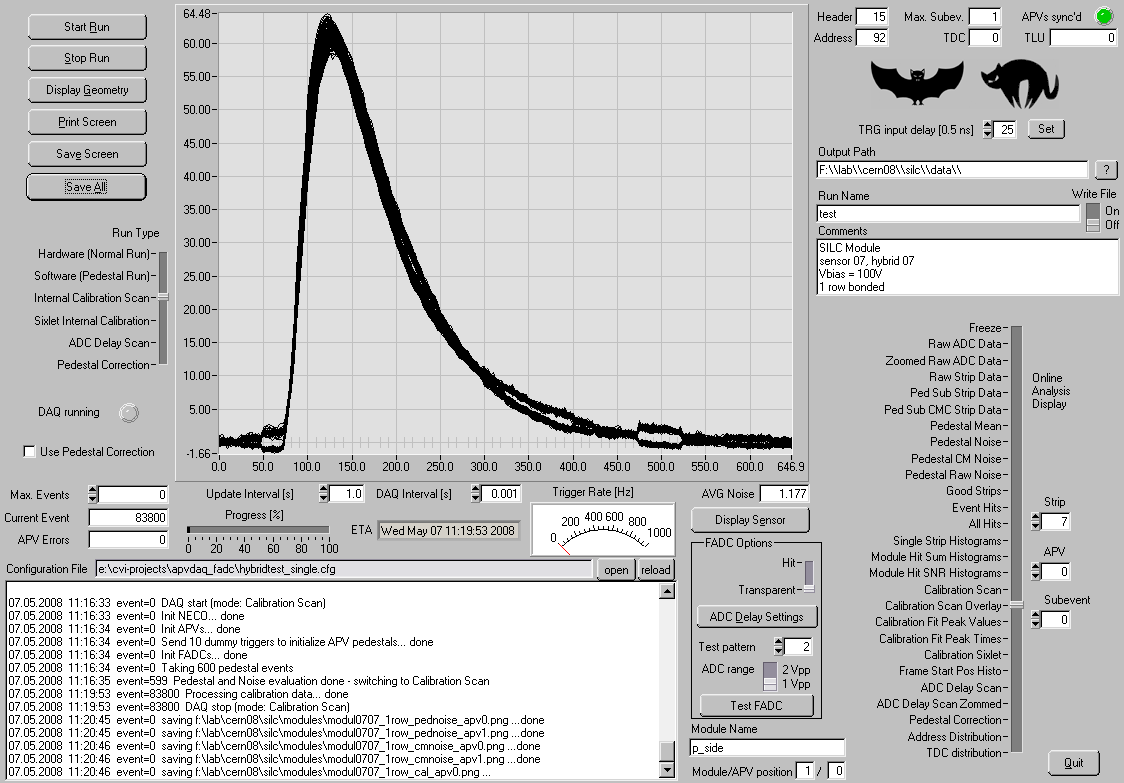

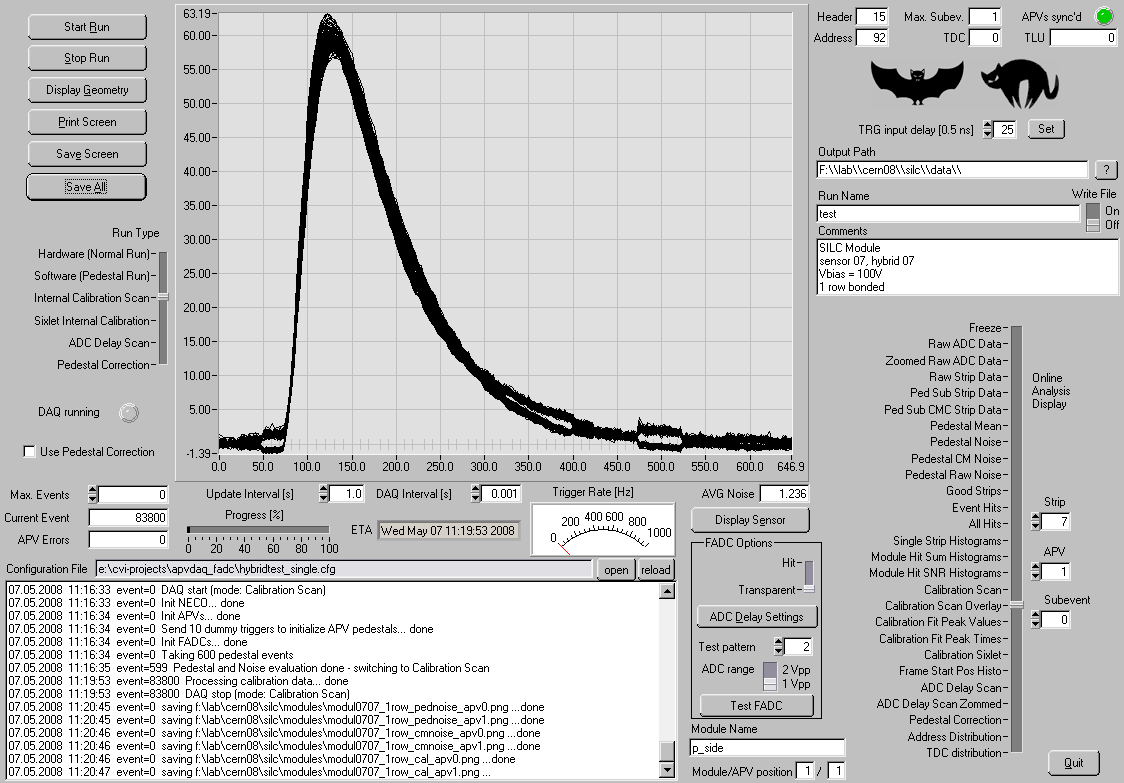

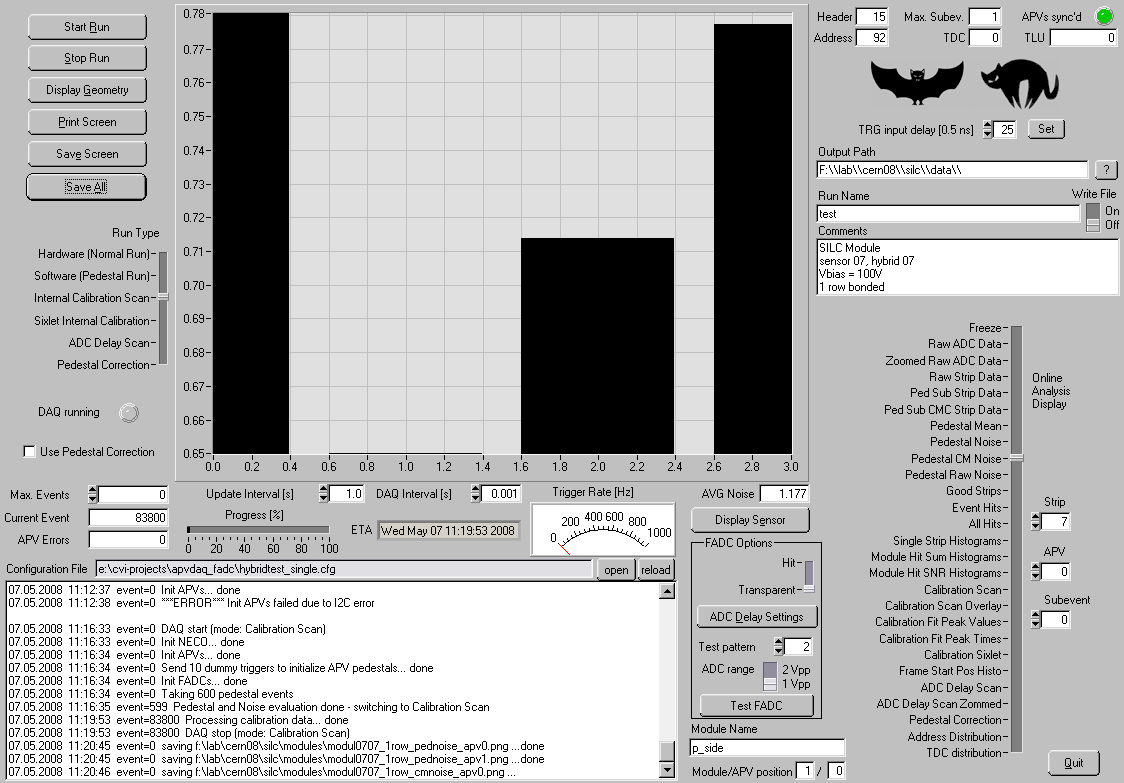

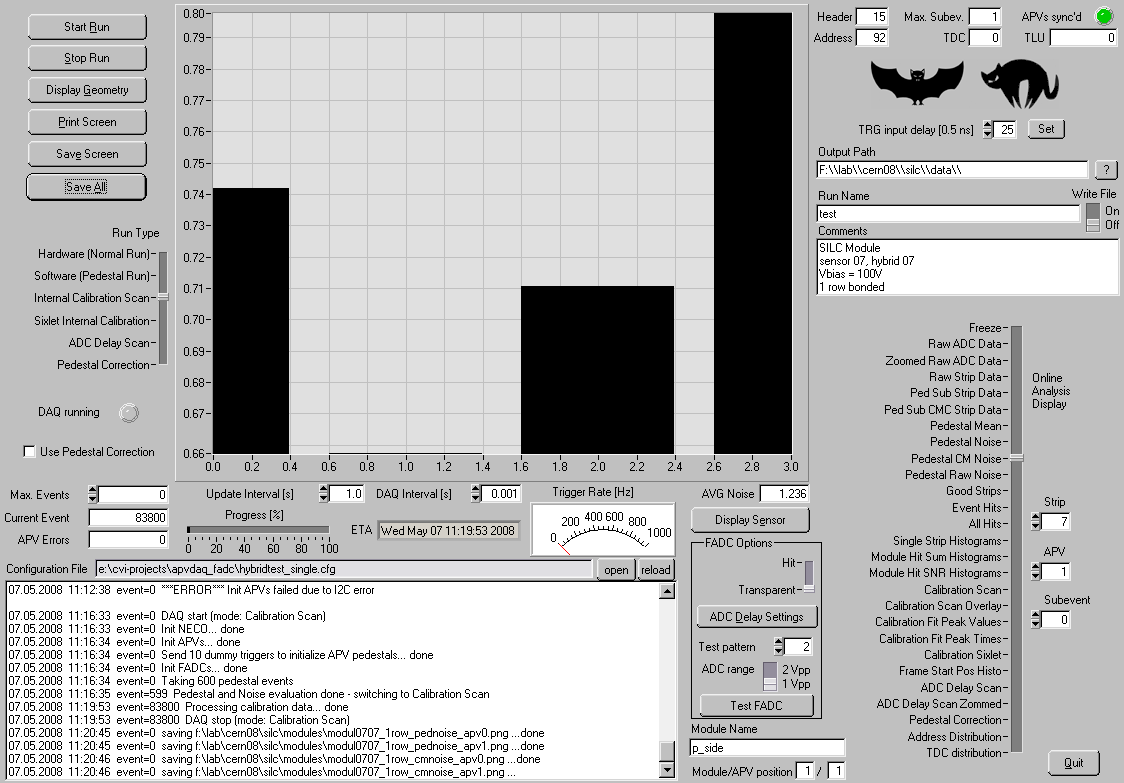

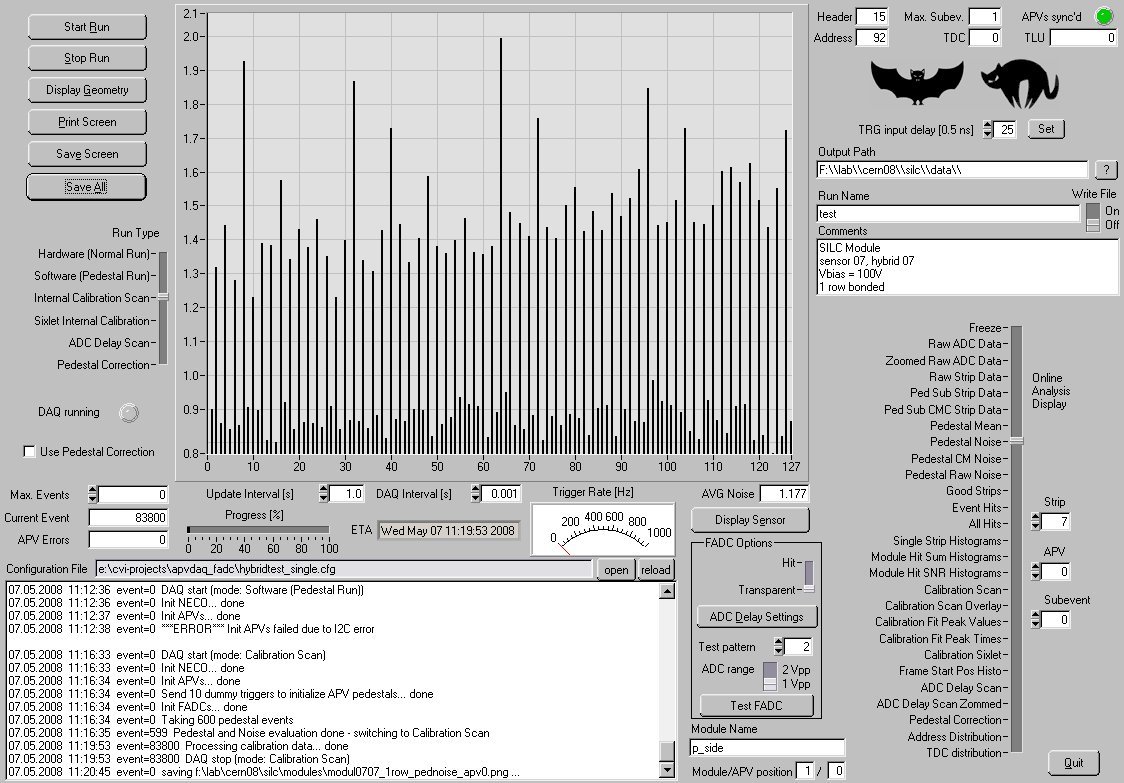

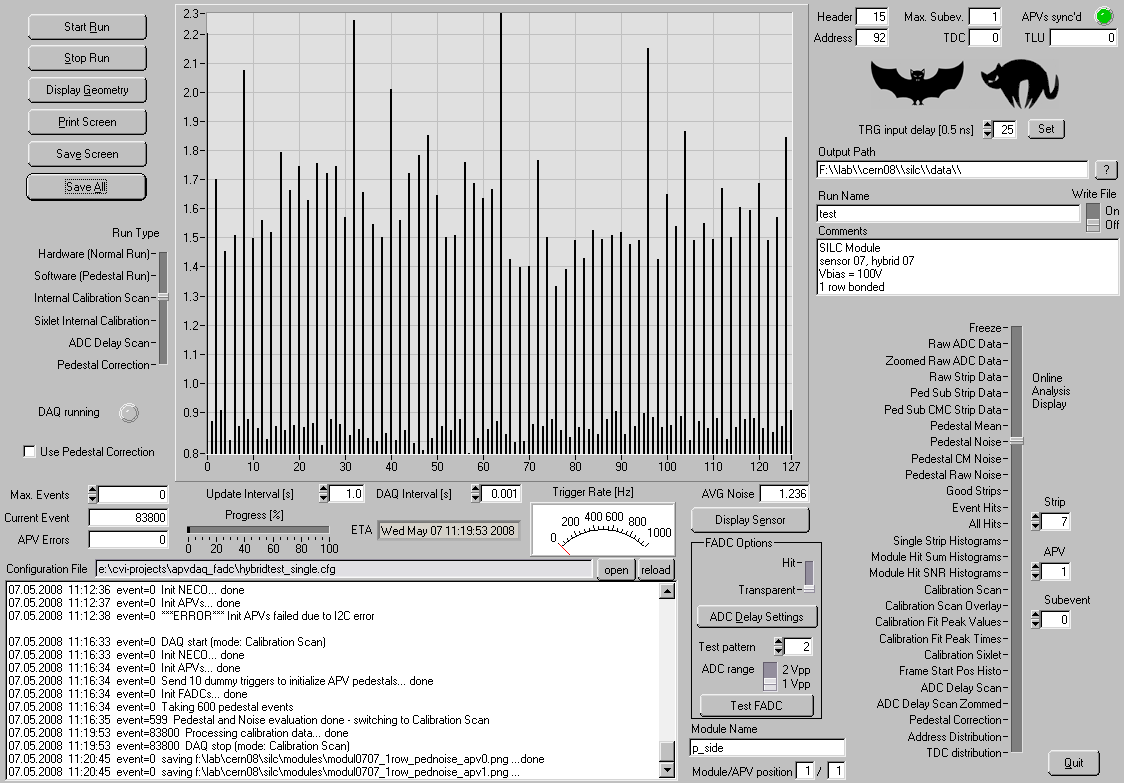

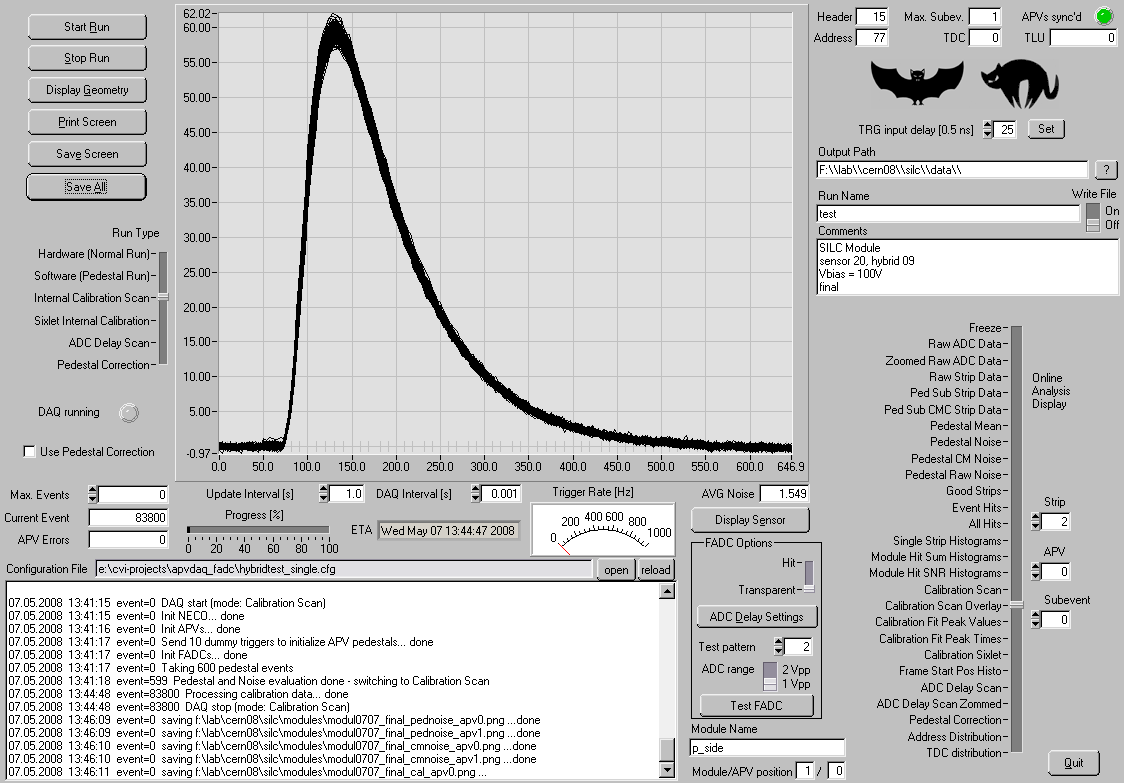

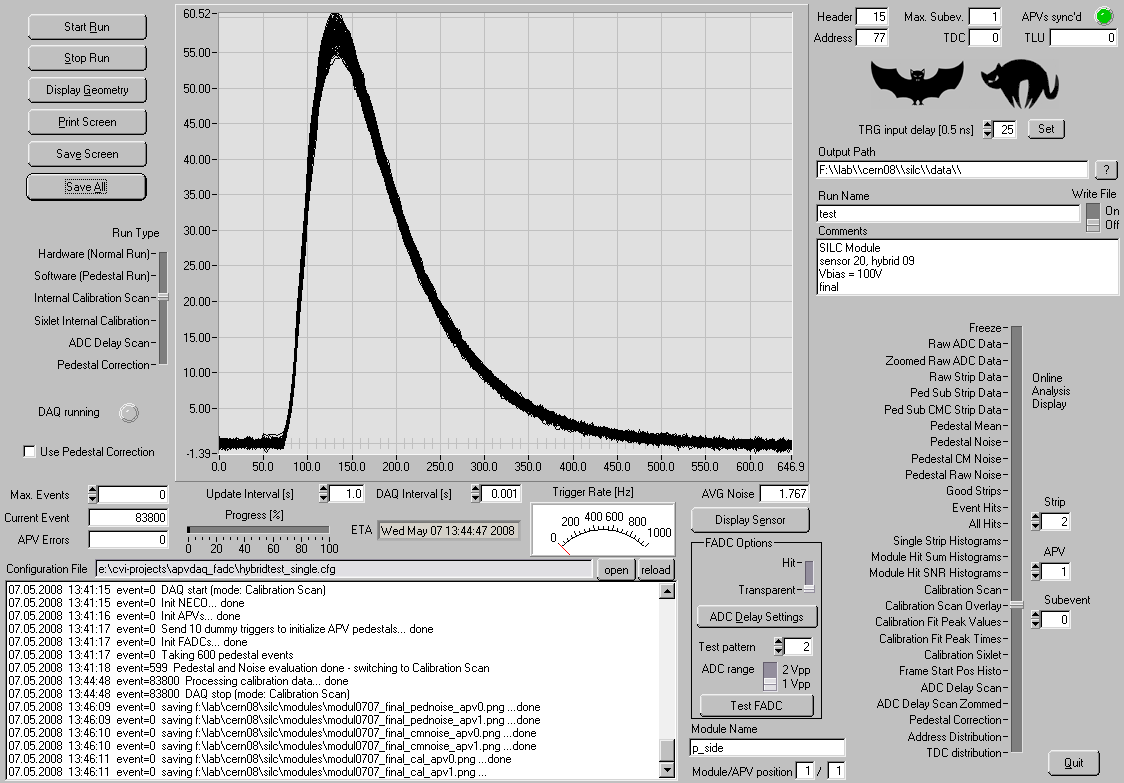

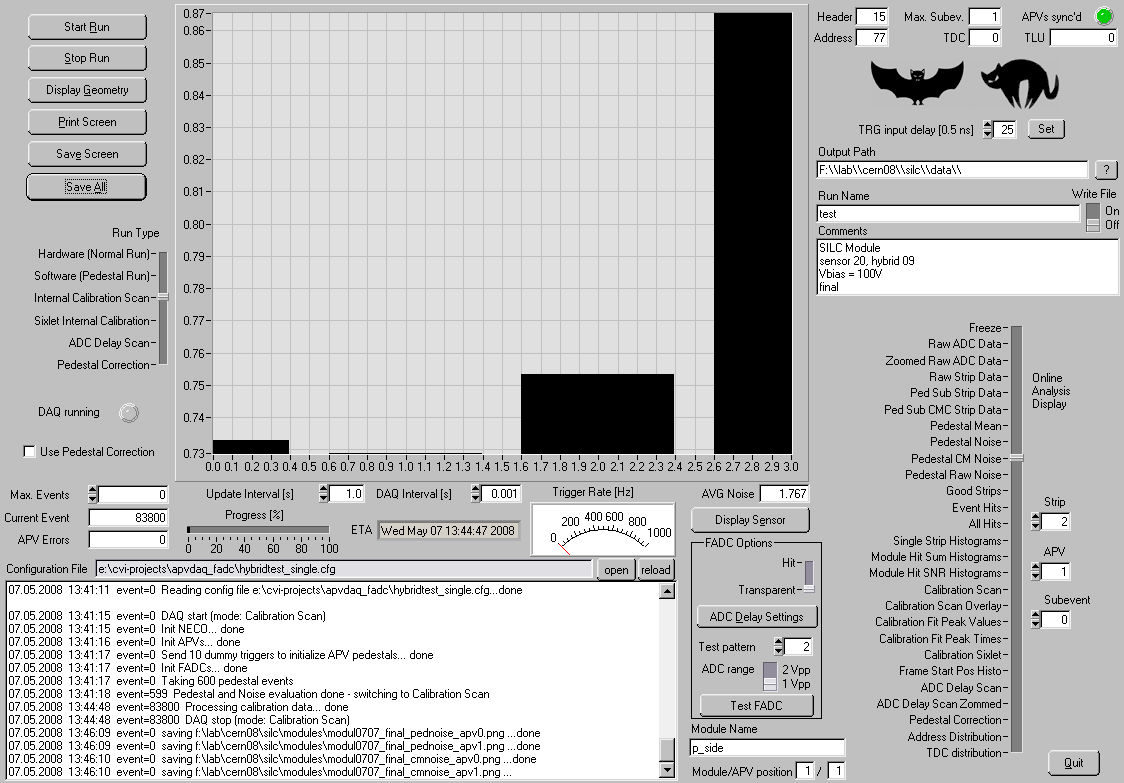

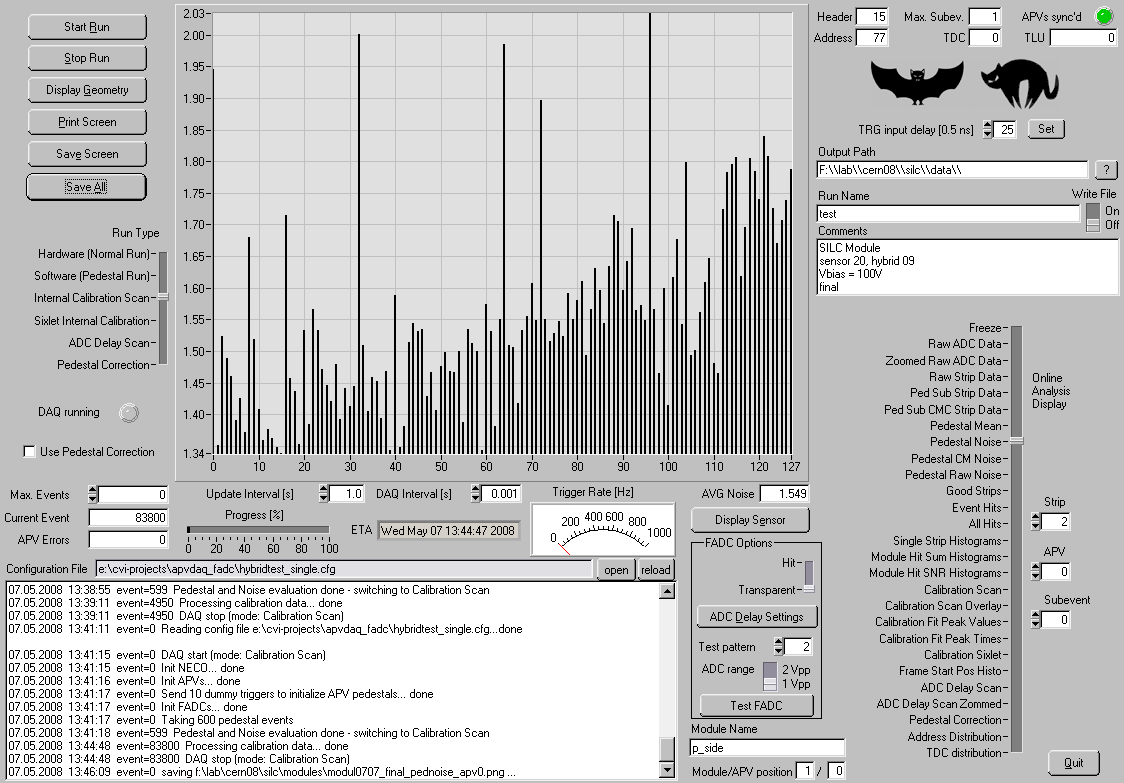

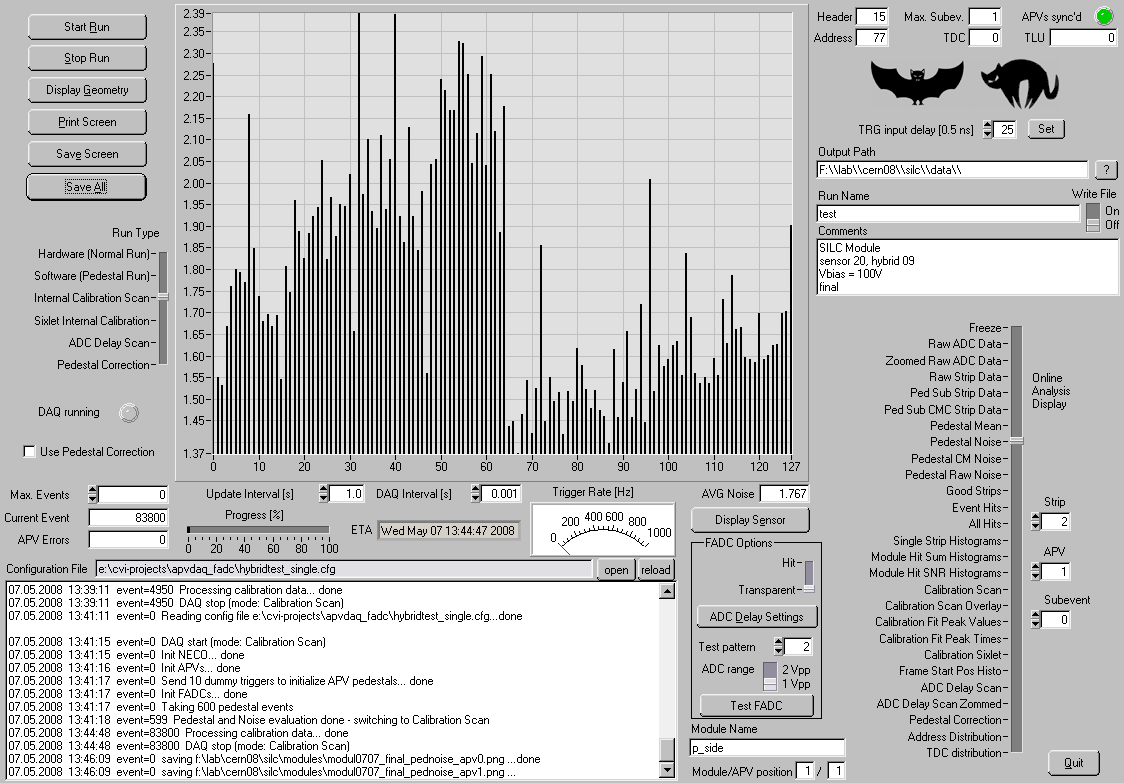

Christian Irmler | SPS Testbeam June08 | module | module 07/07 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100 V) = 20.2 nA

Ibias (200 V) = 21.9 nA |

| Attachment 1: modul0707_1row_cal_apv0.png

|

|

| Attachment 2: modul0707_1row_cal_apv1.png

|

|

| Attachment 3: modul0707_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul0707_1row_cmnoise_apv1.png

|

|

| Attachment 5: modul0707_1row_pednoise_apv0.png

|

|

| Attachment 6: modul0707_1row_pednoise_apv1.png

|

|

| Attachment 7: modul0707_final_cal_apv0.png

|

|

| Attachment 8: modul0707_final_cal_apv1.png

|

|

| Attachment 9: modul0707_final_cmnoise_apv0.png

|

|

| Attachment 10: modul0707_final_cmnoise_apv1.png

|

|

| Attachment 11: modul0707_final_pednoise_apv0.png

|

|

| Attachment 12: modul0707_final_pednoise_apv1.png

|

|

|

|

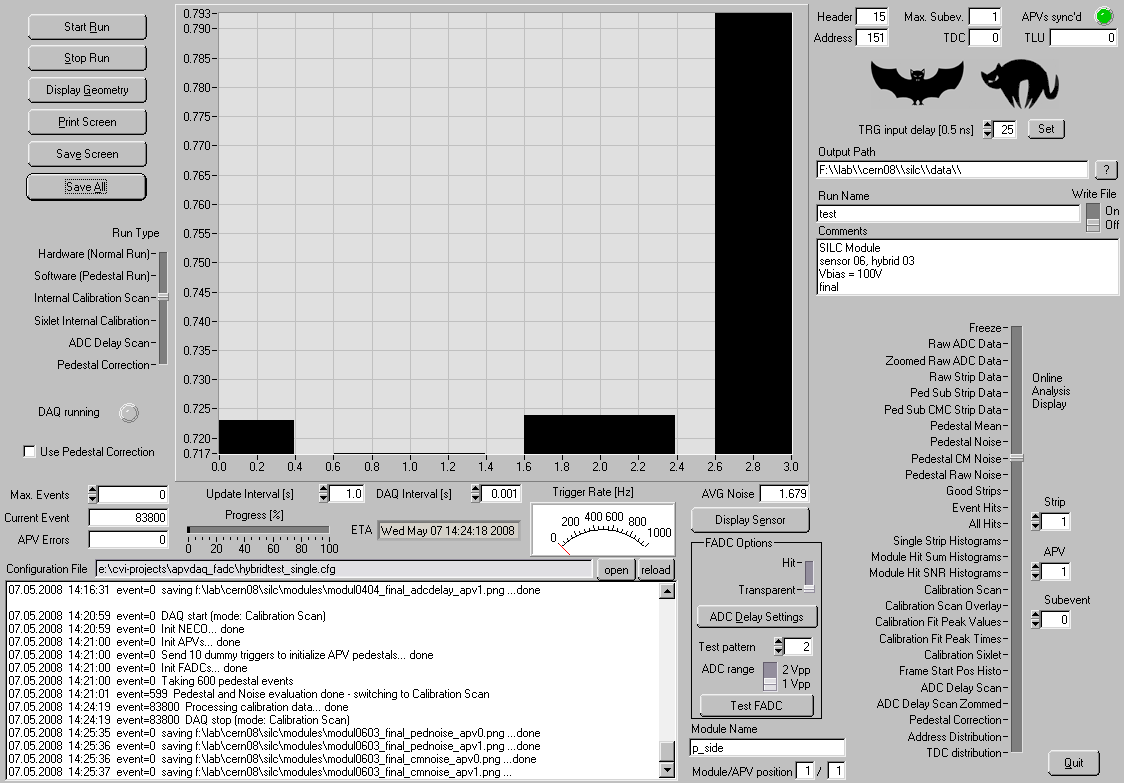

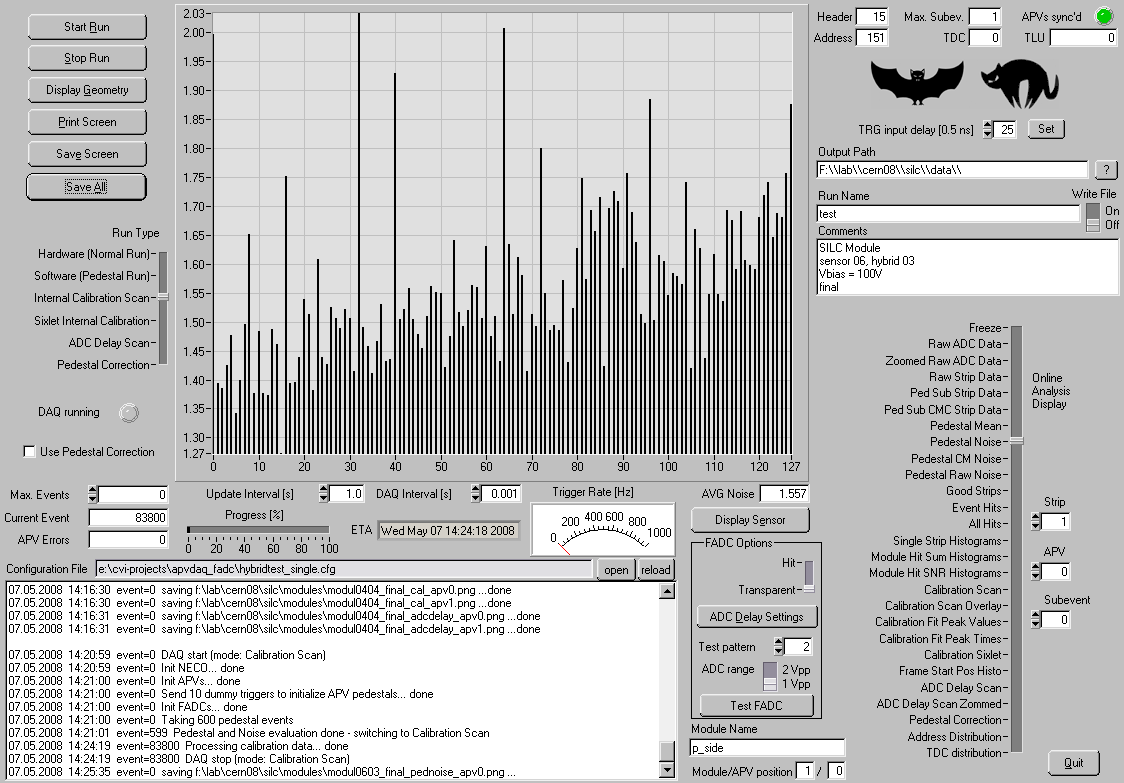

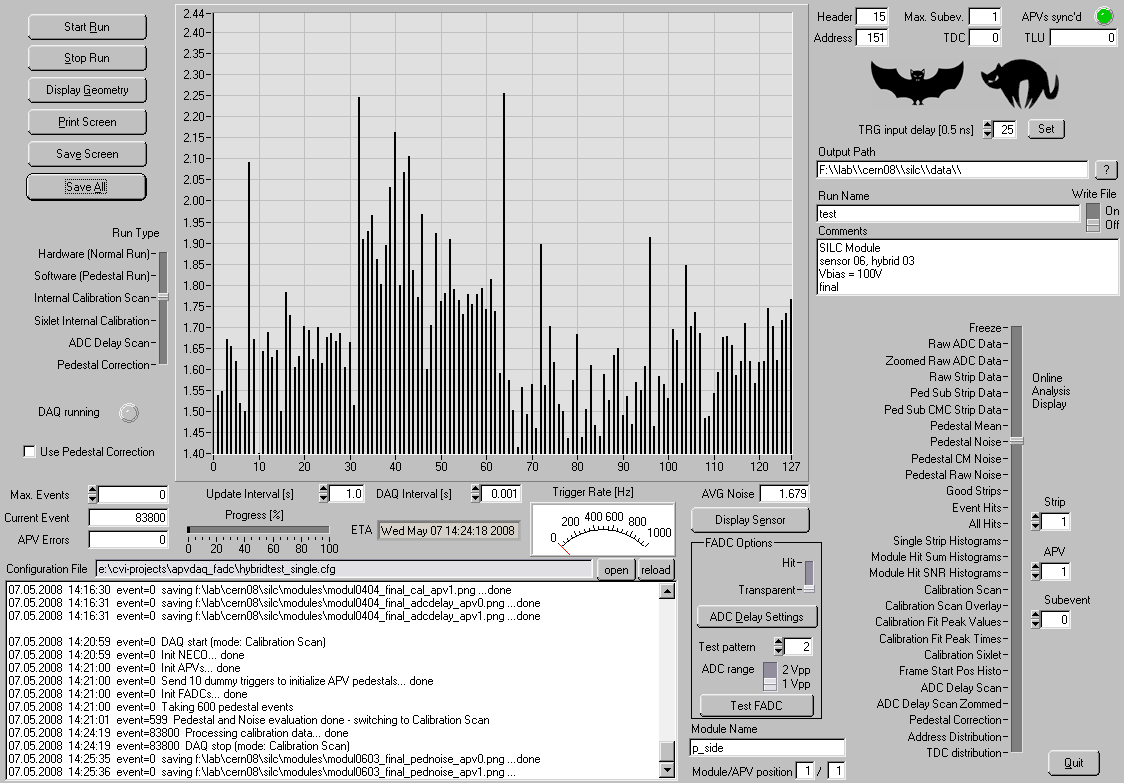

11

|

Fri May 9 09:56:15 2008 |

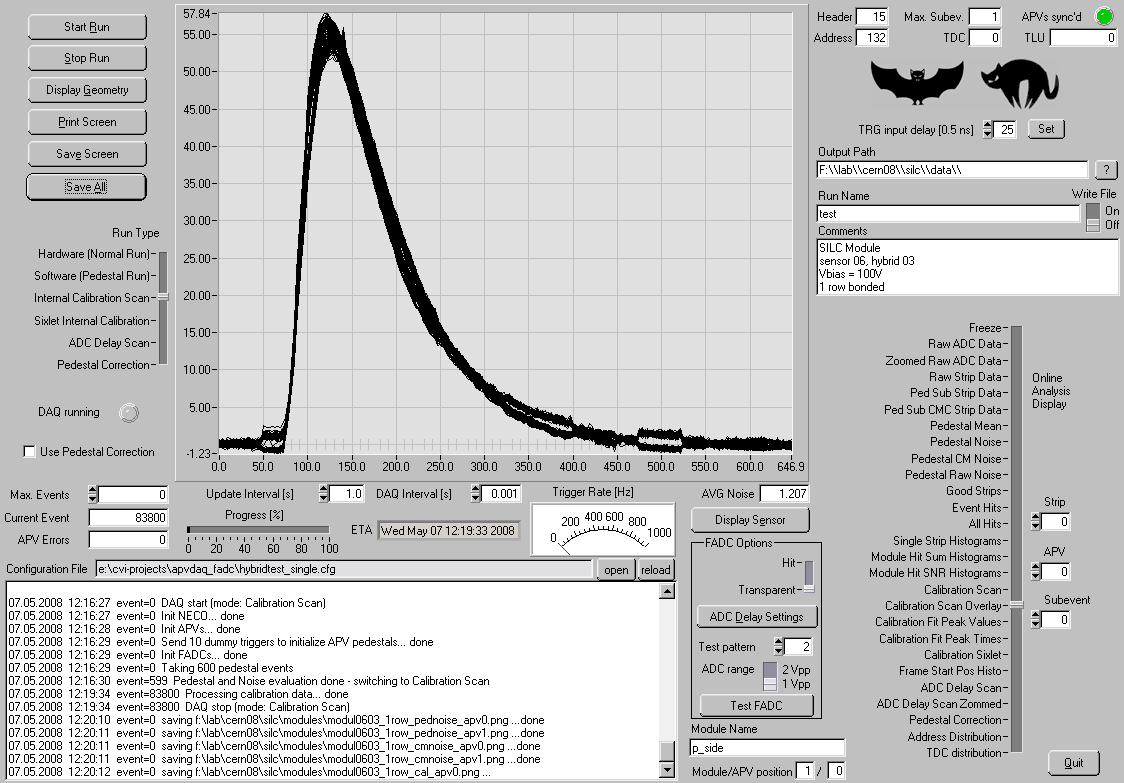

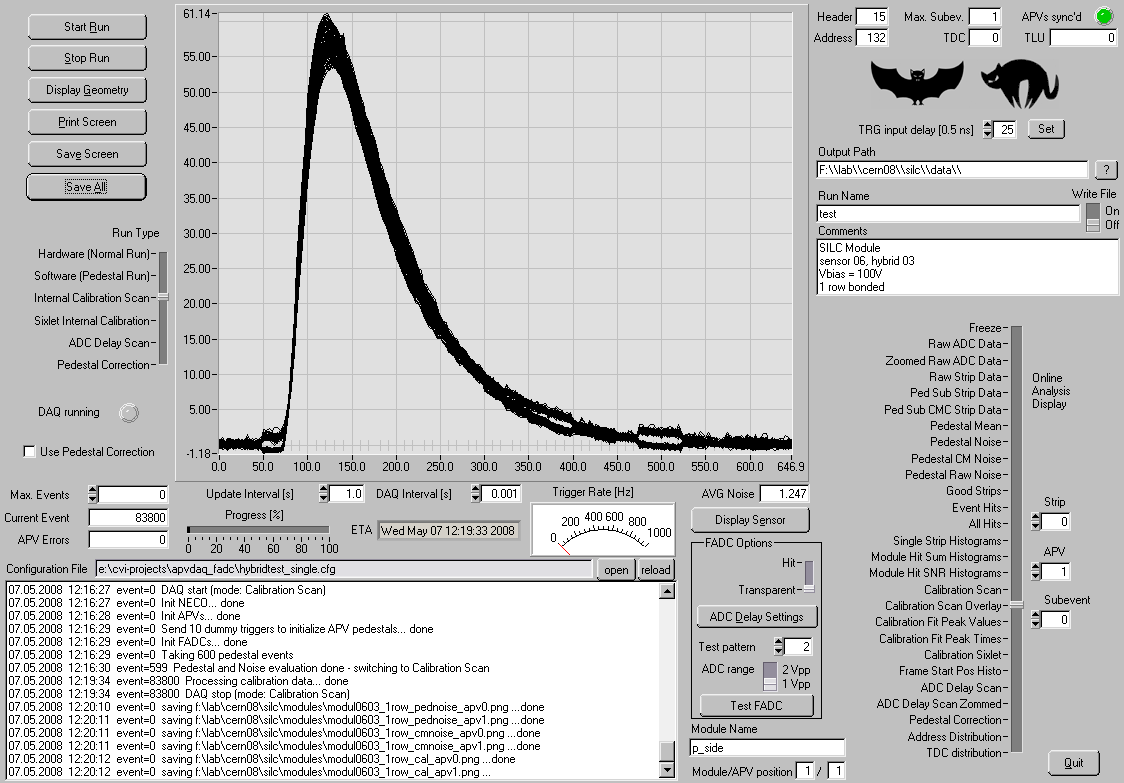

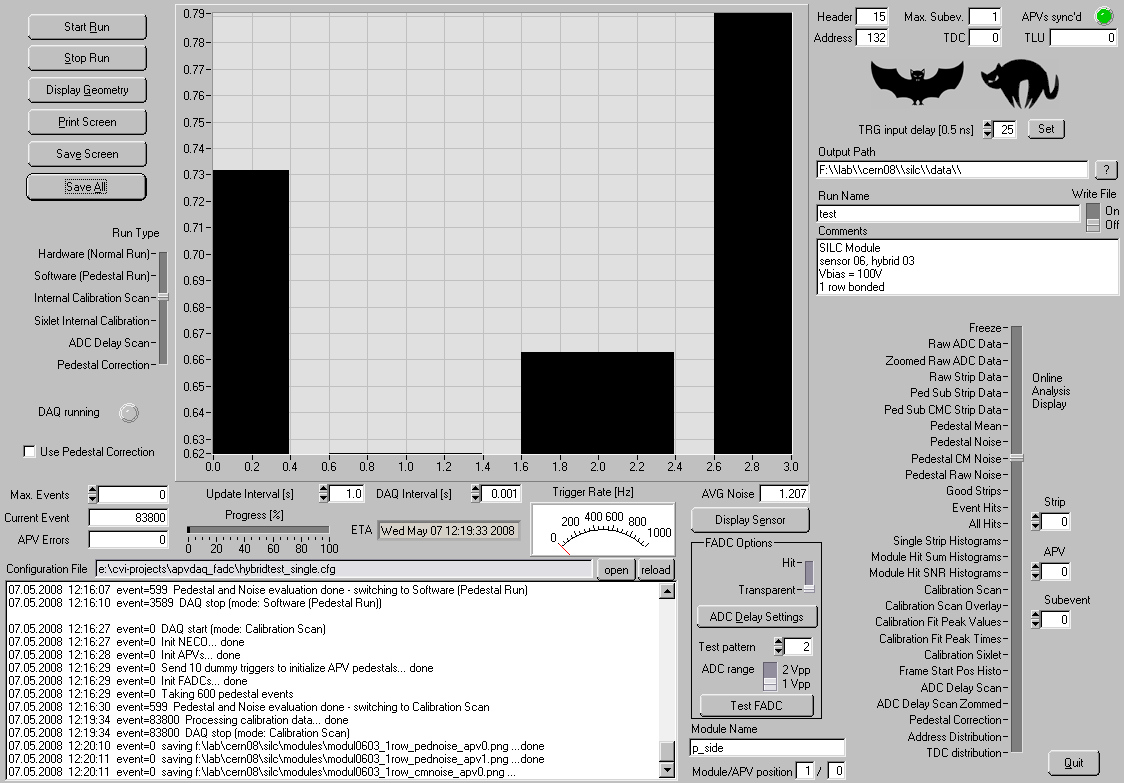

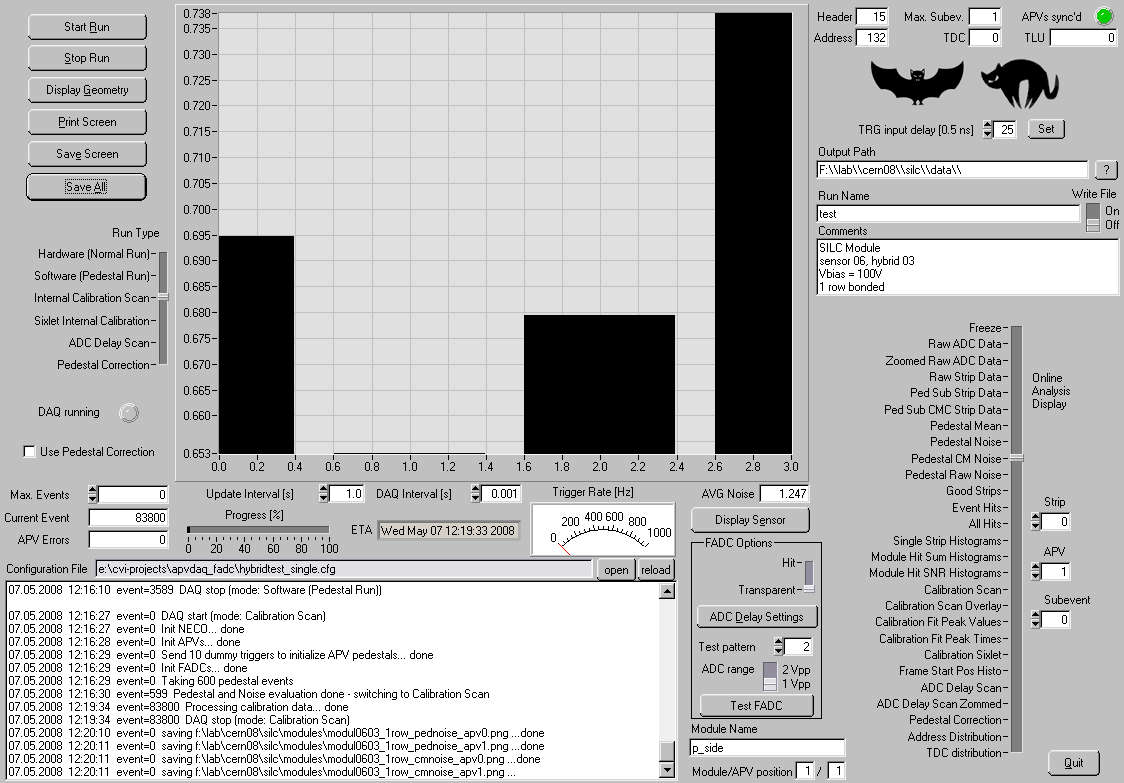

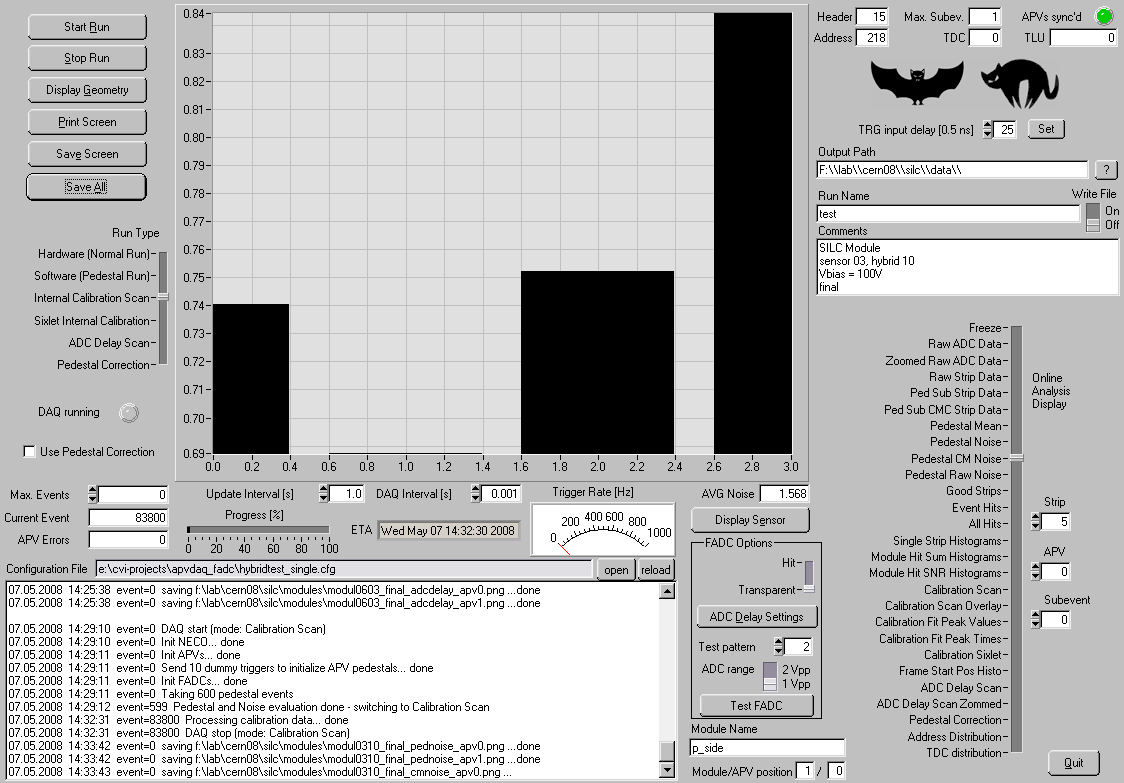

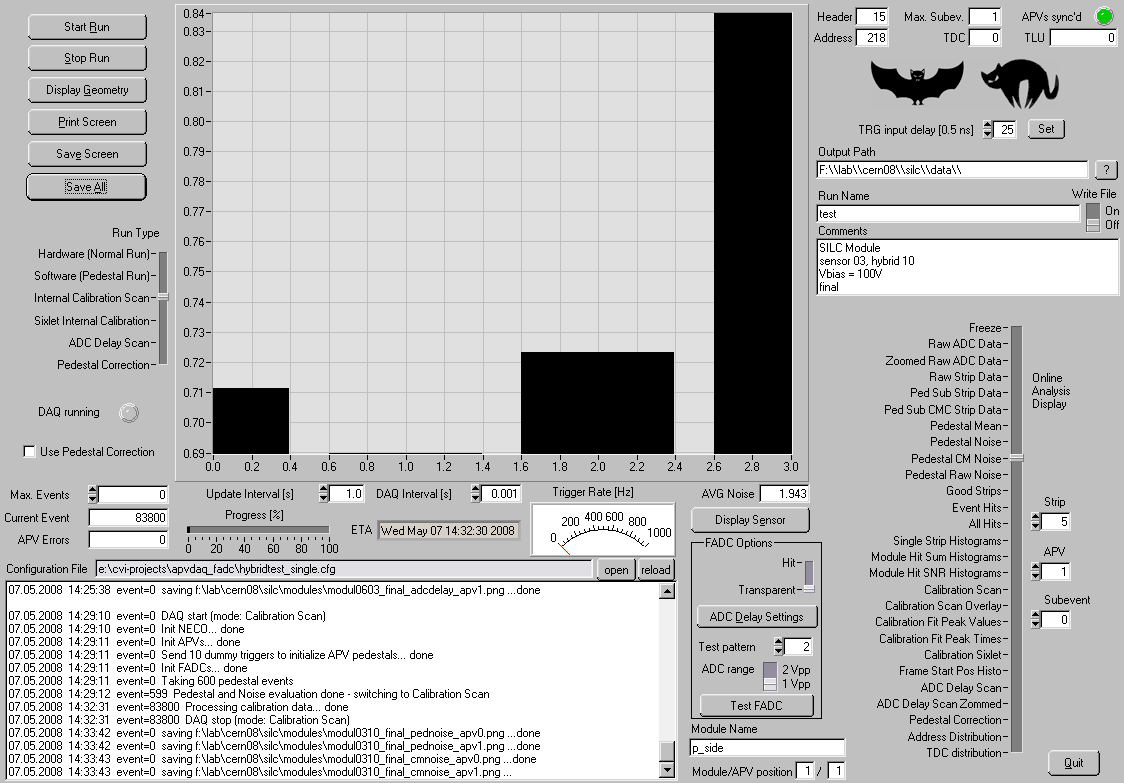

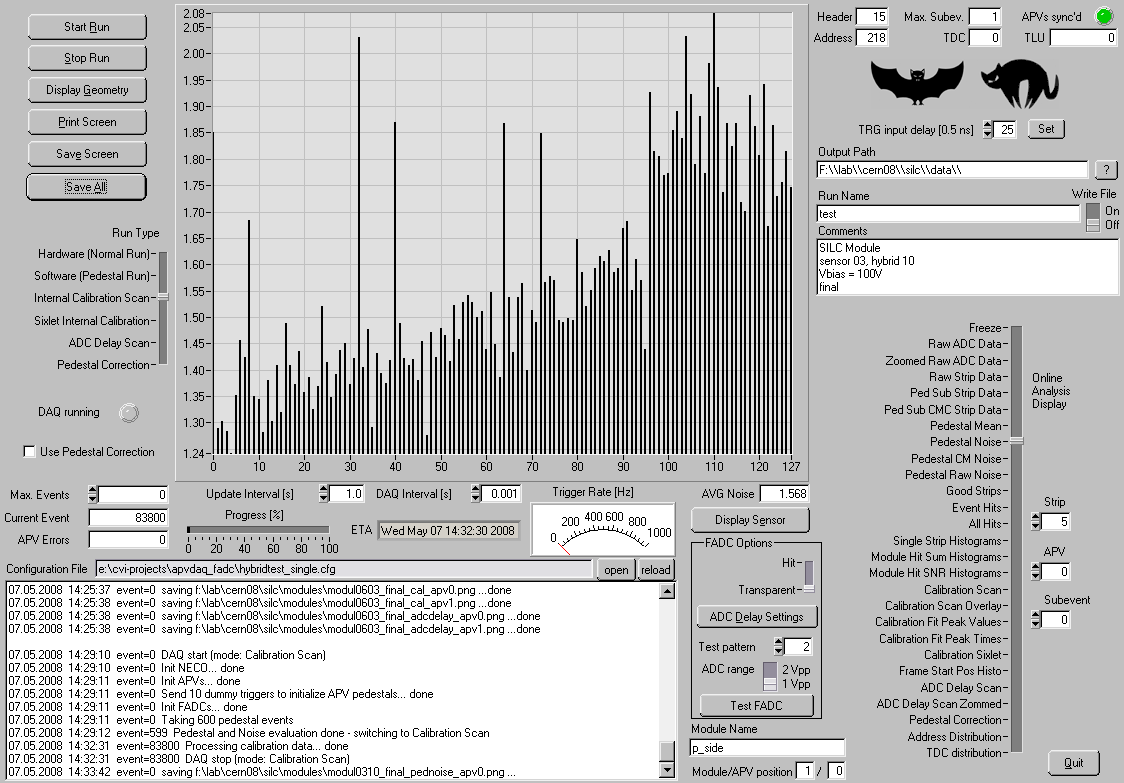

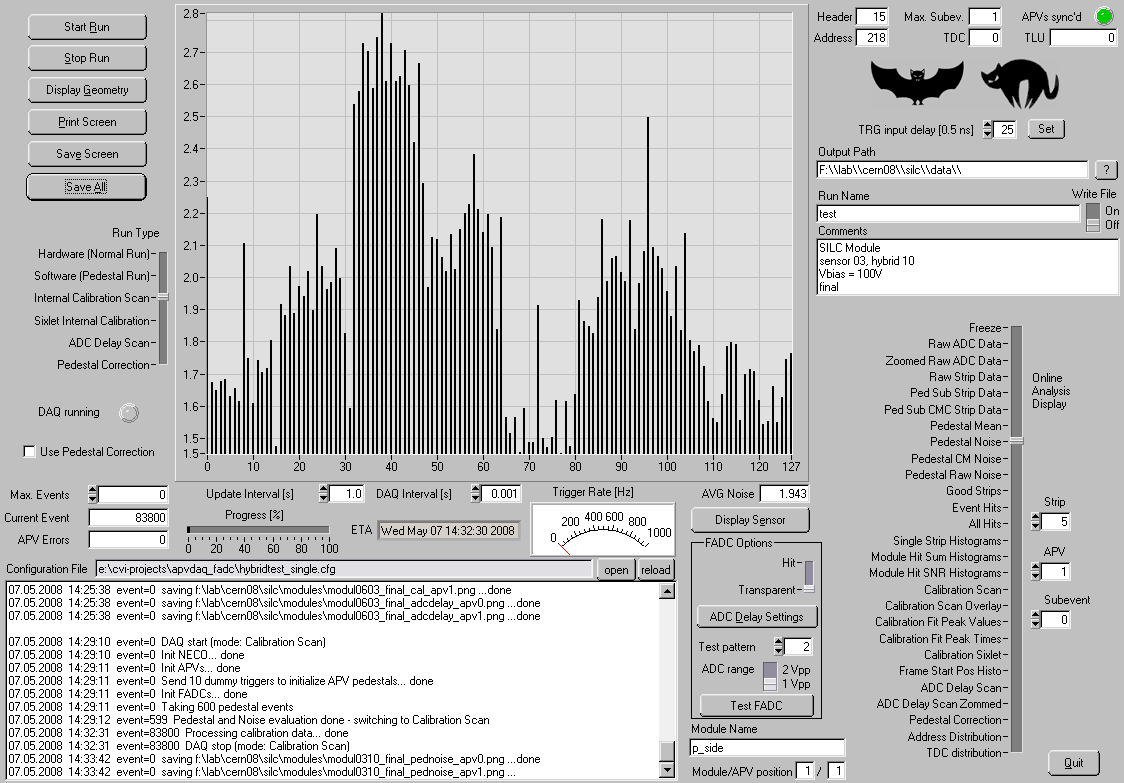

Christian Irmler | SPS Testbeam June08 | module | module 06/03 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100 V) = 26.5 nA

Ibias (200 V) = 37.8 nA |

| Attachment 1: modul0603_1row_cal_apv0.png

|

|

| Attachment 2: modul0603_1row_cal_apv1.png

|

|

| Attachment 3: modul0603_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul0603_1row_cmnoise_apv1.png

|

|

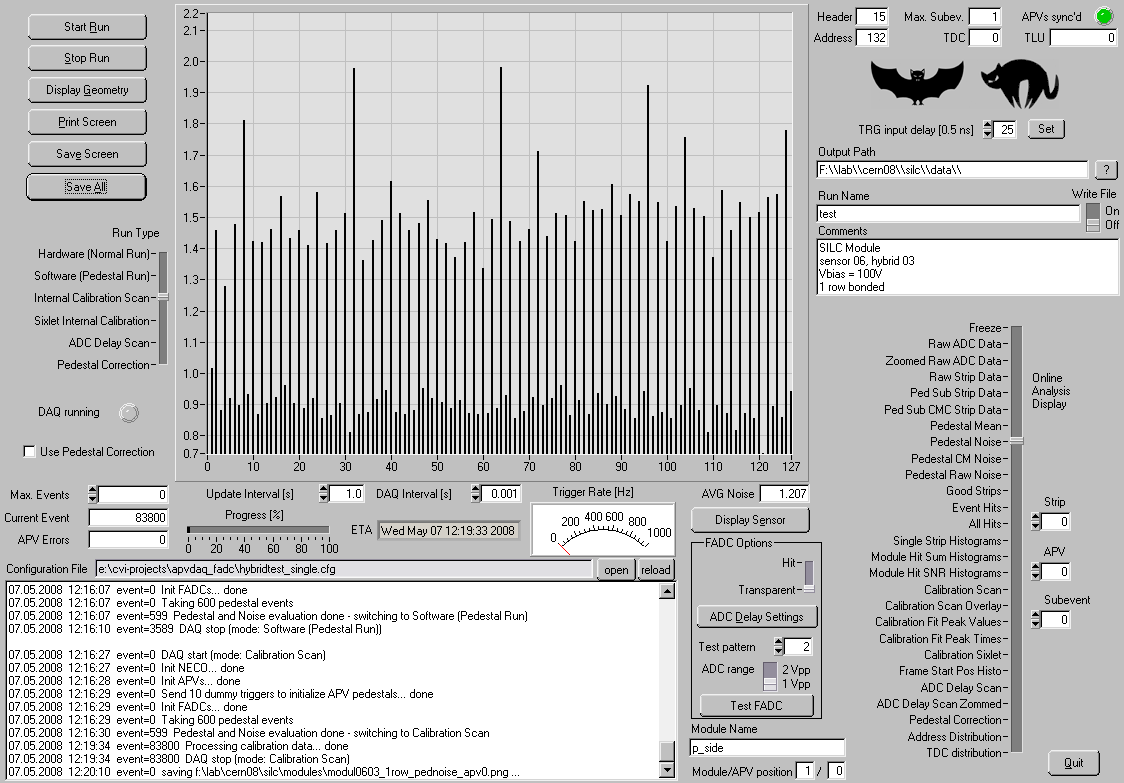

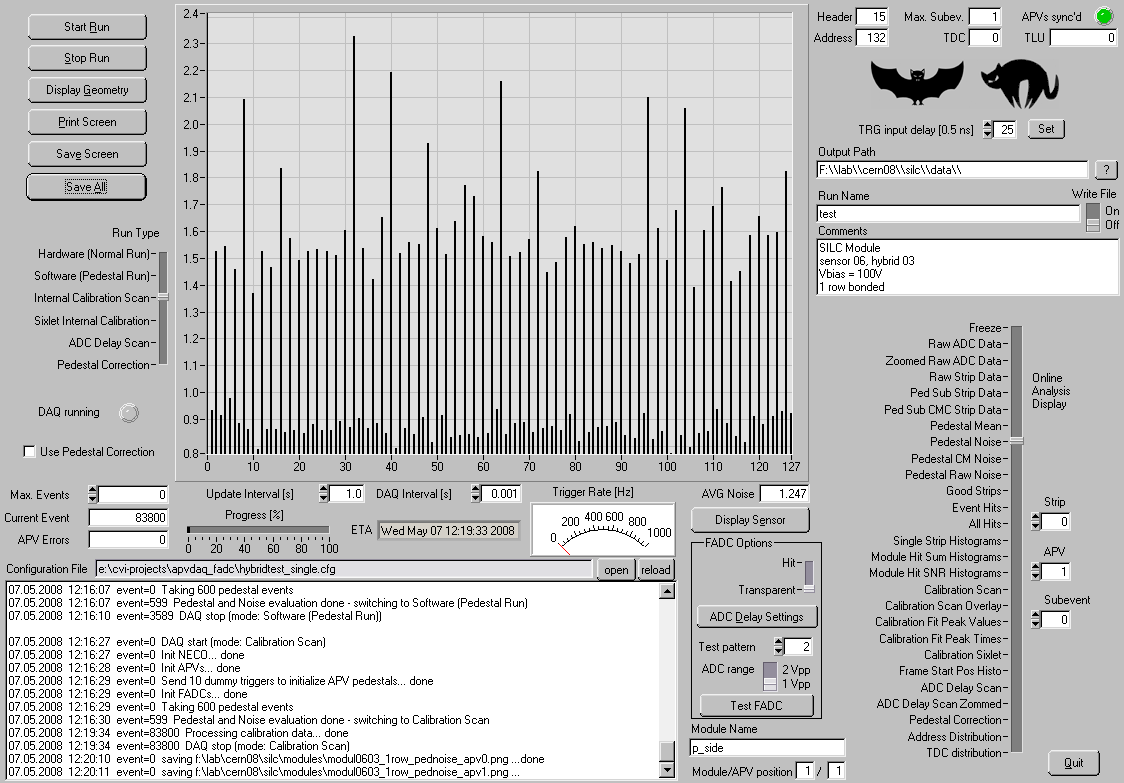

| Attachment 5: modul0603_1row_pednoise_apv0.png

|

|

| Attachment 6: modul0603_1row_pednoise_apv1.png

|

|

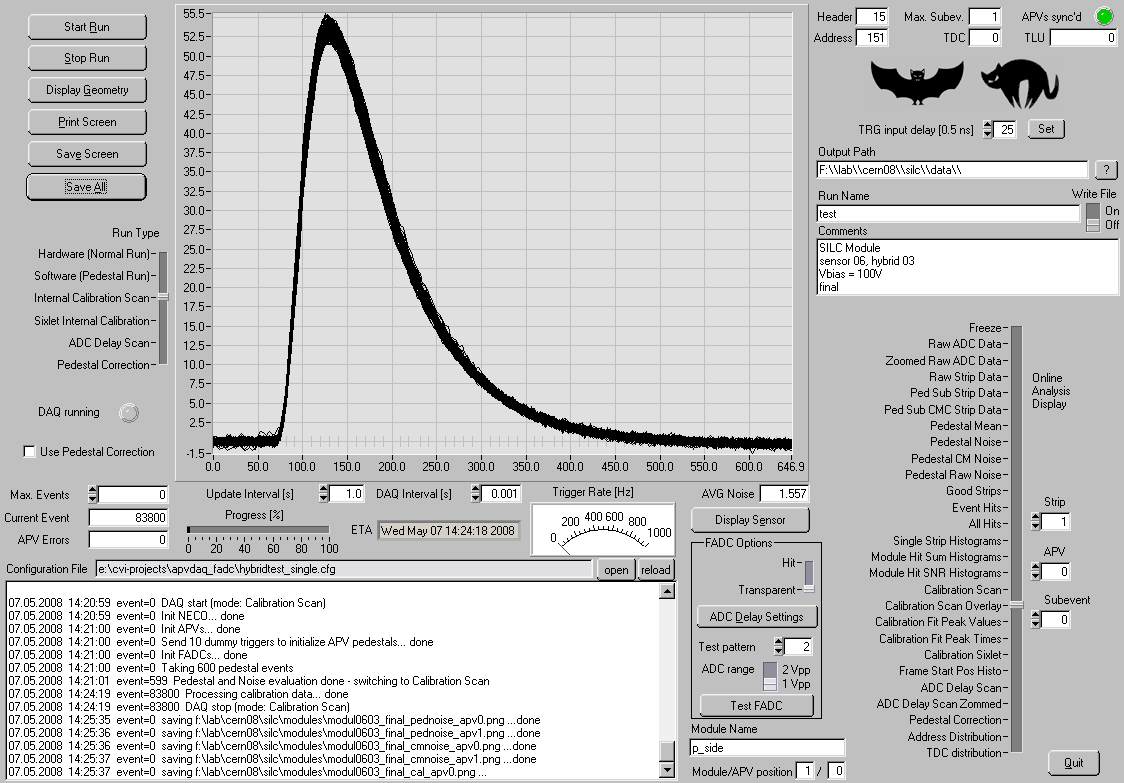

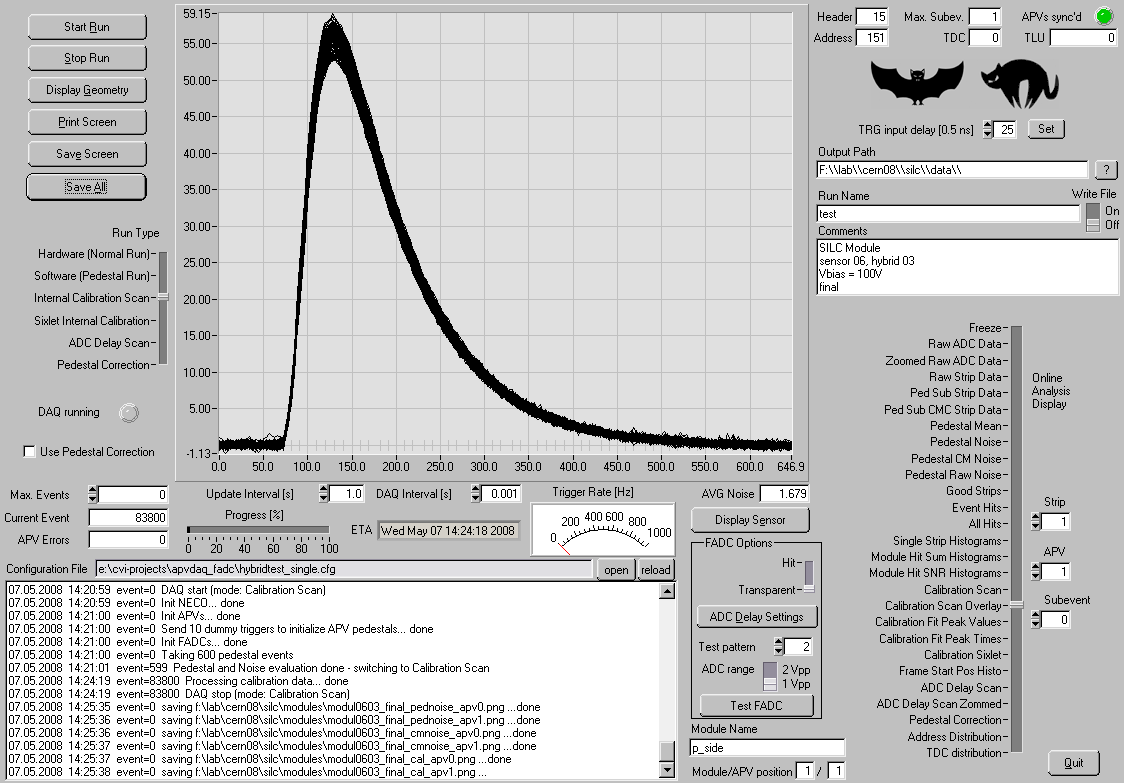

| Attachment 7: modul0603_final_cal_apv0.png

|

|

| Attachment 8: modul0603_final_cal_apv1.png

|

|

| Attachment 9: modul0603_final_cmnoise_apv0.png

|

|

| Attachment 10: modul0603_final_cmnoise_apv1.png

|

|

| Attachment 11: modul0603_final_pednoise_apv0.png

|

|

| Attachment 12: modul0603_final_pednoise_apv1.png

|

|

|

|

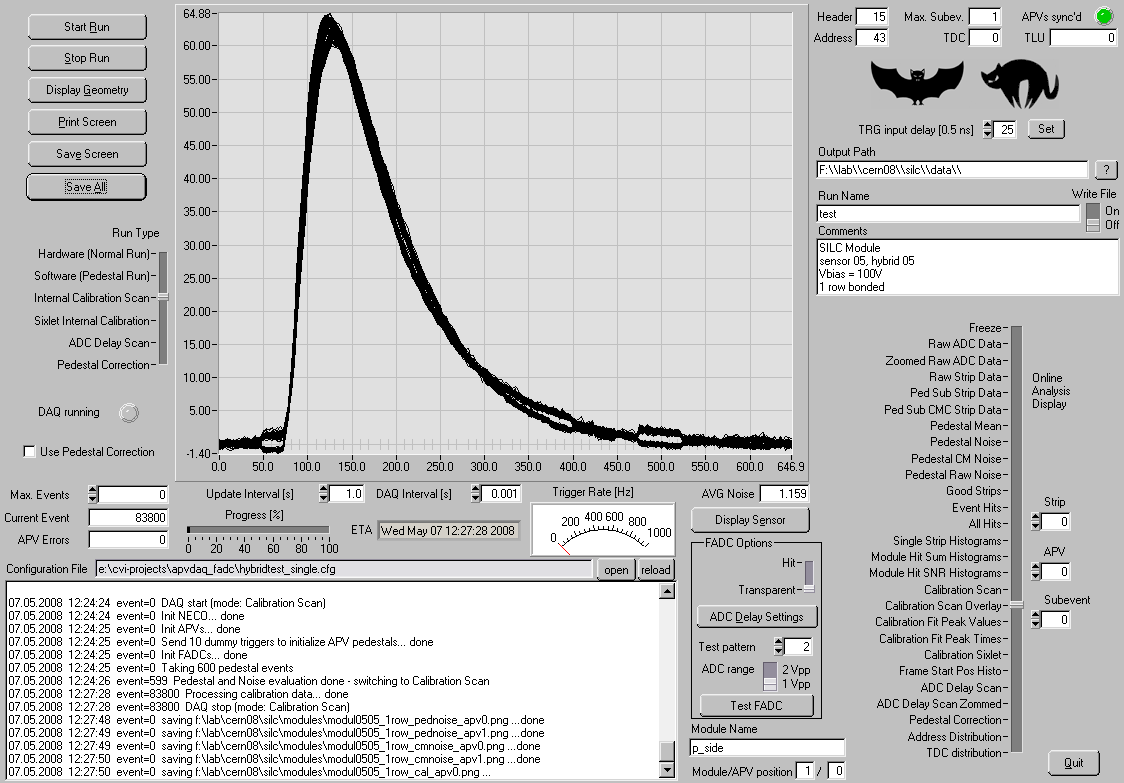

13

|

Fri May 9 10:04:26 2008 |

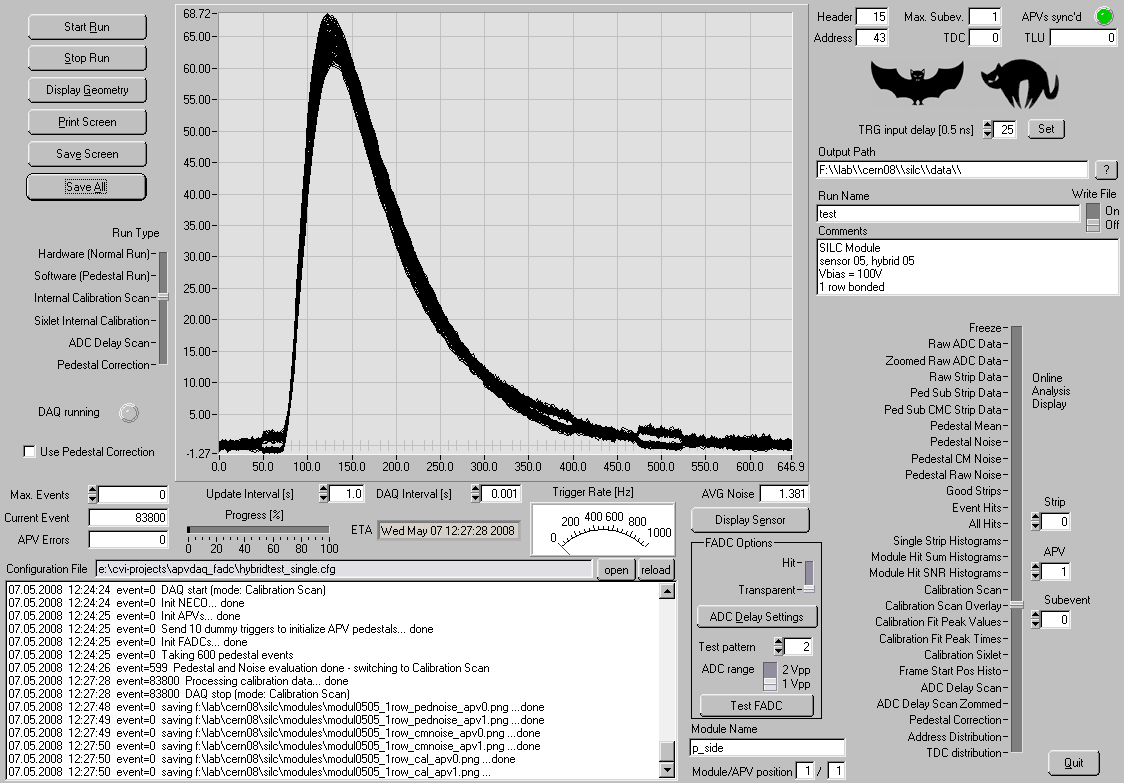

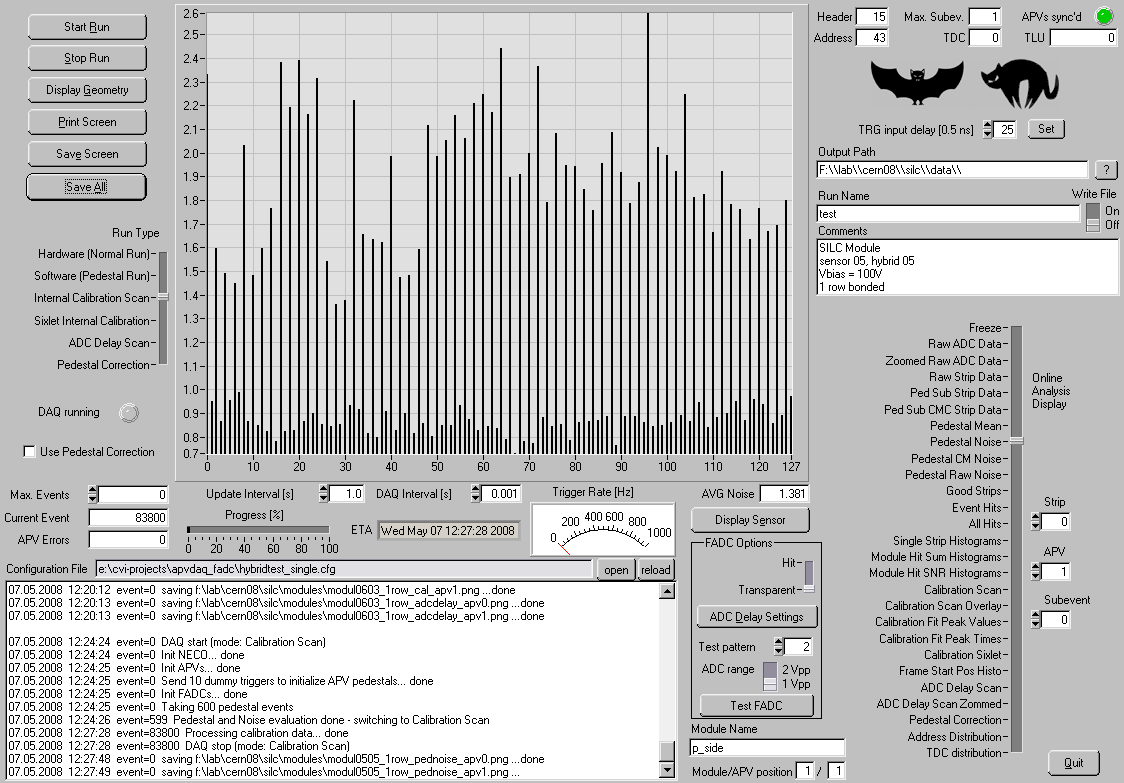

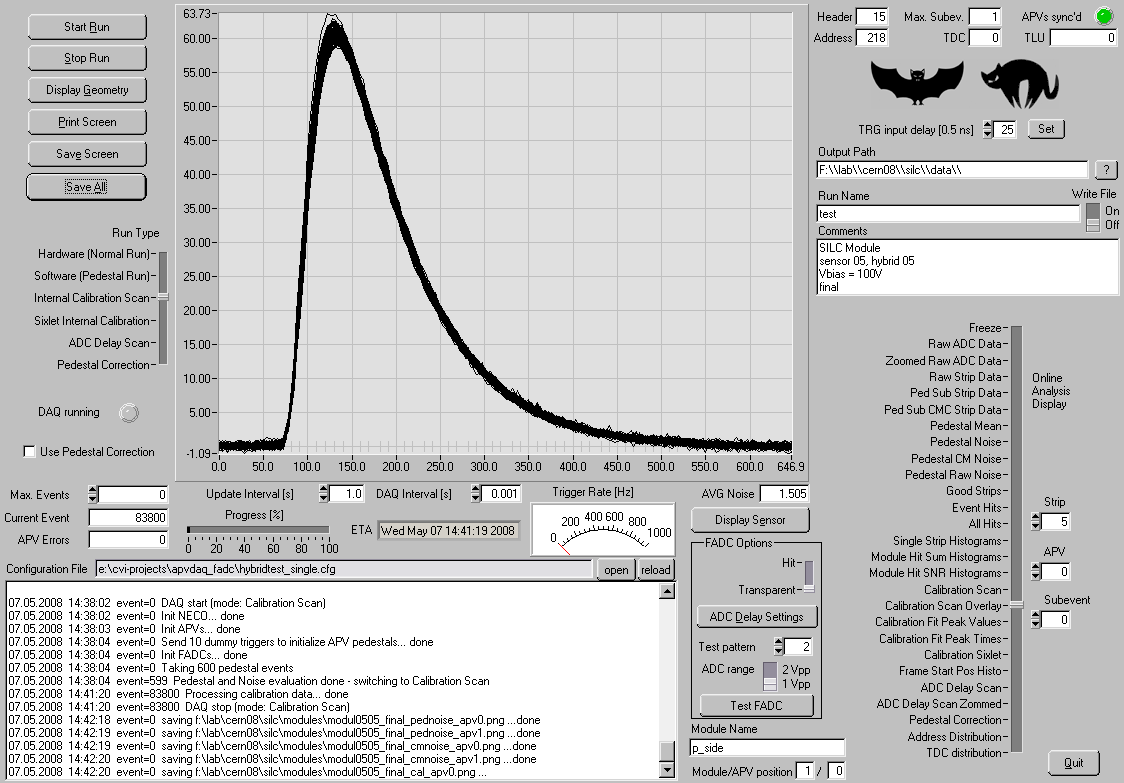

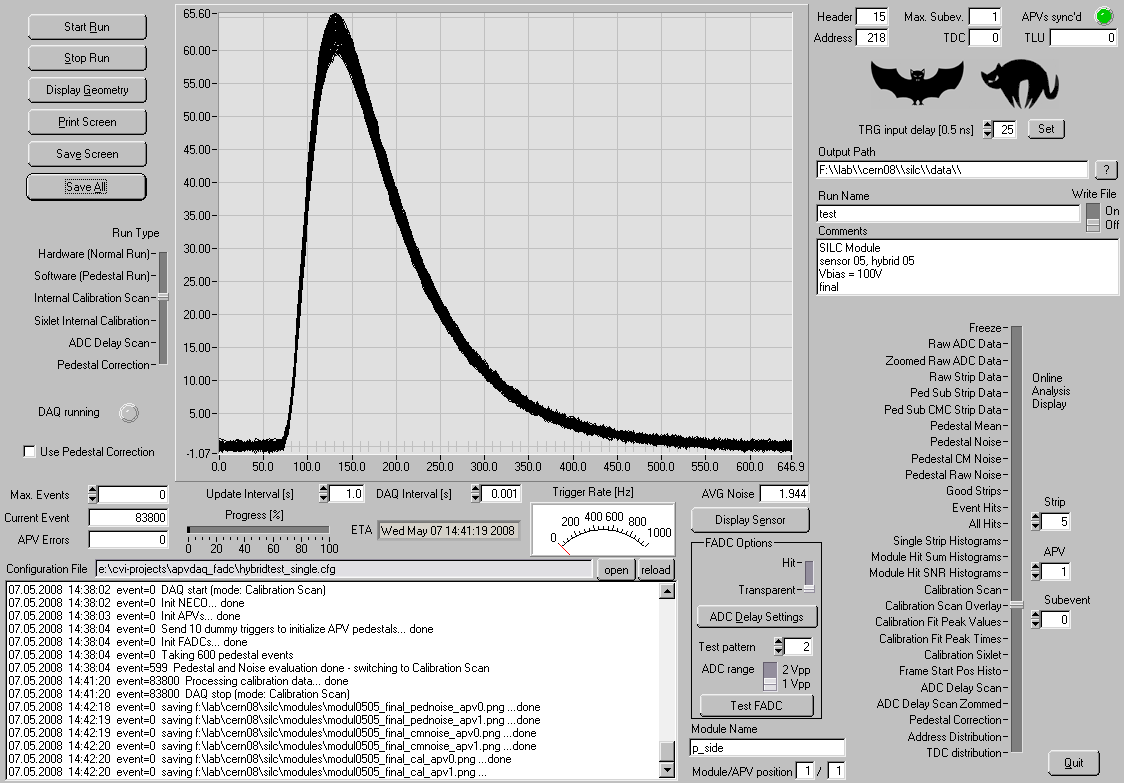

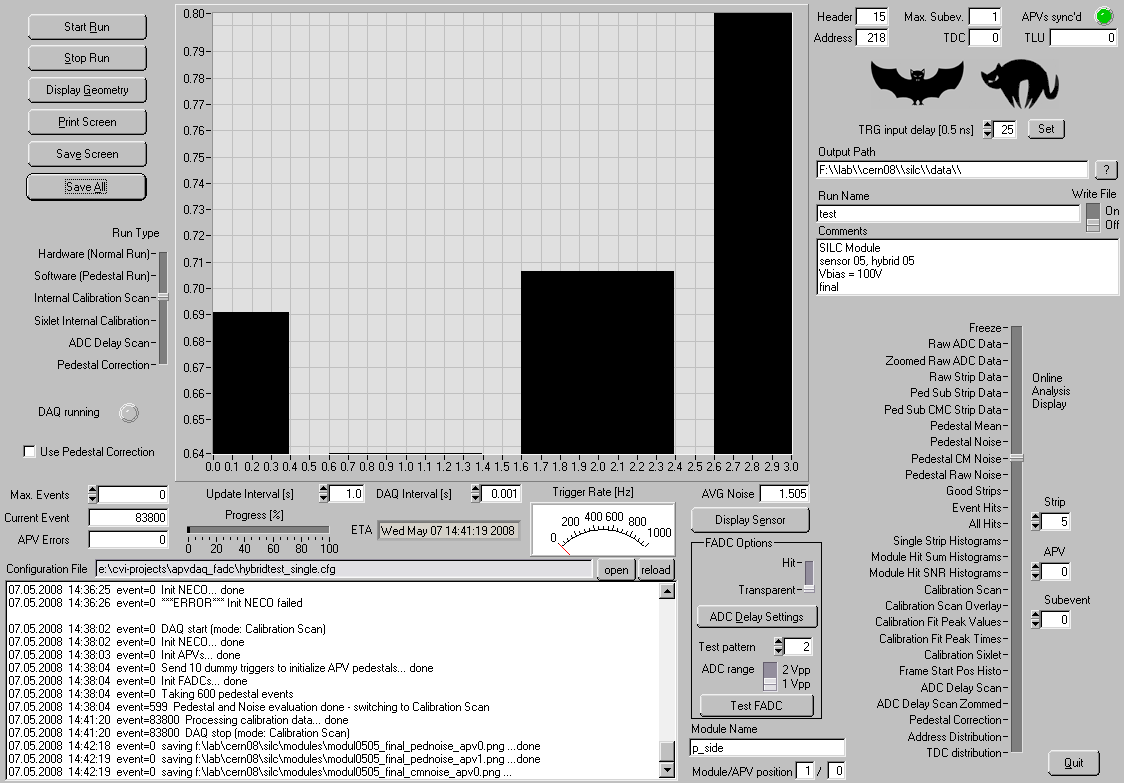

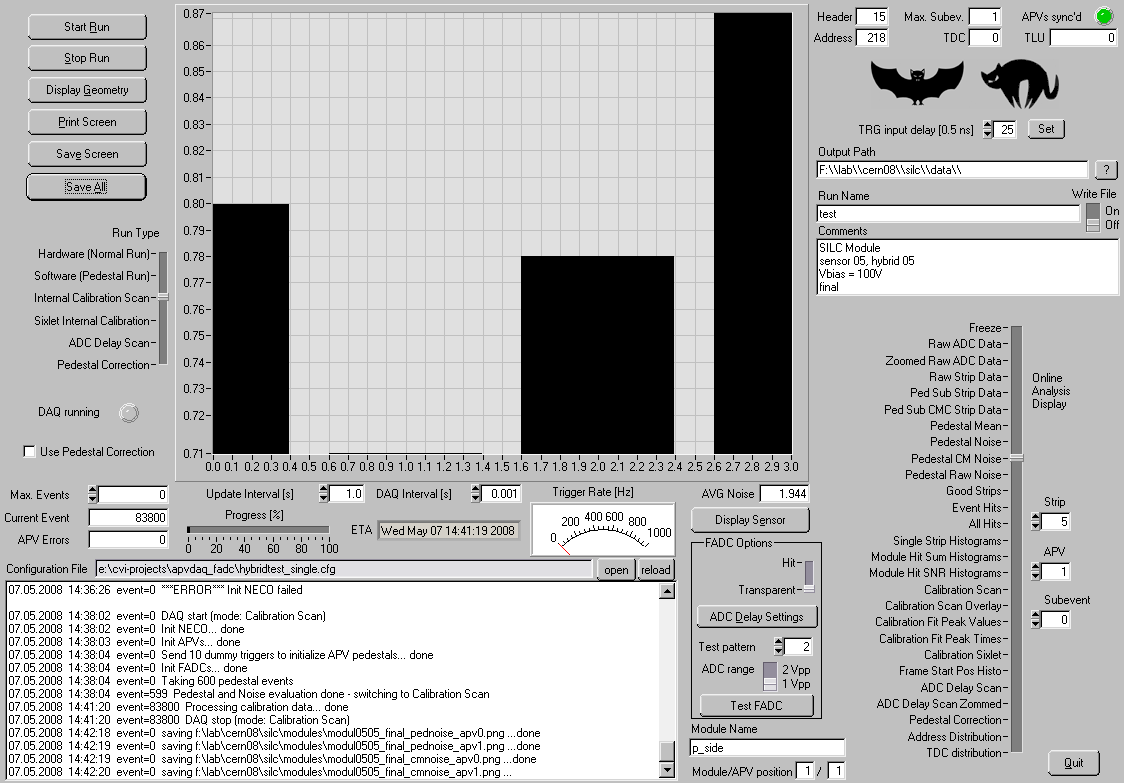

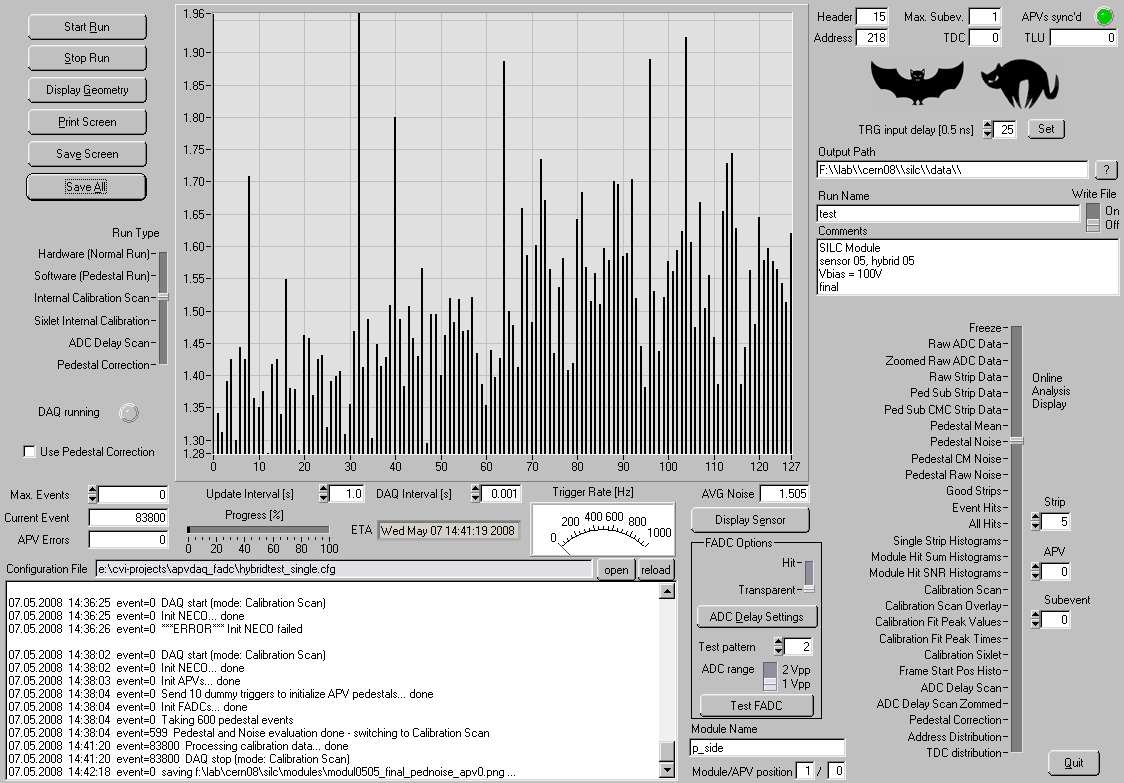

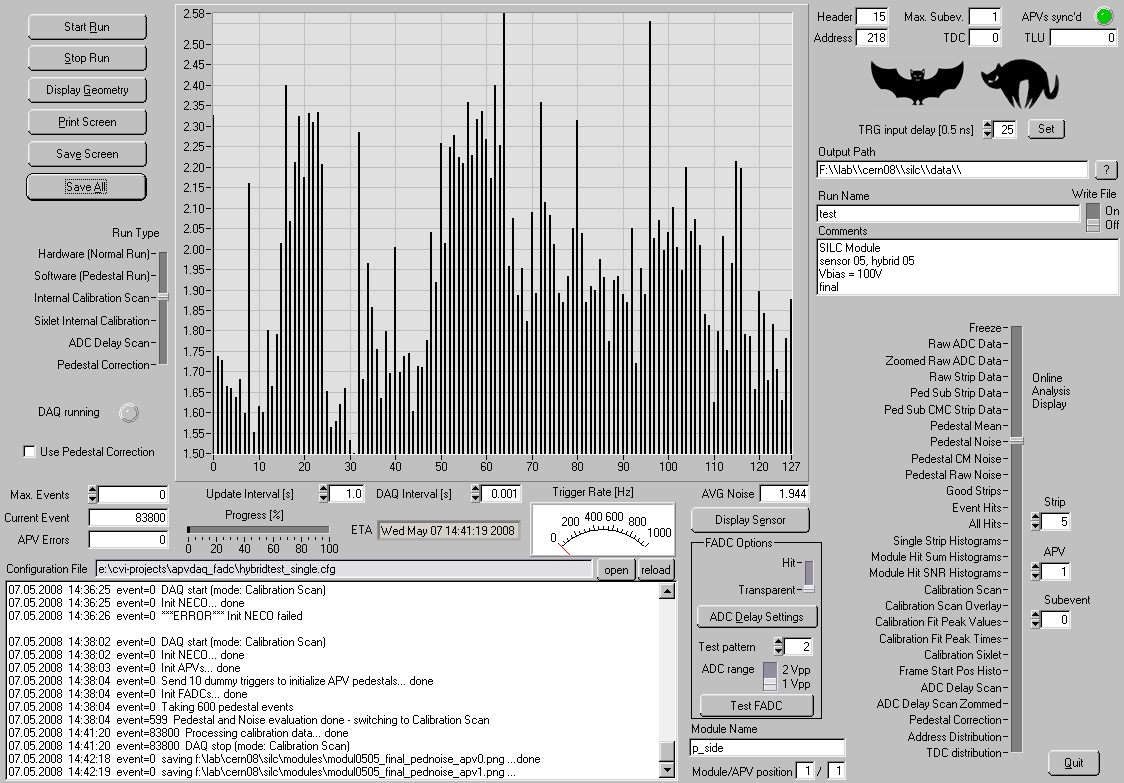

Christian Irmler | SPS Testbeam June08 | module | module 05/05 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100 V) = 18.0 nA

Ibias (200 V) = 23.6 nA |

| Attachment 1: modul0505_1row_cal_apv0.png

|

|

| Attachment 2: modul0505_1row_cal_apv1.png

|

|

| Attachment 3: modul0505_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul0505_1row_cmnoise_apv1.png

|

|

| Attachment 5: modul0505_1row_pednoise_apv0.png

|

|

| Attachment 6: modul0505_1row_pednoise_apv1.png

|

|

| Attachment 7: modul0505_final_cal_apv0.png

|

|

| Attachment 8: modul0505_final_cal_apv1.png

|

|

| Attachment 9: modul0505_final_cmnoise_apv0.png

|

|

| Attachment 10: modul0505_final_cmnoise_apv1.png

|

|

| Attachment 11: modul0505_final_pednoise_apv0.png

|

|

| Attachment 12: modul0505_final_pednoise_apv1.png

|

|

|

|

10

|

Wed May 7 19:05:08 2008 |

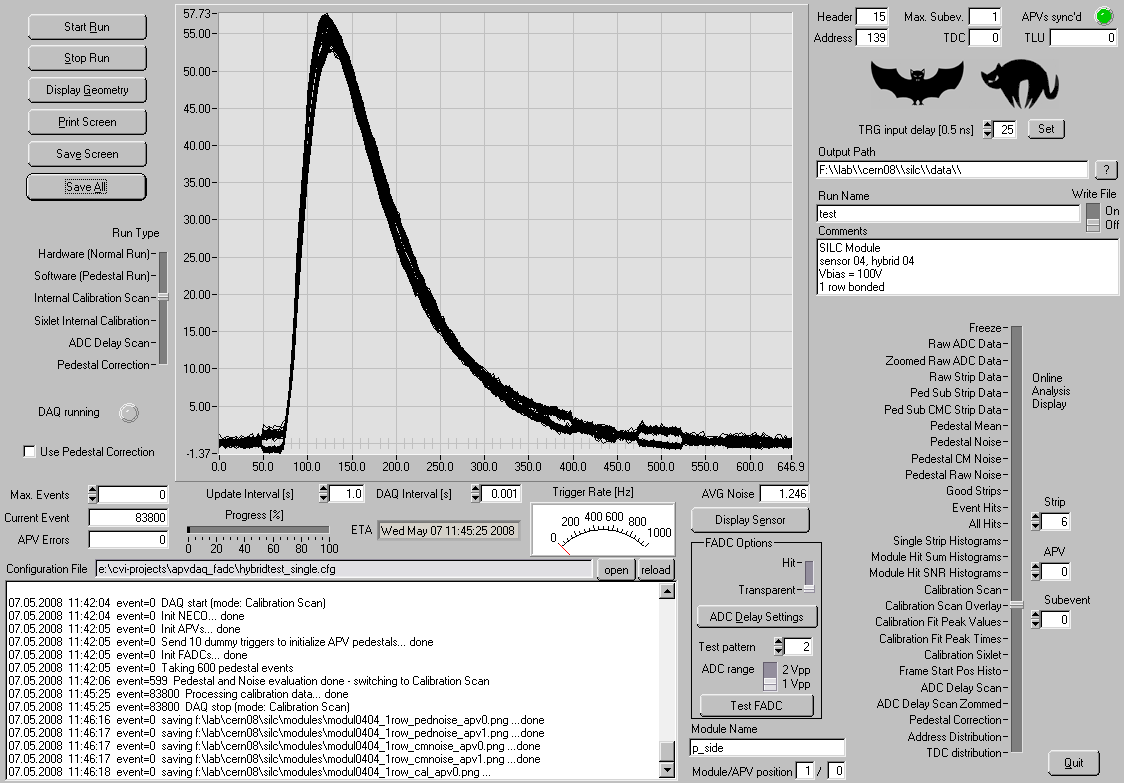

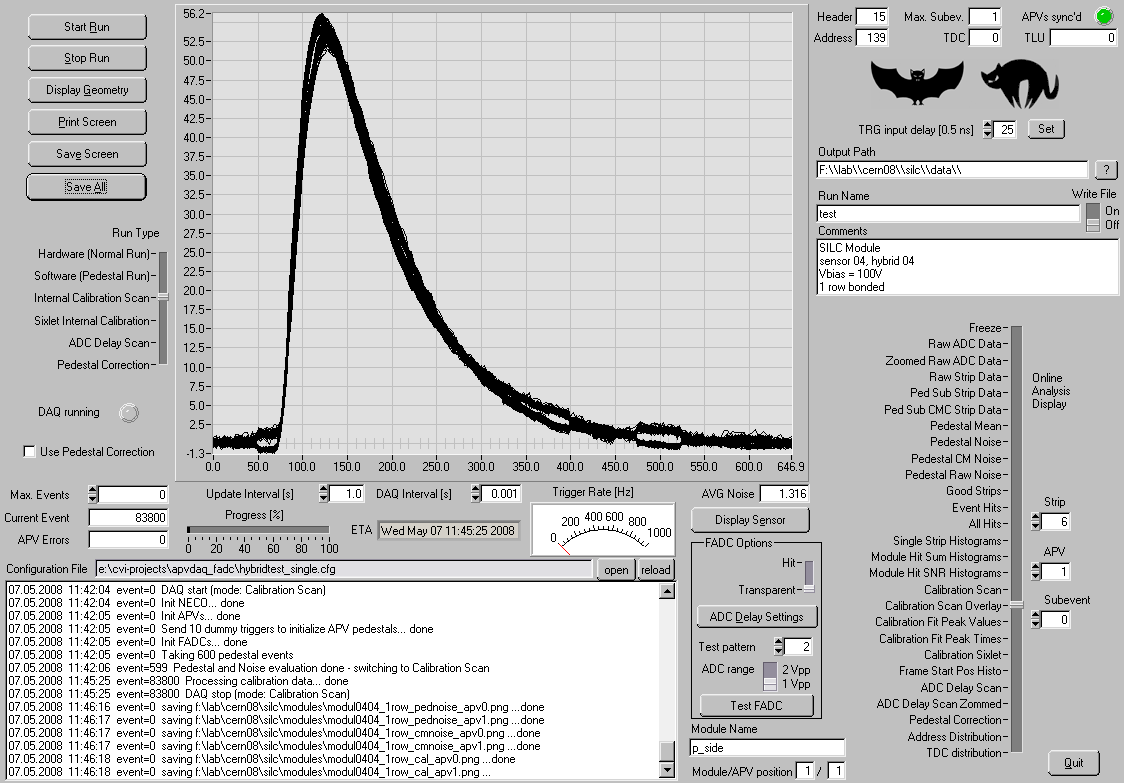

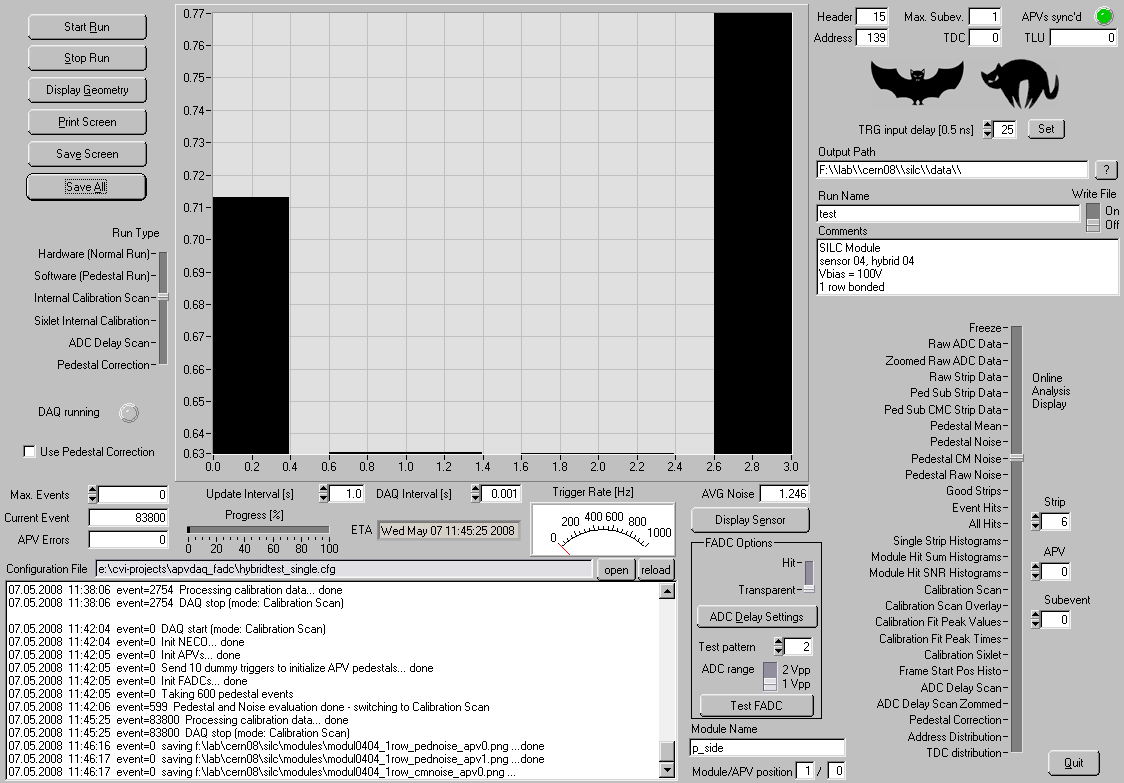

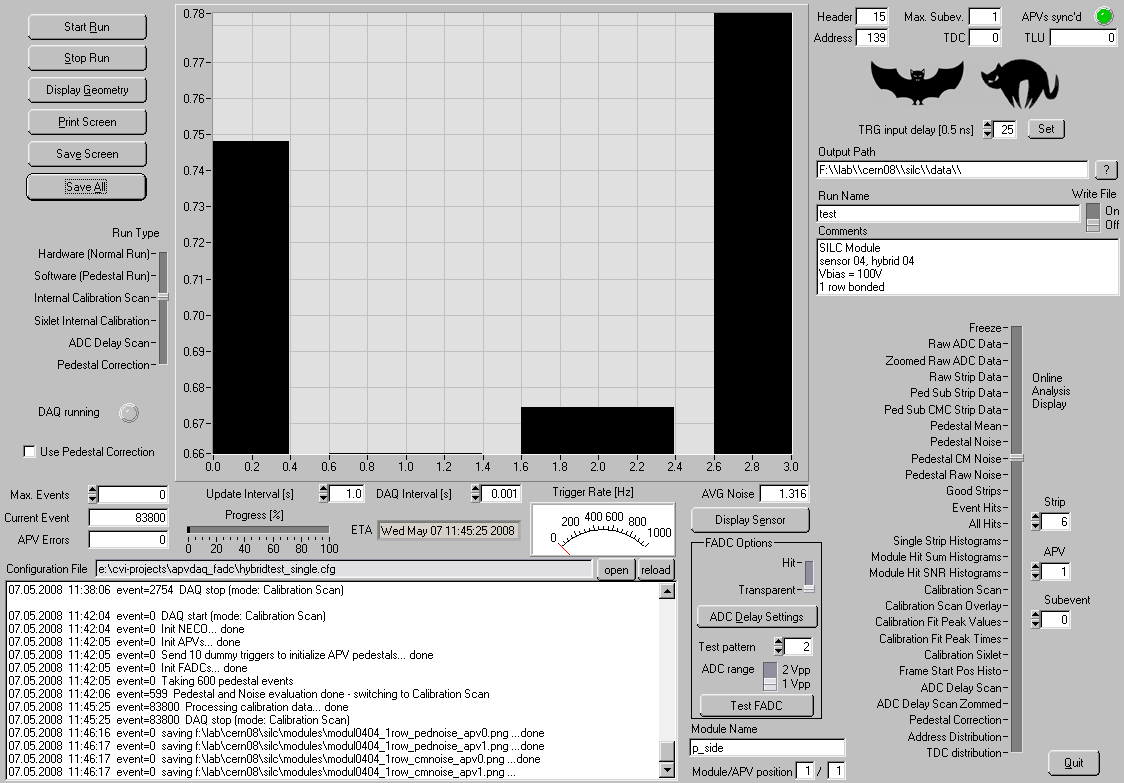

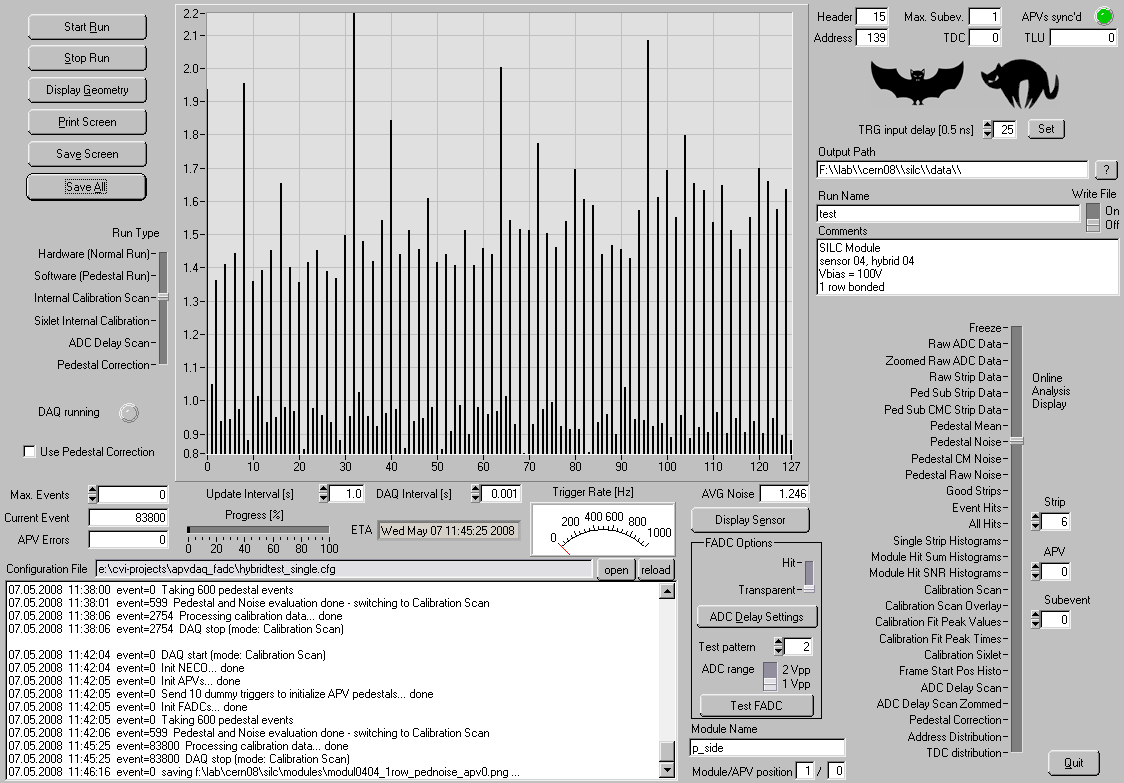

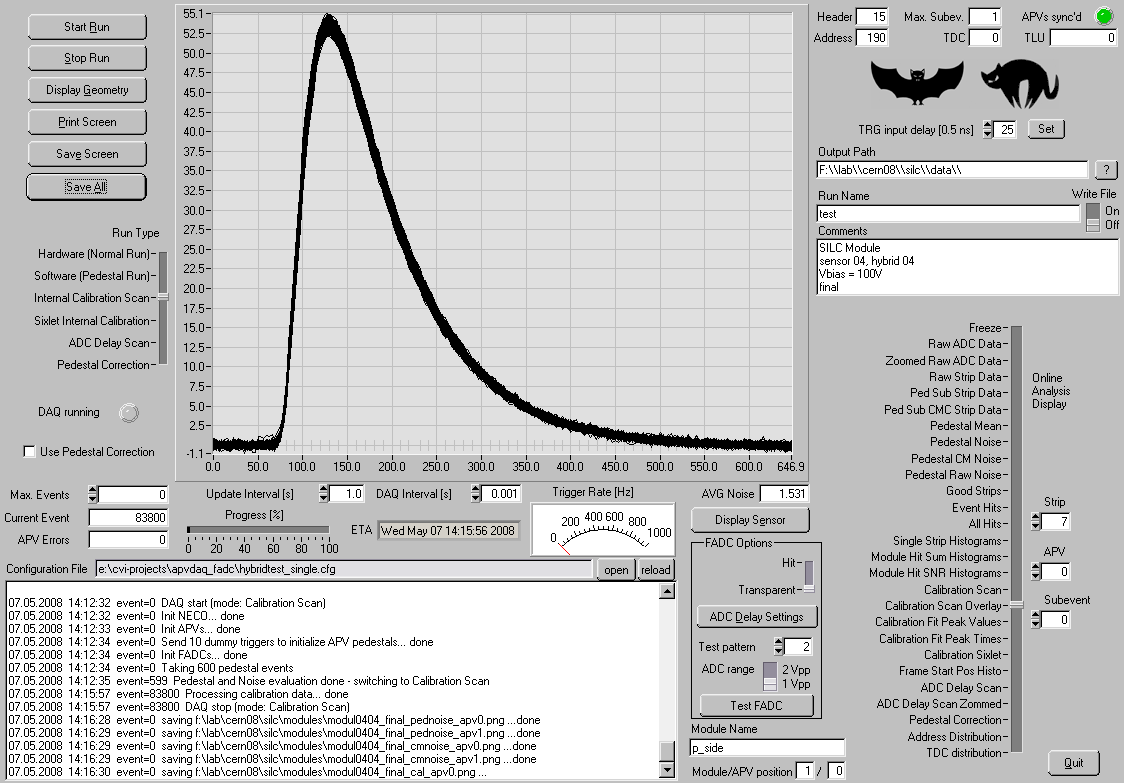

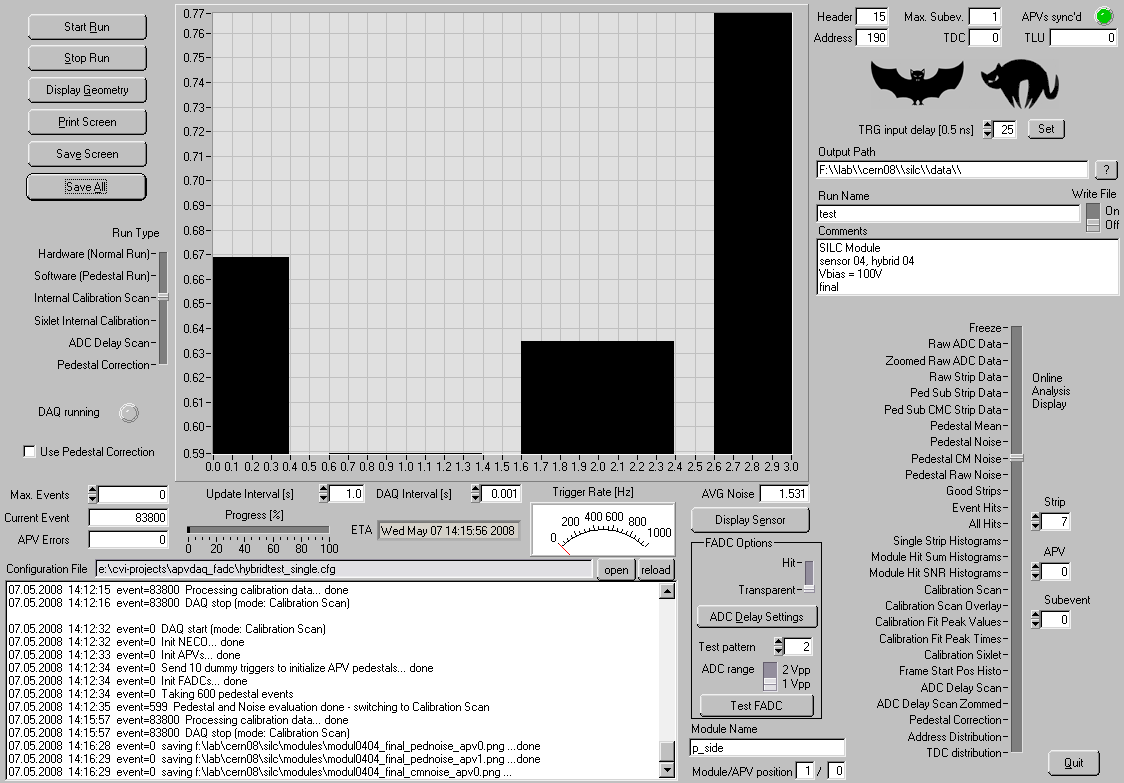

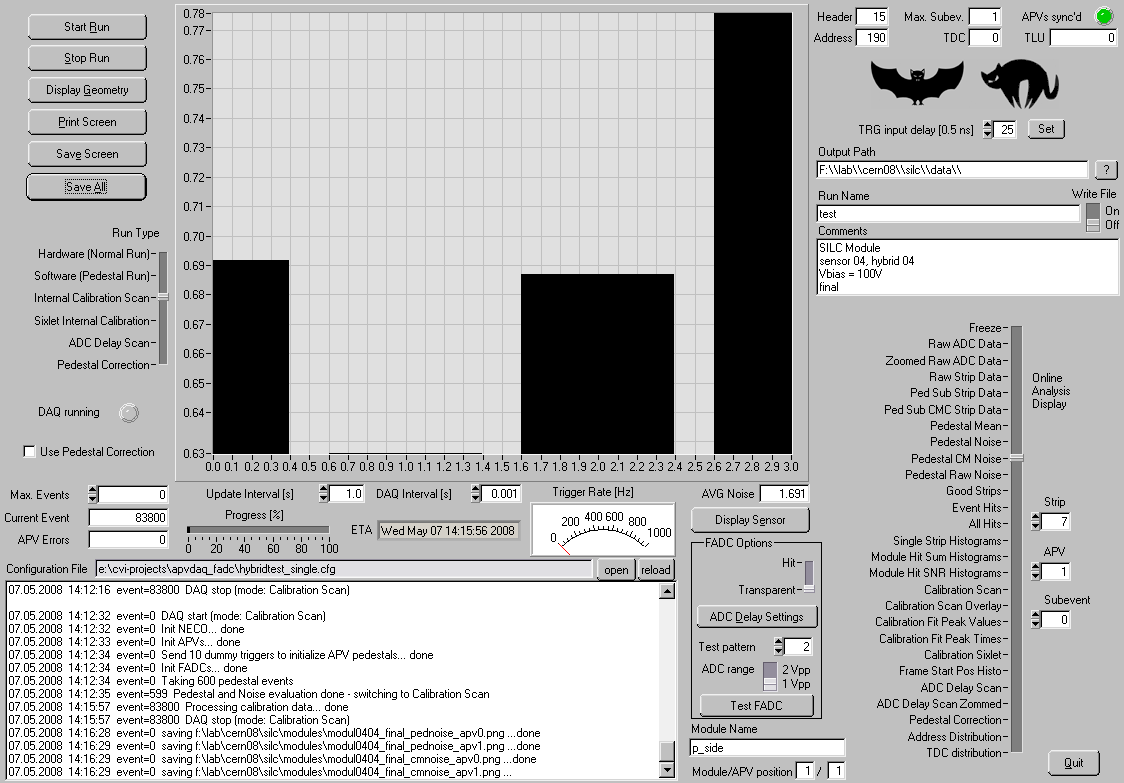

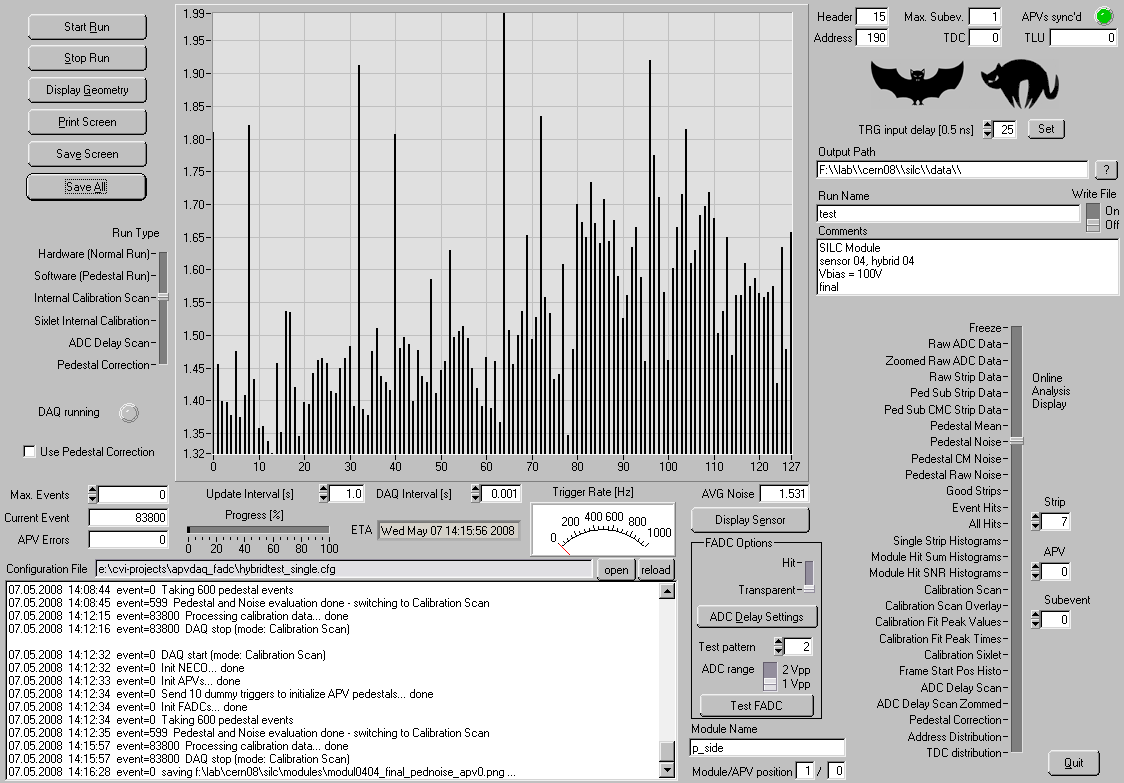

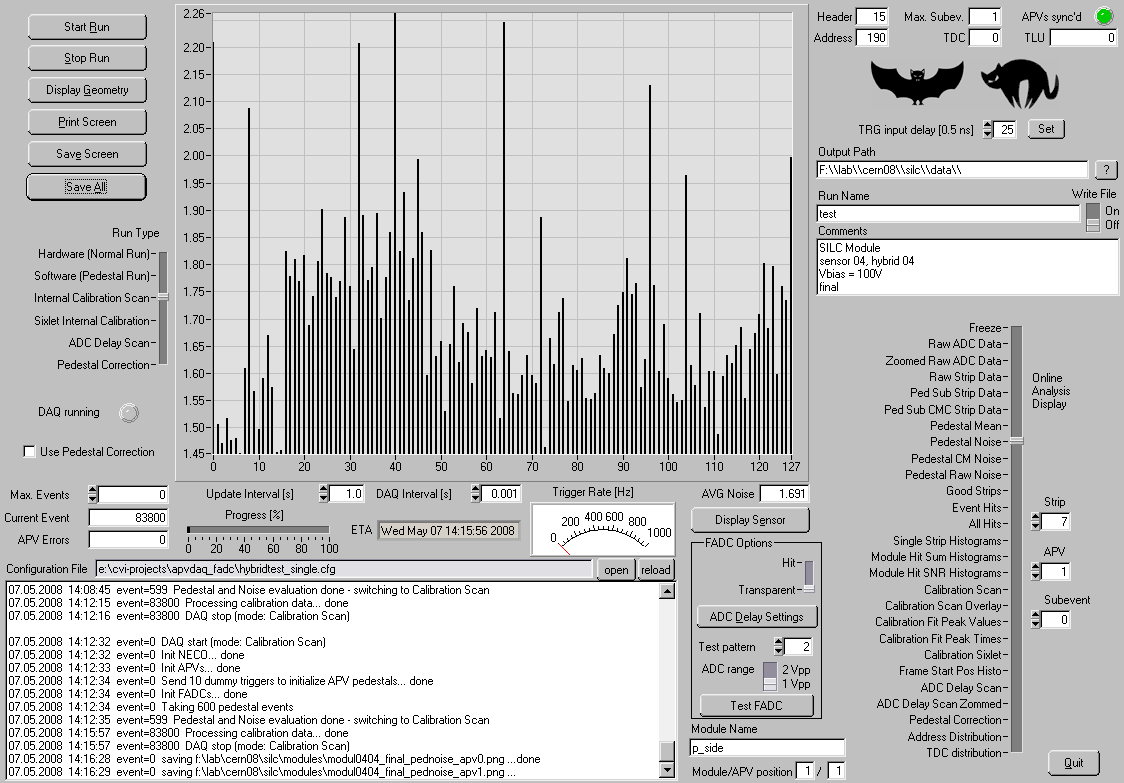

Christian Irmler | SPS Testbeam June08 | module | module 04/04 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100 V) = 27.8 nA

Ibias (200 V) = 32.7 nA |

| Attachment 1: modul0404_1row_cal_apv0.png

|

|

| Attachment 2: modul0404_1row_cal_apv1.png

|

|

| Attachment 3: modul0404_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul0404_1row_cmnoise_apv1.png

|

|

| Attachment 5: modul0404_1row_pednoise_apv0.png

|

|

| Attachment 6: modul0404_1row_pednoise_apv1.png

|

|

| Attachment 7: modul0404_final_cal_apv0.png

|

|

| Attachment 8: modul0404_final_cal_apv1.png

|

|

| Attachment 9: modul0404_final_cmnoise_apv0.png

|

|

| Attachment 10: modul0404_final_cmnoise_apv1.png

|

|

| Attachment 11: modul0404_final_pednoise_apv0.png

|

|

| Attachment 12: modul0404_final_pednoise_apv1.png

|

|

|

|

12

|

Fri May 9 10:00:34 2008 |

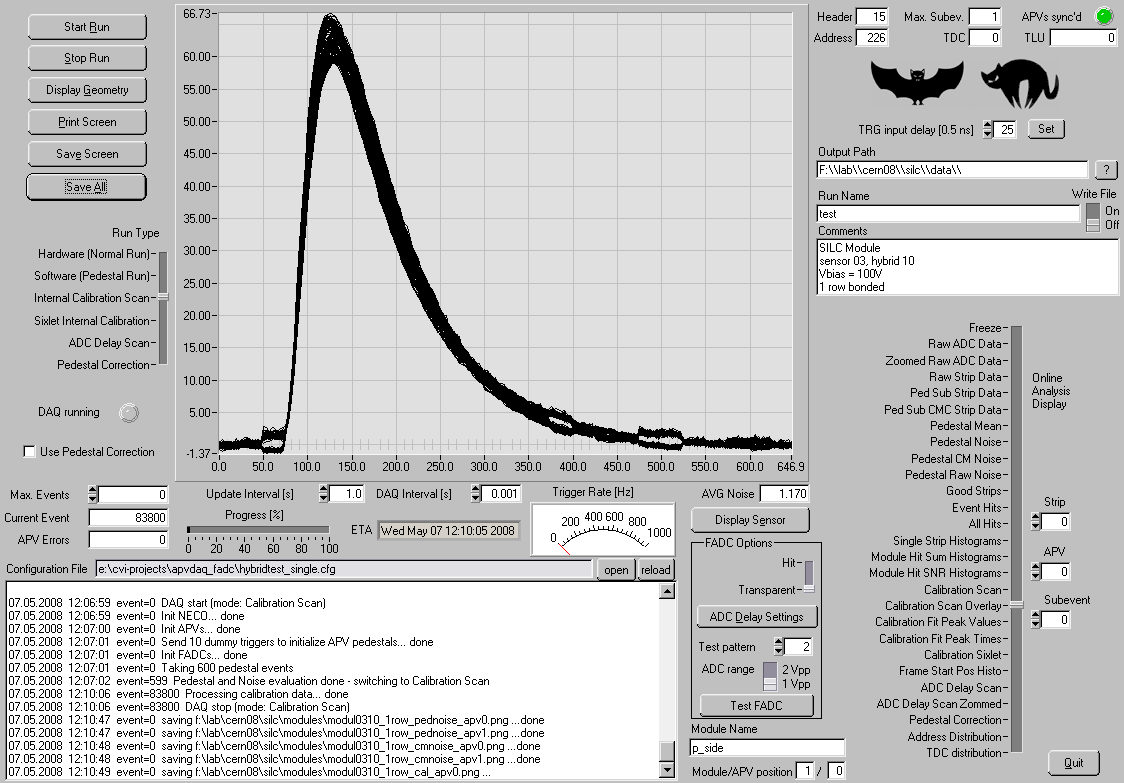

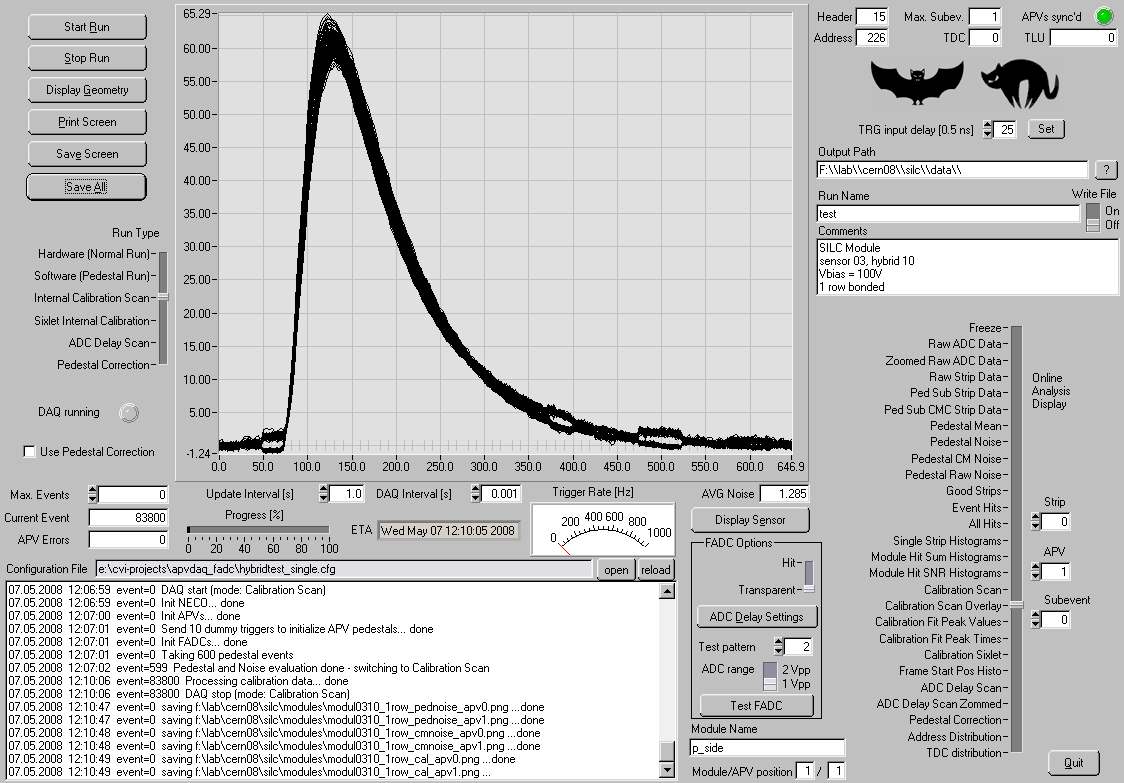

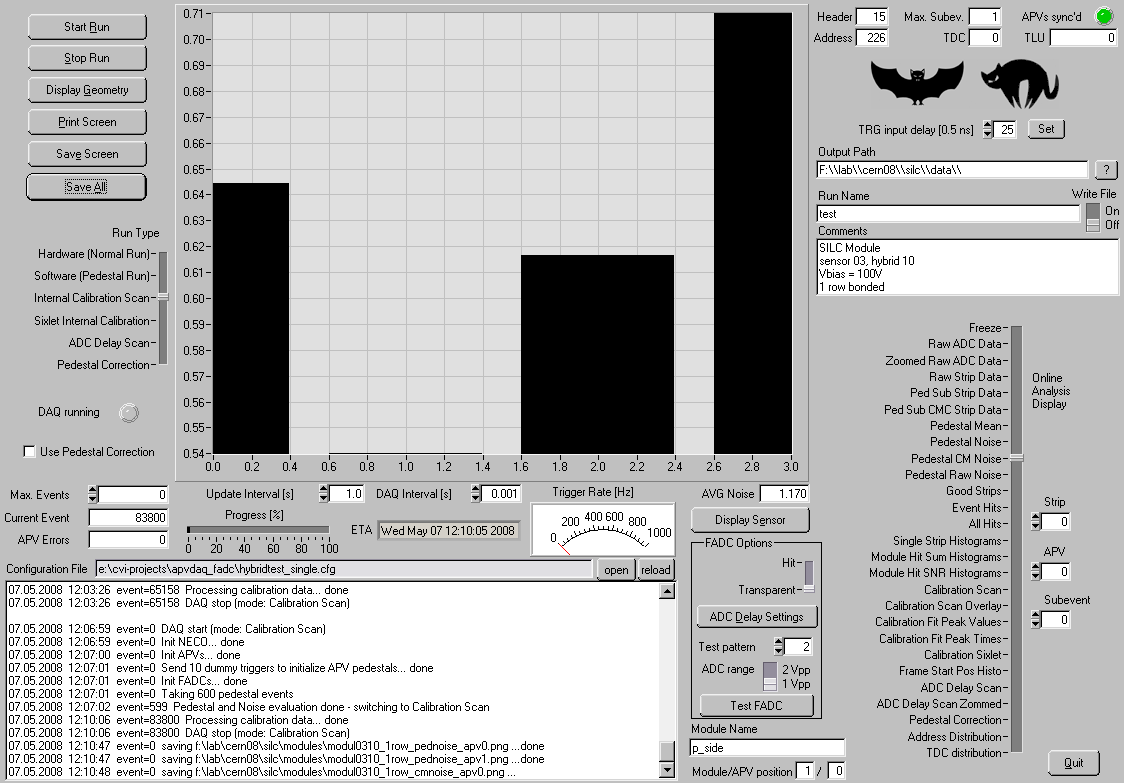

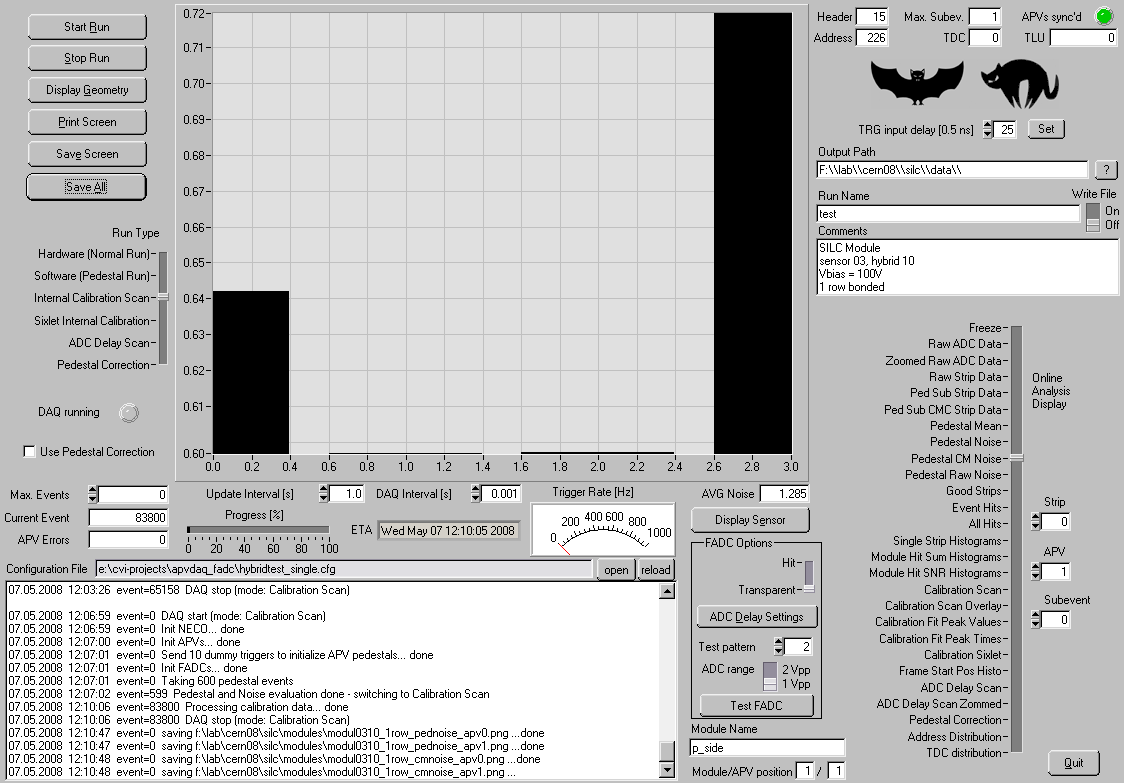

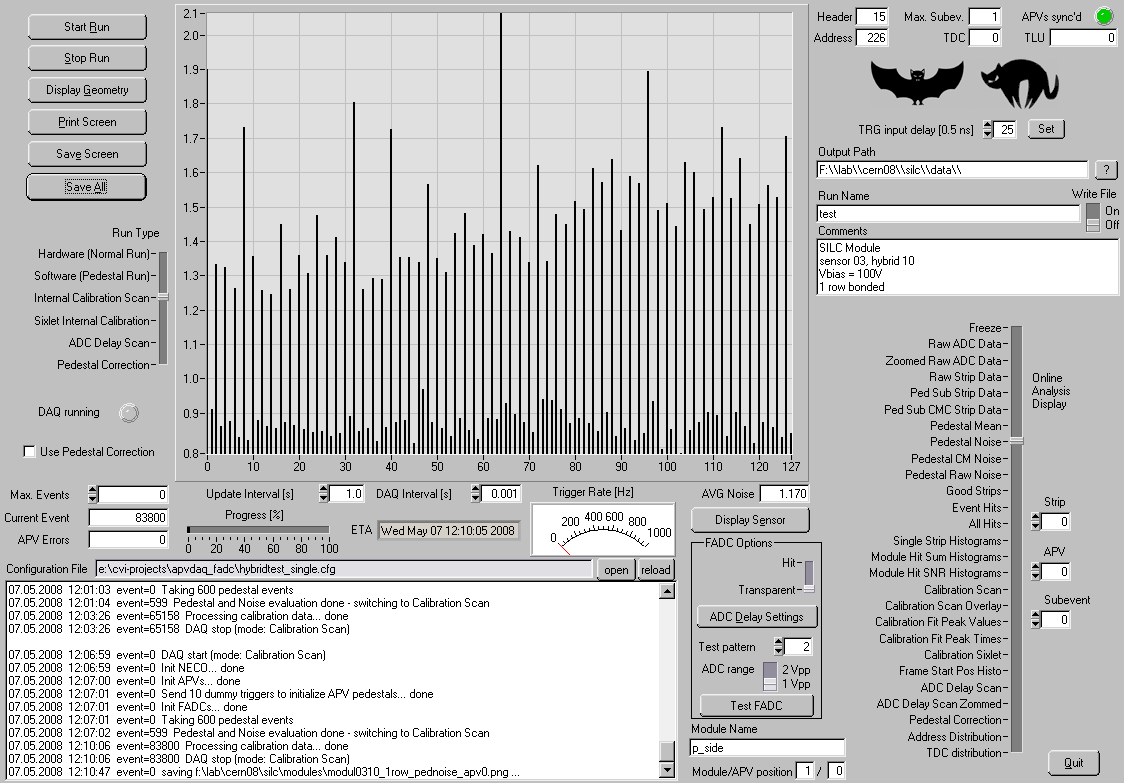

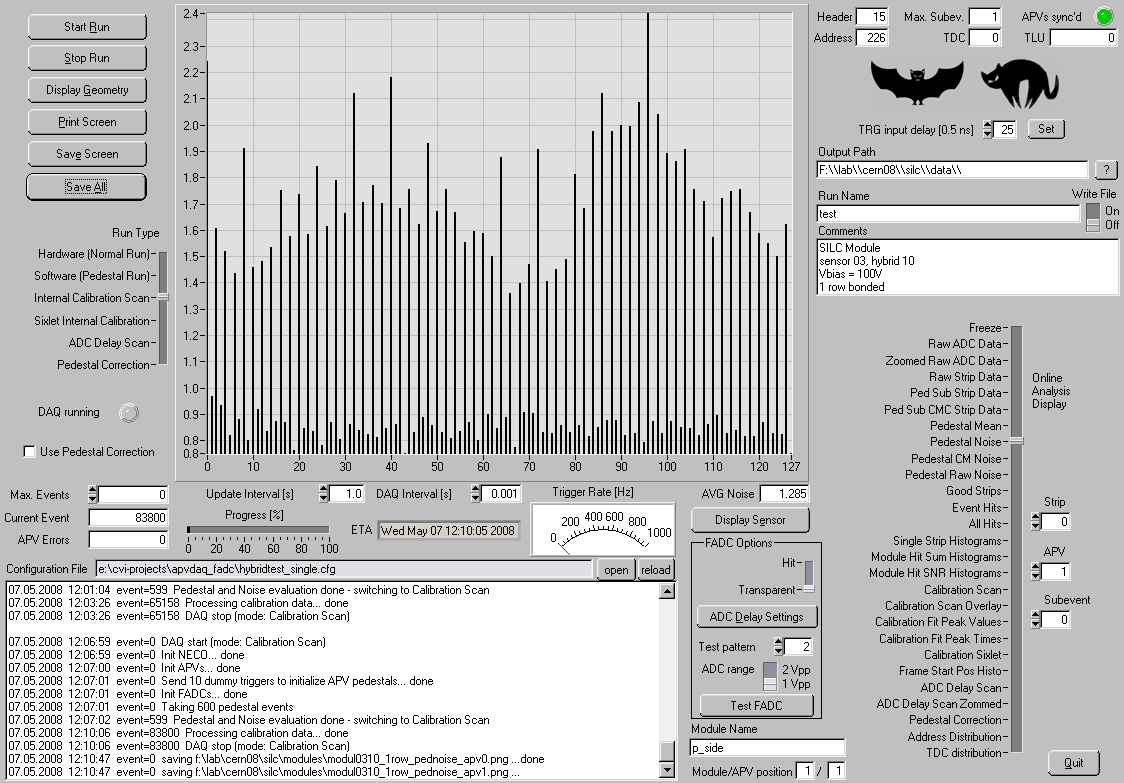

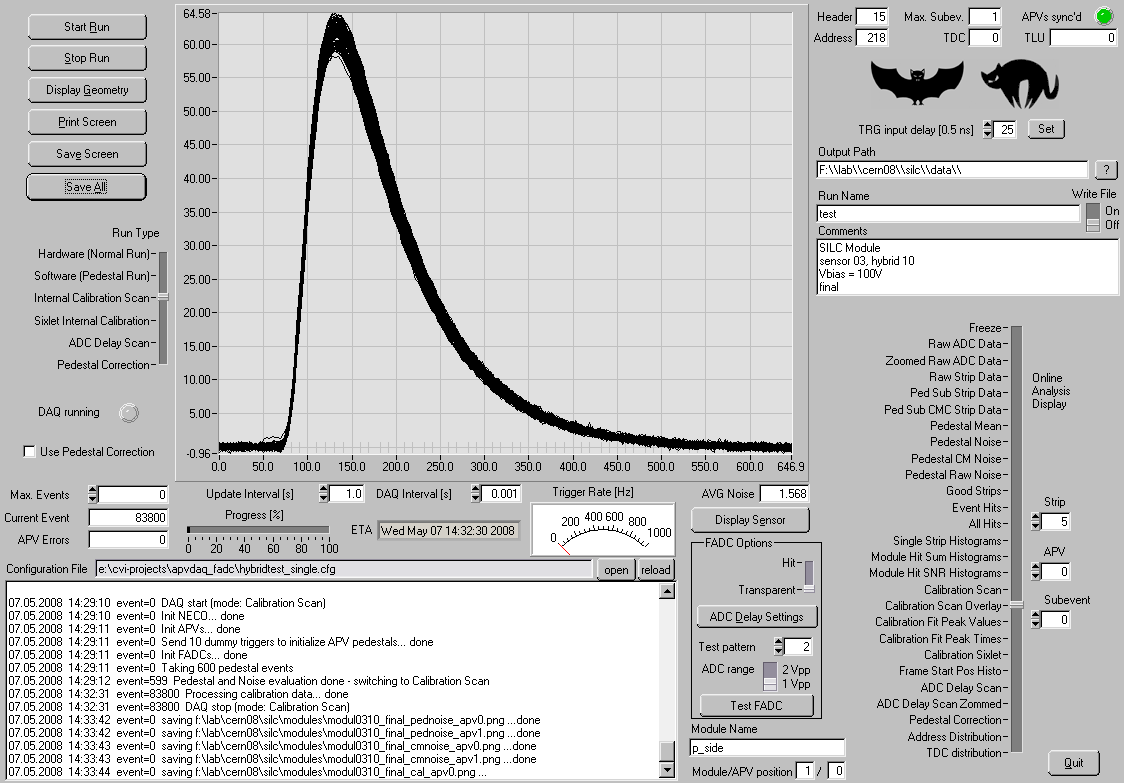

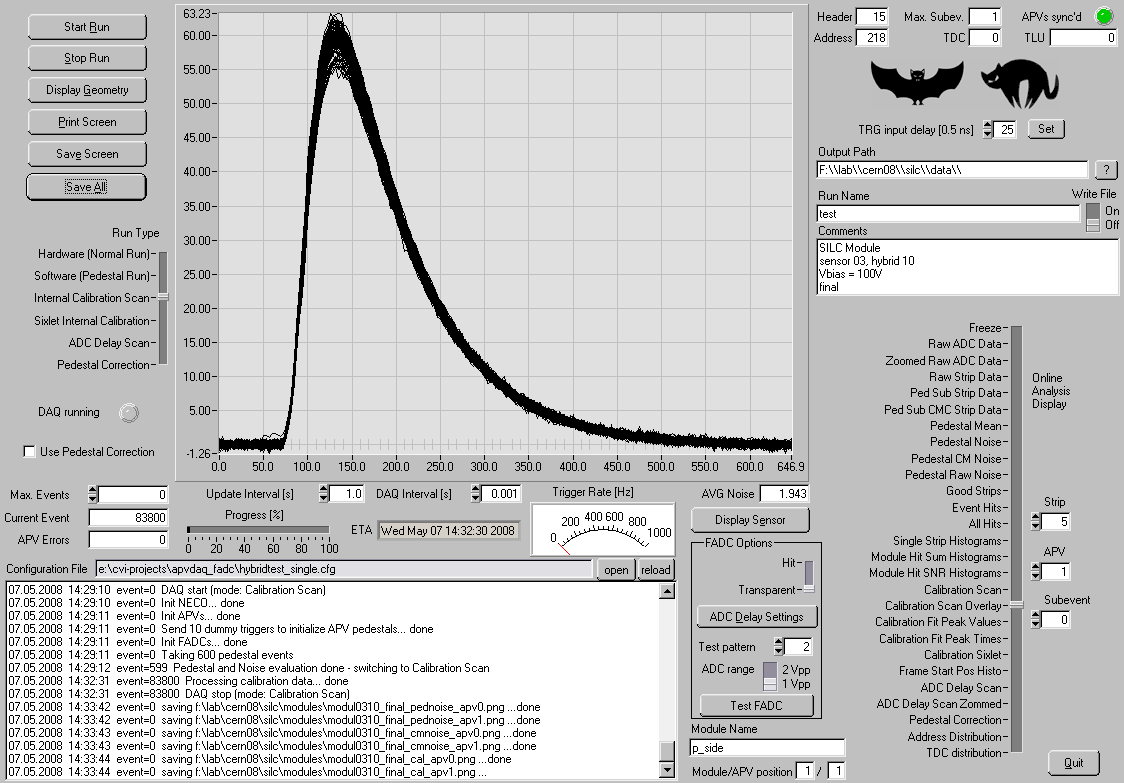

Christian Irmler | SPS Testbeam June08 | module | module 03/10 | properties (noise, intcal), APVs bonded to the sensor |

| Module tested with 1 and 2 rows bonded to the sensor, respectively.

HV = 100 V

Ibias (100 V) = 18.9 nA

Ibias (200 V) = 25.5 nA |

| Attachment 1: modul0310_1row_cal_apv0.png

|

|

| Attachment 2: modul0310_1row_cal_apv1.png

|

|

| Attachment 3: modul0310_1row_cmnoise_apv0.png

|

|

| Attachment 4: modul0310_1row_cmnoise_apv1.png

|

|

| Attachment 5: modul0310_1row_pednoise_apv0.png

|

|

| Attachment 6: modul0310_1row_pednoise_apv1.png

|

|

| Attachment 7: modul0310_final_cal_apv0.png

|

|

| Attachment 8: modul0310_final_cal_apv1.png

|

|

| Attachment 9: modul0310_final_cmnoise_apv0.png

|

|

| Attachment 10: modul0310_final_cmnoise_apv1.png

|

|

| Attachment 11: modul0310_final_pednoise_apv0.png

|

|

| Attachment 12: modul0310_final_pednoise_apv1.png

|

|

|

|

5

|

Wed Apr 30 16:52:17 2008 |

Markus Friedl | BELLE Upgrade | module | micron | micron sensor glued to frame |

soeben haben wir den micron-DSSD (double metal layer) in den 2-teiligen rahmen geklebt und auf beiden seiten

temporäre kapton-stückerln aufgeklebt, über die bias appliziert werden kann. nach trocknung und bonden der

bias-verbindungen (montag, 5.5.2008) wird dieser für sensor-tests zur verfügung stehen. |

|

|

14

|

Tue May 20 14:27:50 2008 |

Markus Friedl | BELLE Upgrade | source | micron | analysis results of source test |

*** NOTE: AFTER THIS MEASUREMENT WE REALIZED THAT BIASING WAS NOT DONE PROPERLY

HENCE THE RESULTS BELOW ARE NOT RELIABLE

(in fact it is surprising that they are not worse) ***

Please find the results of the lab source test on the new Micron module here.

It is read out with 3 + 3 APV chips on either side.

Results table of the source measurement:

p-side n-side

Cluster signal [e] 18361 19434

Strip noise [e] 1142 1193

Avg cluster width 1.91 1.30

Single strip SNR 16.1 16.3

Cluster SNR 11.6 14.3

Strip pitch [um] 50.0 153.5

Apparently, the double metal capacitance is not so bad as expected, even though the Micron sensor does not use

the hourglass crossing scheme. Presumably the dielectric between metal 1 and 2 is rather thick (several um).

Strip noise is roughly the same on both p and n side, so the difference in Cluster SNR (*) only stems from the

unequal cluster width (which is a result of the different pitches).

Peak time precision vs SNR (last plot below) is worse compared to the values obtained with various HPK sensors

in the November 2007 beam test at KEK. However, this is a comparison of source and beam and thus might not be

significant. Let's see what we will get in the SPS beam test next week.

(*) Cluster SNR := sum(signal) / (strip_noise * sqrt(cluster_width) ) |

| Attachment 1: vie_micron_run002_signal.gif

|

|

| Attachment 2: vie_micron_run002_noise.gif

|

|

| Attachment 3: vie_micron_run002_hit.gif

|

|

| Attachment 4: vie_micron_run002_clw.gif

|

|

| Attachment 5: vie_micron_p_run002_tres.gif

|

|

| Attachment 6: vie_micron_n_run002_tres.gif

|

|

| Attachment 7: vie_micron_p_run002_ressnr.gif

|

|

| Attachment 8: vie_micron_n_run002_ressnr.gif

|

|

| Attachment 9: trms_vs_snr_micron_src.gif

|

|

|

|

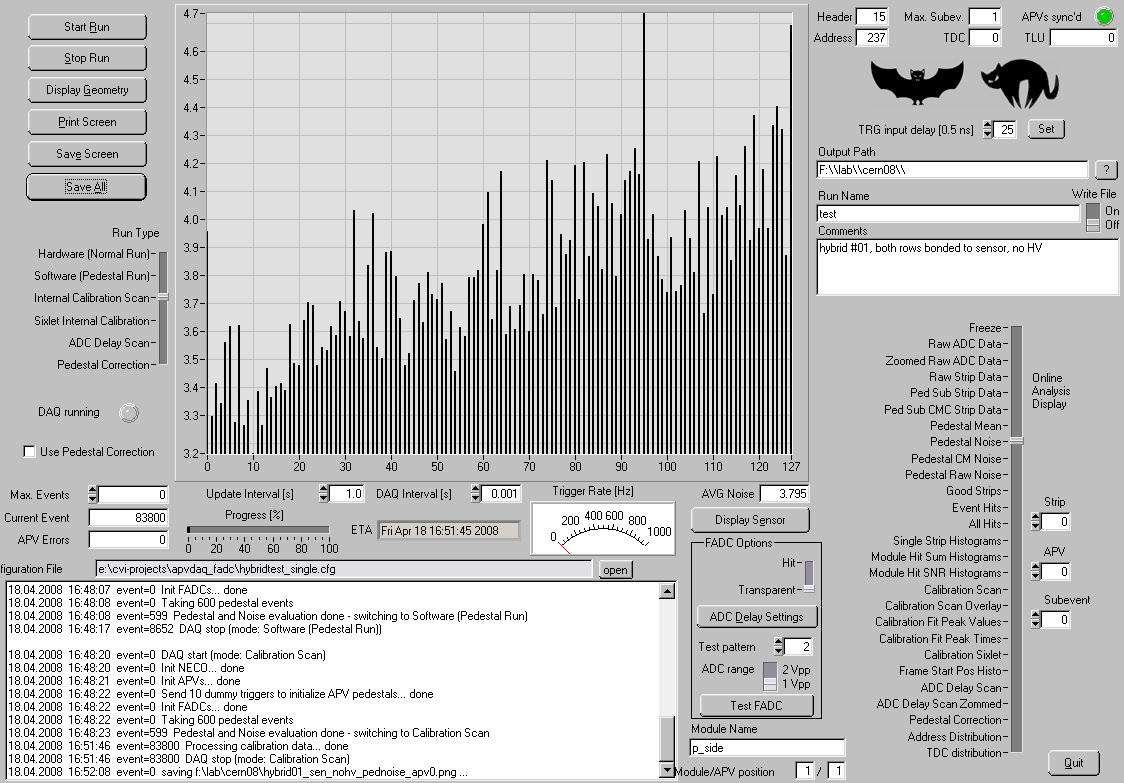

1

|

Fri Apr 18 17:23:26 2008 |

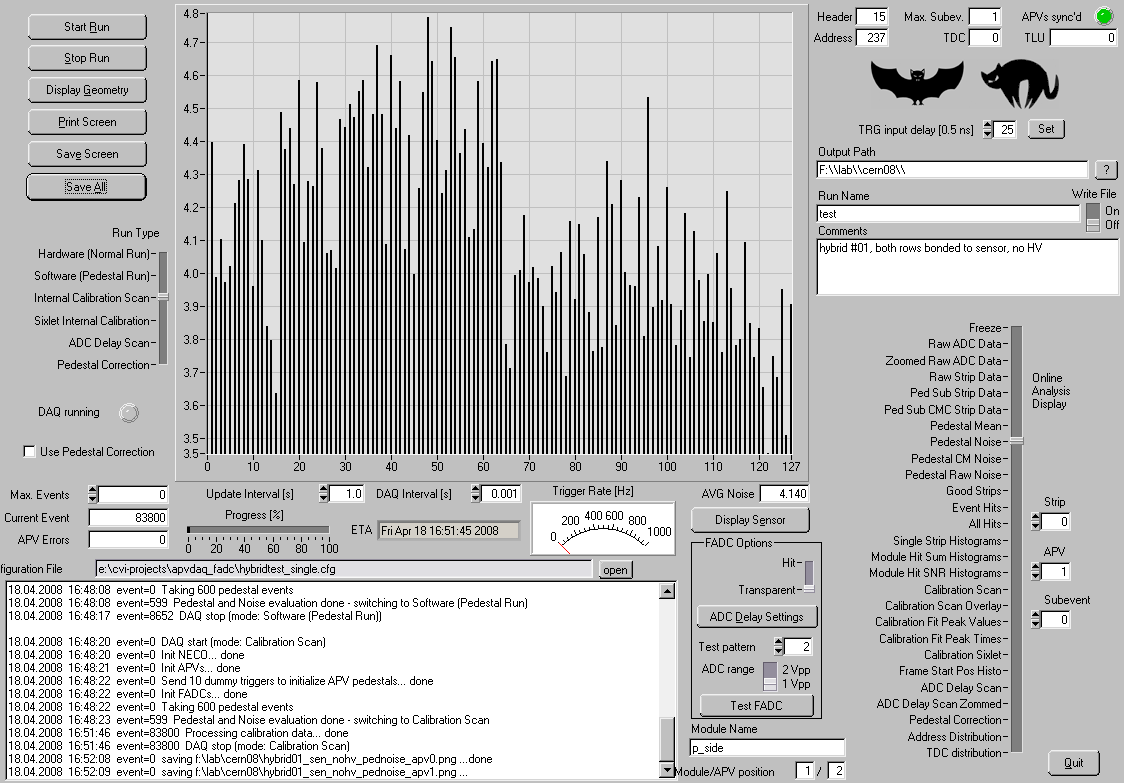

Markus Friedl | SPS Testbeam June08 | hybrid | hybrid 01 | Noise of hybrid 01, sensor fully bonded, no HV |

| HV bias not yet glued to backplane |

| Attachment 1: hybrid01_sen_nohv_pednoise_apv0.png

|

|

| Attachment 2: hybrid01_sen_nohv_pednoise_apv1.png

|

|

|

|

2

|

Tue Apr 22 19:34:09 2008 |

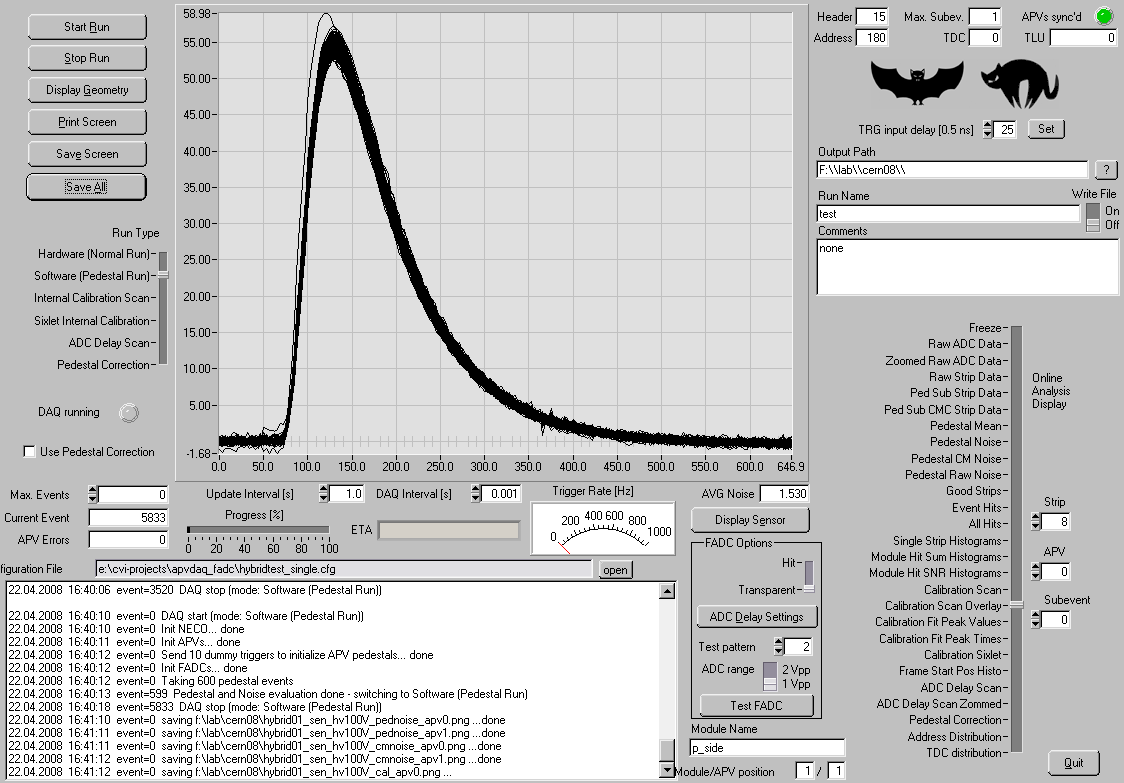

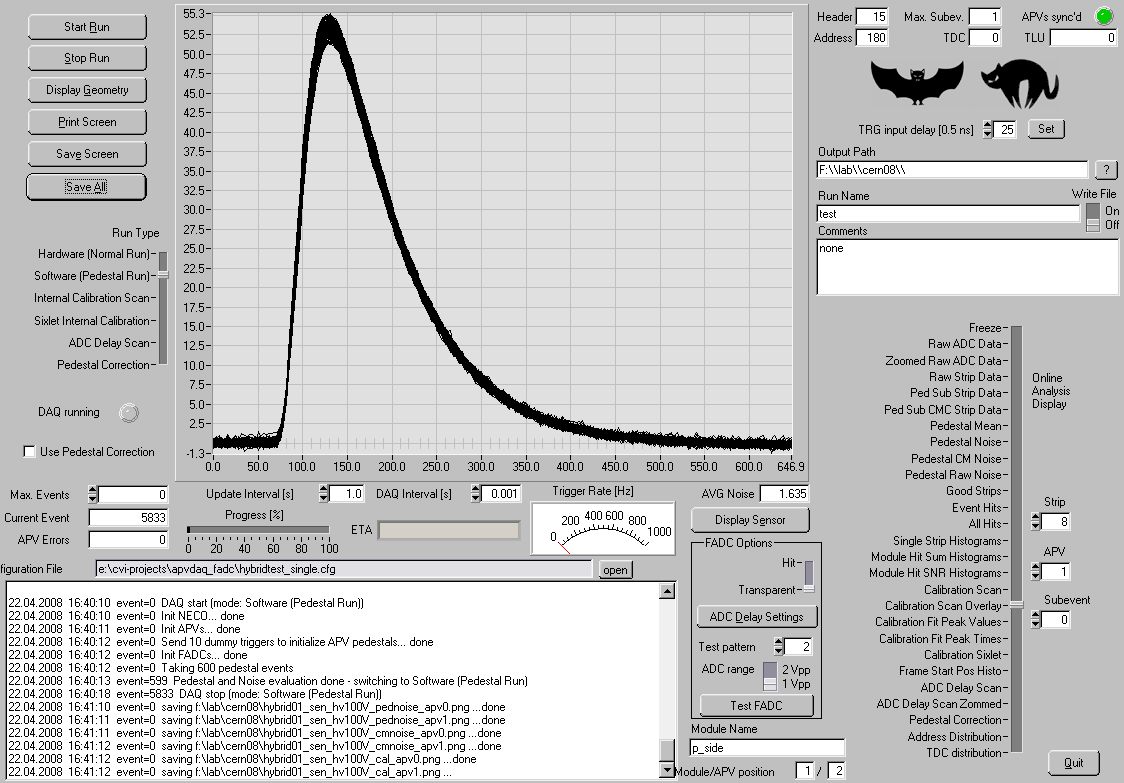

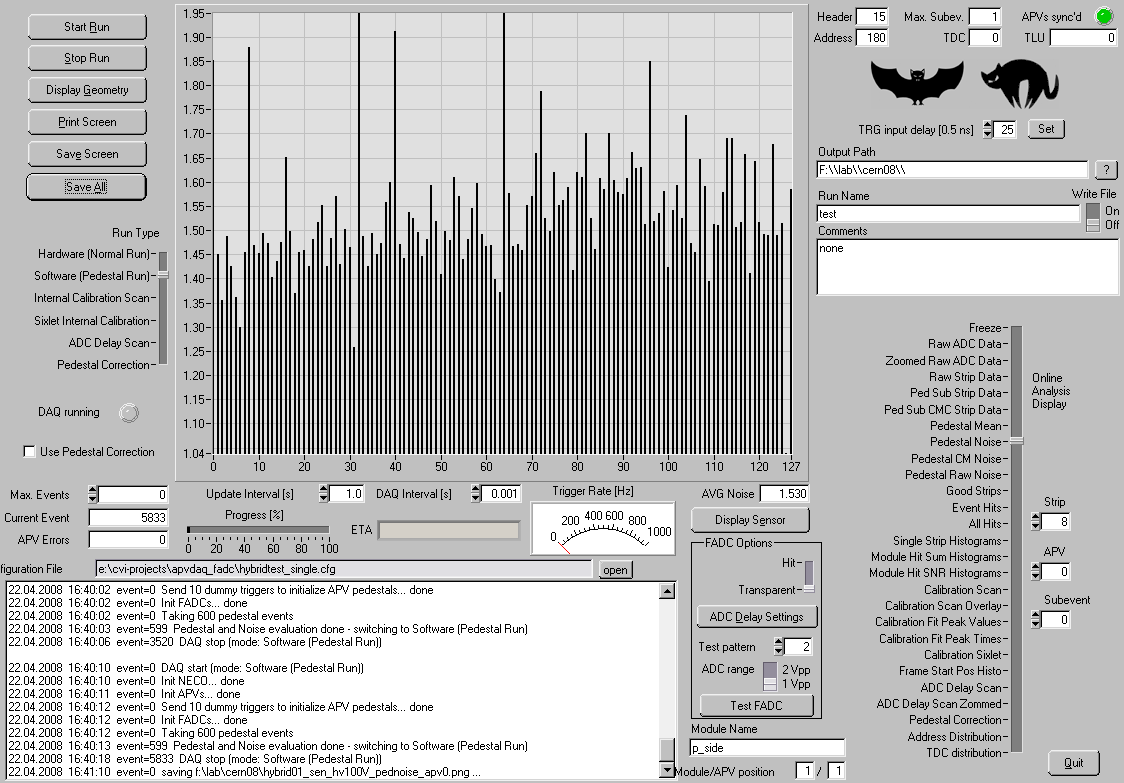

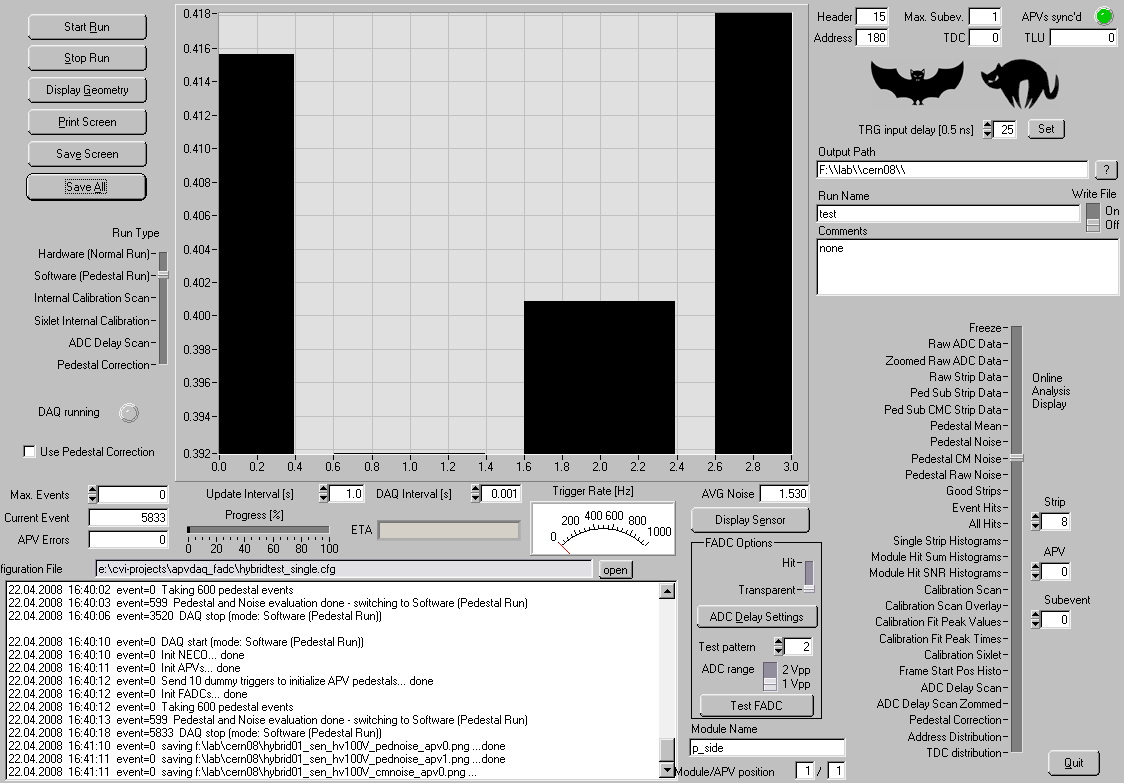

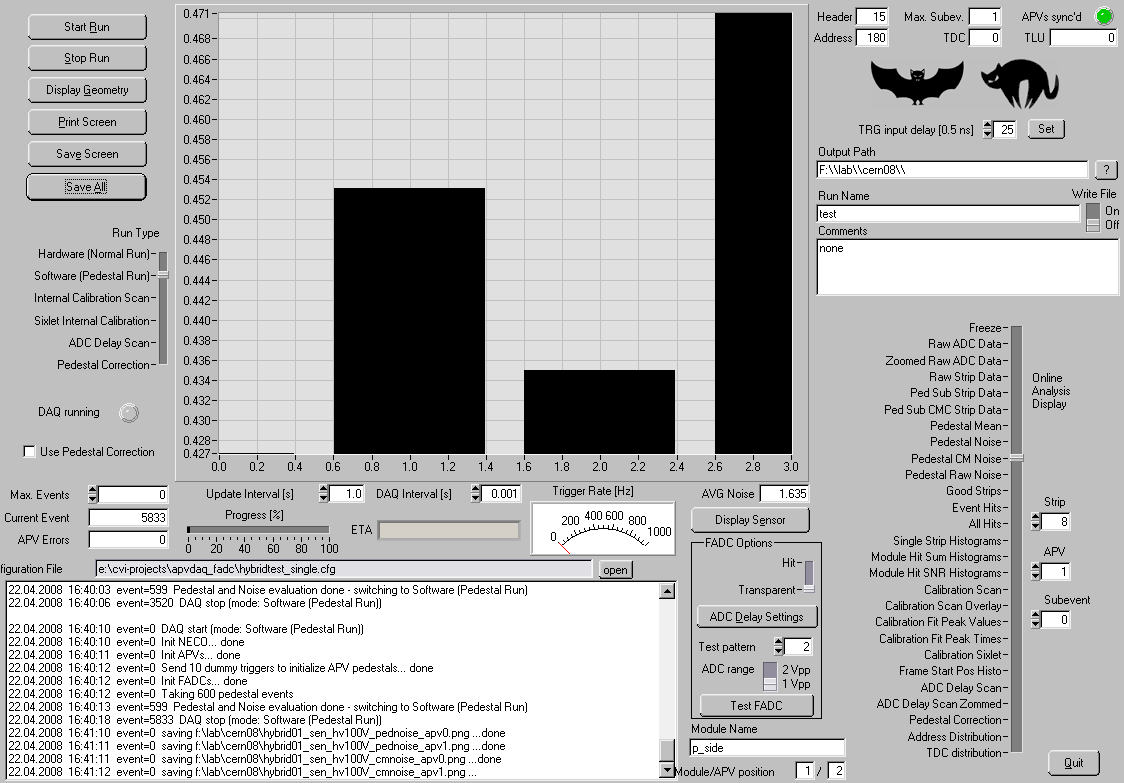

Markus Friedl | SPS Testbeam June08 | module | hybrid 01 | Properties of hybrid 01, sensor fully bonded, HV=100V |

| HV bias glued to backplane, HV=100V |

| Attachment 1: hybrid01_sen_hv100V_cal_apv0.png

|

|

| Attachment 2: hybrid01_sen_hv100V_cal_apv1.png

|

|

| Attachment 3: hybrid01_sen_hv100V_pednoise_apv0.png

|

|

| Attachment 4: hybrid01_sen_hv100V_pednoise_apv1.png

|

|

| Attachment 5: hybrid01_sen_hv100V_cmnoise_apv0.png

|

|

| Attachment 6: hybrid01_sen_hv100V_cmnoise_apv1.png

|

|

|

|

3

|

Wed Apr 23 13:05:05 2008 |

Christian Irmler | SPS Testbeam June08 | source | hybrid 01 | time correlation between TDC and sensor measurement -> 3.1 ns RMS |

|

| Attachment 1: vie_run001_tpeak_vs_TDC.gif

|

|

|

|

4

|

Wed Apr 23 13:37:18 2008 |

Markus Friedl | SPS Testbeam June08 | source | hybrid 01 | analysis results of source test |

Ignore the "KEK November 2007" title - that's a legacy and is already changed :-)

As of now, there is no distinction in 16 separate zones. However, the gaps between the the zones are clearly visible in the Hit Profile, as the edge strips on both sides have a larger sensitive area and thus collect more hits than other strips; hence the spikes in the (otherwise pretty gaussian) beam profile. There is a single strip with no entries in the center - that's the one that suffered from the bias bond repair action.

SNR=21 (peak mode) is pretty healthy and fits to similar detectors operated with APV25.

All data was taken in multi-peak mode with subsequent hit fitting to obtain amplitude and timing (see separate posting for timing precision).

The verbose output of the analysis is pasted below.

Analysis of vie_run001

Peak Mode, 3 x 200 initevents (first 10 skipped) + 99400 events

Number hybrids: 1 number zones: 2 number sensors: 1

Using calibration file vie_cal001

No pedestal correction file

Seed/Neighbor/Cluster/Noisy Strips Cuts [RMS noise]: 5.0/3.0/5.0

Min. hitlength: 3

Comments:

SILC module 01

HV=100V, 40MHz, Tp=50ns, 30ns

Sr90 1mCi , black cloth cover

Analysis date: 23.04.2008 13:25:09

Analysis settings:

runname: vie_run001_cluster

clock: 40.00 MHz

datafilepath: data/

outputpath: output/

subevents: 6

fitmode: 2 (cal. fit)

options: h

Results:

ModuleName ZoneType Ch OKCh OK% Entries MClW MPSignal Noise MPSNR HpSE Occup

p_side JP single sensor 256 256 100.0 90385 2.53 21546.1 729.4 20.68 0.53 1.81 |

| Attachment 1: vie_run001_cluster_sig_0.gif

|

|

| Attachment 2: vie_run001_cluster_noi_0.gif

|

|

| Attachment 3: vie_run001_cluster_hit_0.gif

|

|

| Attachment 4: vie_run001_cluster_clw_0.gif

|

|

|

|

33

|

Thu Jun 5 10:33:46 2014 |

Benedikt Würkner | Belle II | source | Silc Module | Silc Angle Measurement 1° |

Measured the Silc 03/10 Module using the Sr90 Source to have a comparison for the Eta-Distribution at different angles.

Data can be found on heros in: /home/medialib/LAB_Silc_Angle.

Plots made with TuxOA for all different regions can be found in /home/users/bwuerkner/plots/.

|

|

|

34

|

Thu Jun 5 10:34:06 2014 |

Benedikt Würkner | Belle II | source | Silc Module | Silc Angle Measurement 4° |

Measured the Silc 03/10 Module using the Sr90 Source to have a comparison for the Eta-Distribution at different angles.

Data can be found on heros in: /home/medialib/LAB_Silc_Angle.

Plots made with TuxOA for all different regions can be found in /home/users/bwuerkner/plots/.

|

|

|

35

|

Thu Jun 5 10:34:29 2014 |

Benedikt Würkner | Belle II | source | Silc Module | Silc Angle Measurement 7° |

Measured the Silc 03/10 Module using the Sr90 Source to have a comparison for the Eta-Distribution at different angles.

Data can be found on heros in: /home/medialib/LAB_Silc_Angle.

Plots made with TuxOA for all different regions can be found in /home/users/bwuerkner/plots/.

|

|

|

36

|

Thu Jun 5 10:34:45 2014 |

Benedikt Würkner | Belle II | source | Silc Module | Silc Angle Measurement 10° |

Measured the Silc 03/10 Module using the Sr90 Source to have a comparison for the Eta-Distribution at different angles.

Data can be found on heros in: /home/medialib/LAB_Silc_Angle.

Plots made with TuxOA for all different regions can be found in /home/users/bwuerkner/plots/.

|

|

|

59

|

Mon Nov 30 18:45:49 2015 |

Hao Yin | Belle II | system | PedestalRun_Cold | |

ADC Cold diff to hot: 1-3 adc delay config (max 1.5 ns), FIRRun_Cold_001

|

|

|

54

|

Mon Nov 30 17:13:47 2015 |

Hao Yin | Belle II | system | PedestalRun | |

ADC Hot, FIRRun001

room temp pedrun |